Long-opening-time primer and preparation method thereof

A technology of open time and primer, which is applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of short open time of the primer, and achieve improved medium resistance and Adhesive performance, long open time, effect of reducing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

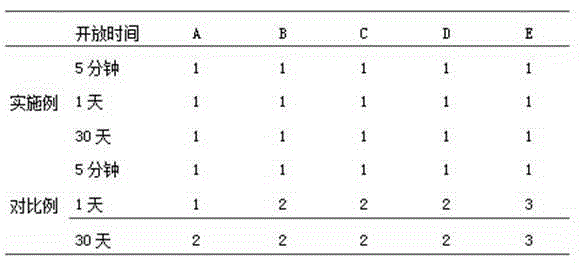

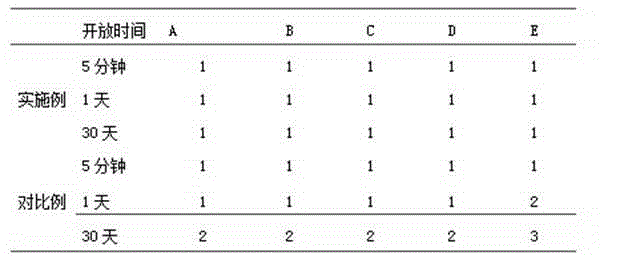

Examples

Embodiment

[0054] Silane-terminated aliphatic isocyanate prepolymers were prepared as follows:

[0055] 350 grams of polyoxypropylene trihydric alcohol (average molecular weight 350) is added in the reactor with mechanical stirring, nitrogen protection and heating device. Heated to 50°C under the protection of nitrogen, then added 1512 grams of 1,6-hexamethylene diisocyanate biuret, stirred evenly, added 1 gram of dibutyltin dilaurate, kept at 70°C and stirred for 4 hours, then added mercaptopropyl trimethoxy 1176g of base silane, and continue to keep warm at 50°C for 4h to obtain a silane-terminated aliphatic isocyanate prepolymer.

[0056] Adhesion promoters are prepared as follows:

[0057] 269 grams of N-(2-aminoethyl)-3-aminopropyltriethoxysilane was added to the reactor equipped with mechanical stirring, nitrogen protection and heating device. Heated to 80°C under the protection of nitrogen, then added 236 grams of (3-glycidoxypropyl)trimethoxysilane, stirred evenly, and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com