Method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide

A technology of zinc dibenzyl dithiocarbamate and rubber vulcanization, applied in organic chemistry and other directions, can solve the problems of product dependence and low initial melting point, and achieve the effects of less environmental pollution, long shelf life and long scorch time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

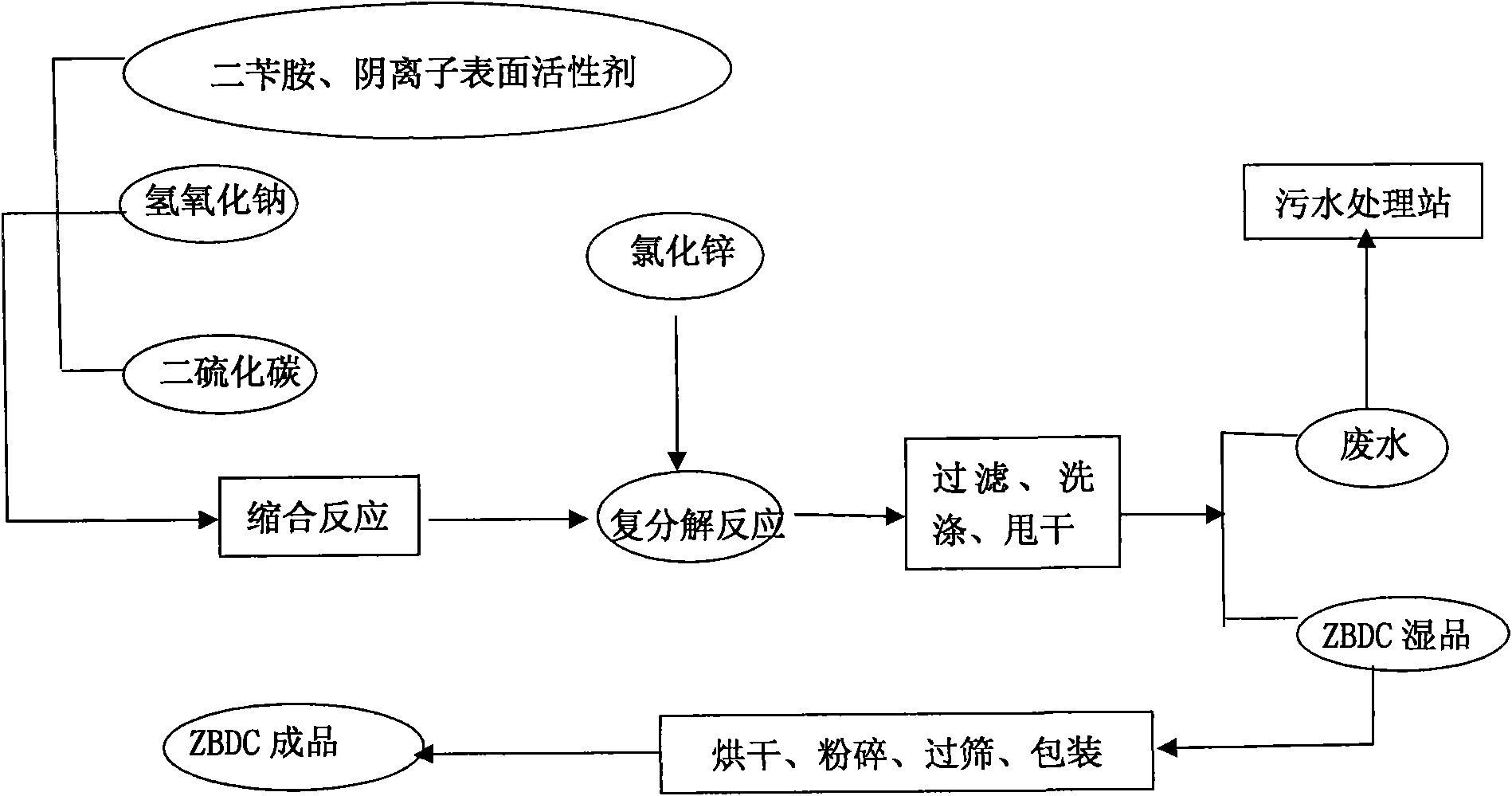

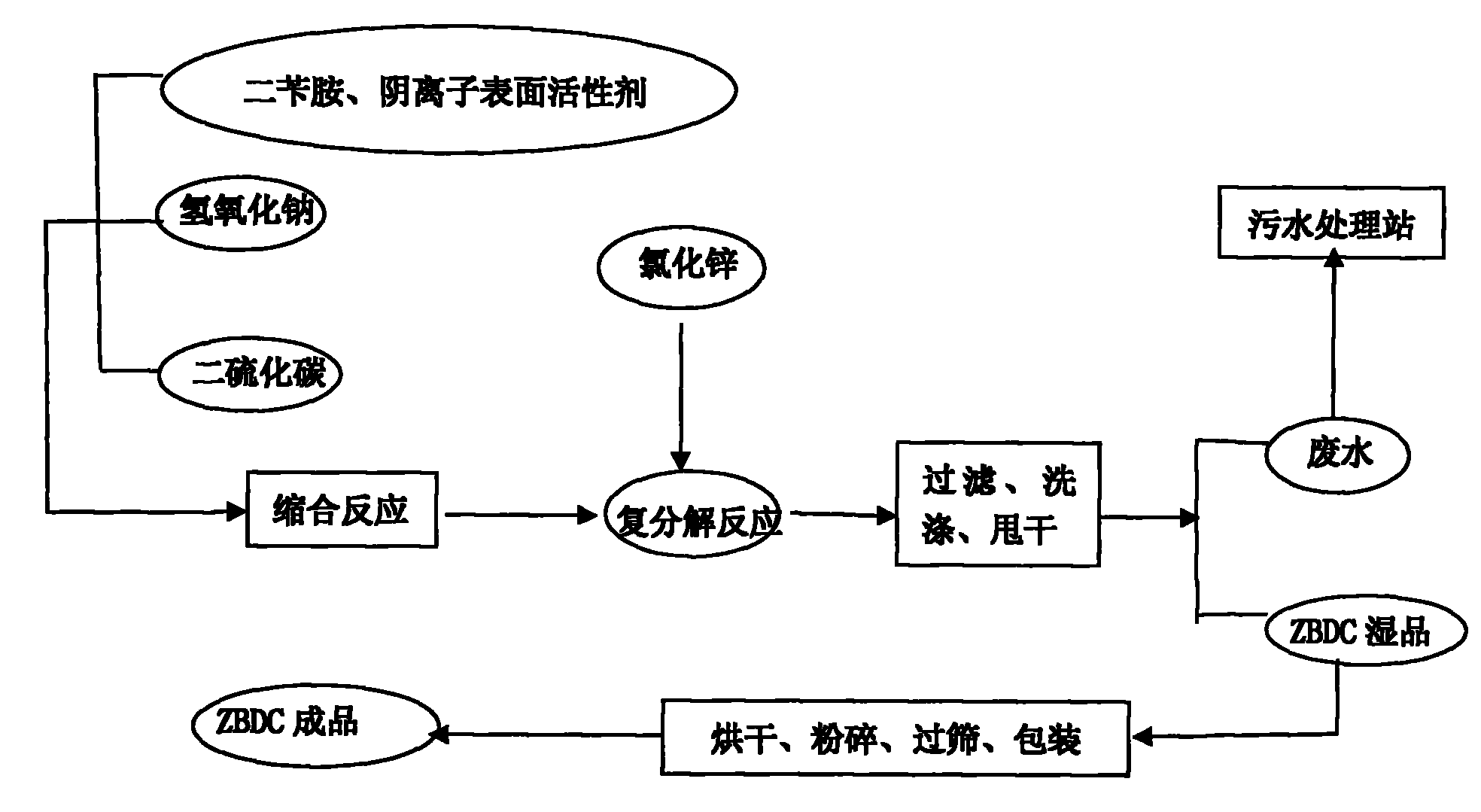

Method used

Image

Examples

Embodiment 1

[0028] The raw materials used in this embodiment and their mol ratio are:

[0029] Dibenzylamine: carbon disulfide: sodium hydroxide: anionic surfactant: zinc chloride: sulfuric acid=1: 1.1: 1.08: 0.020: 0.55: 0.008 mol. The specific process is as follows: in the reaction kettle filled with purified water, add a specified amount of dibenzylamine, sodium hydroxide and anionic surfactant in sequence under stirring, wherein the anionic surfactant is sodium dodecylsulfonate, The temperature was lowered to 13°C, and a specified amount of carbon disulfide liquid was started to be added dropwise, and the control time was 6 hours. After the dropwise addition, stir for 0.5°C, control the temperature at 31° C., and add zinc chloride solution dropwise to carry out metathesis reaction. After the reaction, adjust the pH value of the reaction solution to 7 with sulfuric acid, that is, the reaction ends. After stirring for 1.5 hours, solid-liquid separation is carried out, the liquid is di...

Embodiment 2

[0031] The raw materials used in this embodiment and their mol ratio are:

[0032]Dibenzylamine: carbon disulfide: sodium hydroxide: anionic surfactant: zinc chloride: sulfuric acid=1: 1.15: 1.12: 0.022: 0.53: 0.008mol. The specific process is as follows: in the reaction kettle filled with purified water, add a specified amount of dibenzylamine, sodium hydroxide and anionic surfactant in sequence under stirring, wherein the anionic surfactant is sodium dodecylsulfonate, The temperature was lowered to 16°C, and a specified amount of carbon disulfide liquid was started to be added dropwise, and the control time was 6.5 hours. After completion of the dropwise addition, stir for 0.8 hours, control the temperature of 35° C., and add zinc chloride solution dropwise to carry out metathesis reaction. After the reaction was finished, the pH value of the reaction solution was adjusted to 8 with sulfuric acid, that is, the reaction was finished. After stirring for 2 hours, solid-liquid...

Embodiment 3

[0034] The raw materials used in this embodiment and their mol ratio are:

[0035] Dibenzylamine: carbon disulfide: sodium hydroxide: anionic surfactant: zinc chloride: sulfuric acid=1: 1.18: 1.16: 0.025: 0.57: 0.008 mol. The specific process is: into the reaction kettle filled with purified water, add the specified amount of dibenzylamine, sodium hydroxide and anionic surfactant in turn under stirring, wherein the anionic surfactant is regarded as sodium dodecylsulfonate , the temperature was lowered to 18°C, and a specified amount of carbon disulfide liquid was started to be added dropwise, and the control time was 7 hours. After completion of the dropwise addition, stir for 1 hour, control the temperature of 38°C, and add zinc chloride solution dropwise to carry out metathesis reaction. After the reaction, the pH value of the reaction solution was adjusted to 9 with sulfuric acid, and the reaction was completed. After stirring for 1.5 hours, solid-liquid separation is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com