Polyester elastomer composition

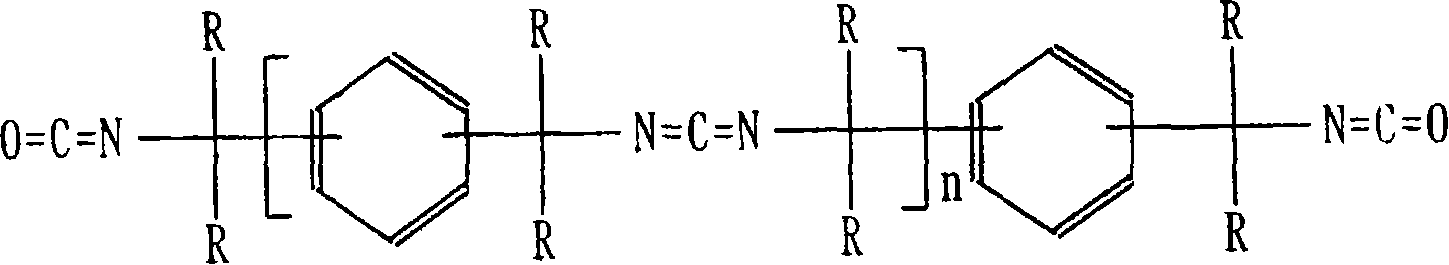

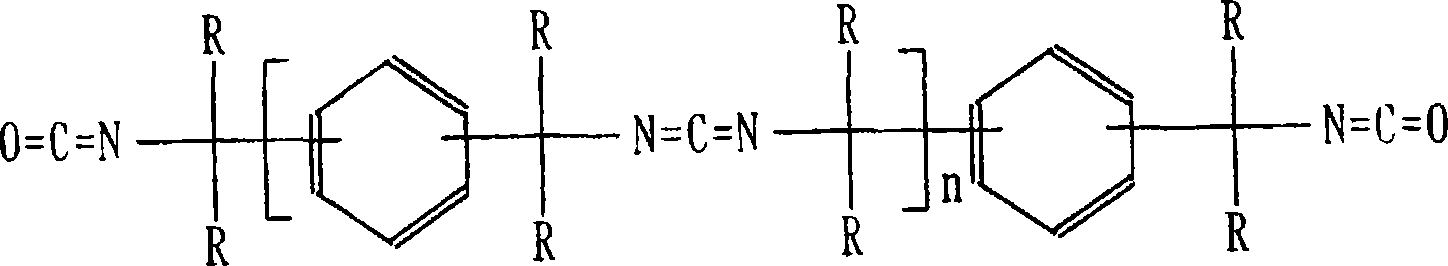

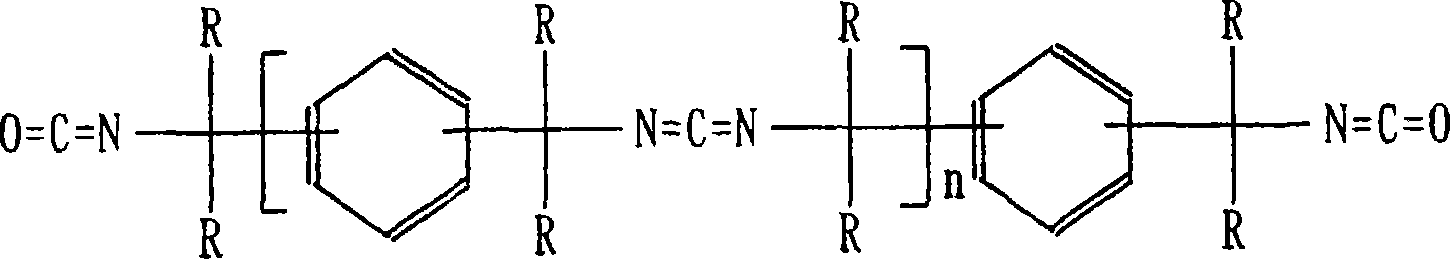

A technique of polyester elastomer and composition, which is applied in the field of polyester elastomer composition, and can solve problems such as concentration reduction and inability to fully capture polycarbodiimide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0072] The polyester elastomer (A), epoxy compound (B), and polycarbodiimide compound (C) were mixed according to the compounding ratio (unit: parts by weight) described in Table 1. Then, it was melt-kneaded and extruded at 250° C. with a 30 mmφ twin-screw extruder, and the obtained strands were cooled in a water tank, and then sheared with a pelletizer to obtain pellets of the polyester elastomer composition. The obtained pellets were dried at 120° C. for 5 hours while flowing nitrogen gas.

[0073] Using the above pellets, a test piece for tensile test and a test piece for Charpy impact test were molded by an injection molding machine at 260°C.

[0074] The evaluation results are described in Table 1. By adding epoxy compounds and specific carbodiimide compounds, mechanical properties can be maintained, water resistance test results become better, and hydrolysis resistance is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com