Aircraft tire flap rubber

A technology for aviation tires and tape rubber, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of low hardness and low strength of the tape rubber, and cannot meet the high performance requirements of the tape rubber for aviation tires. The effect of prolonging scorch time, increasing hardness and strength, improving processing and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

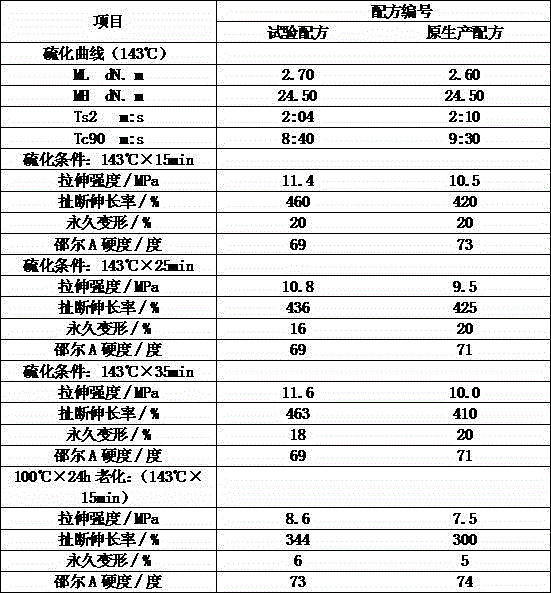

[0013] A kind of aviation tire pad rubber is made by the following raw materials by weight ratio through internal mixer according to conventional technology:

[0014] Raw rubber system: 20# standard rubber: 50 parts, styrene-butadiene rubber: 50 parts, reclaimed rubber: 70 parts; zinc oxide 4 parts, stearic acid 3 parts, antioxidant A 0.5 parts, antioxidant D 1.5 parts, paraffin wax 1.5 parts 3 parts of asphalt; 58 parts of N660 carbon black; 6 parts of aromatic oil, 2.65 parts of sulfur, 0.15 parts of accelerator TMTD, 1.5 parts of accelerator MBTS, and 0.2 parts of anti-scorch agent CTP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com