Rubber material for metal and rubber composite shock-absorbent product

A rubber material and rubber technology, which is applied in the field of rubber materials for metal and rubber composite products, can solve the problem of aging resistance, adhesive performance and product creep that cannot meet the requirements of vehicle operation and cannot withstand tension, compression, bending, and torsional loads and other problems, to achieve the effect of excellent weathering resistance, good mechanical properties and long scorch time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Natural rubber and chlorosulfonated polyethylene are used as rubber materials, and the proportioning is as follows in parts by weight:

[0025] Rubber 100, including: natural rubber SCR-5 75, chlorosulfonated polyethylene-40 25

[0026] Vulcanizing agent 2.1, including: sulfur 0.6, vulcanizing crosslinking agent 268 1.5

[0027] Accelerator 2.1, including: sulfenamide NOBS 1.5, thiuram TT 0.6

[0028] Anti-aging agent 4.5, including: chemical anti-aging agent 4010NA 1.0, chemical anti-aging agent D

[0029] 1.5. Physical anti-aging agent - protective wax FLY-3 2.0

[0030] Reinforcing agent Semi-reinforcing carbon black 32.0

[0031] Active agent 6.3, of which: zinc oxide 5.0, stearic acid 1.3

[0032] Softening Plasticizer - Solid Coumarone 4.0

[0033] Anti-scorch agent C.T.P 0.5.

[0034] serial number

[0035] 5

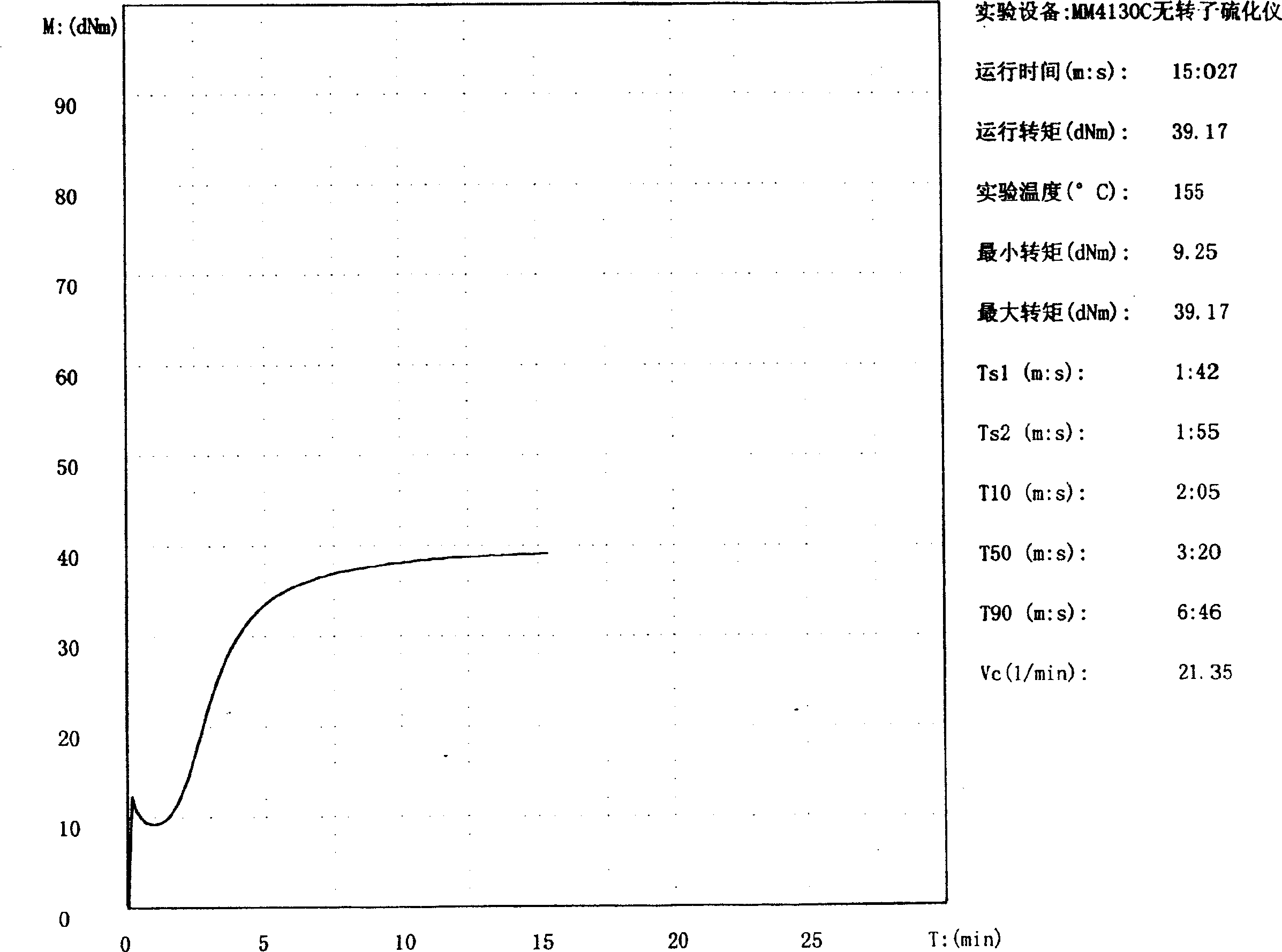

[0036] For the test report of its vulcanization meter, see figure 1 .

Embodiment 2

[0038] Natural rubber and chlorosulfonated polyethylene are used as rubber materials, and the proportioning is as follows in parts by weight:

[0039] Rubber 100, including: natural rubber SCR-5 85, chlorosulfonated polyethylene-40 15

[0040] Vulcanizing agent 3.7, including: sulfur 2.5, vulcanizing crosslinking agent 268 1.2

[0041] Accelerator 1.8, including: sulfenamide NOBS 1.5, sulfenamide CZ 0.3

[0042] Anti-aging agent 4.5, including: chemical anti-aging agent 4010NA 1.0, chemical anti-aging agent D

[0043] 1.5. Physical anti-aging agent - protective wax FLY-3 2

[0044] Reinforcing agent 52.0, including: reinforcing carbon black 42.0, white carbon black 10.0

[0045] Active agent 6.3, including: zinc oxide 5, stearic acid 1.3

[0046] Softening Plasticizer - Solid Coumarone 4.0.

[0047] serial number

[0048] 5

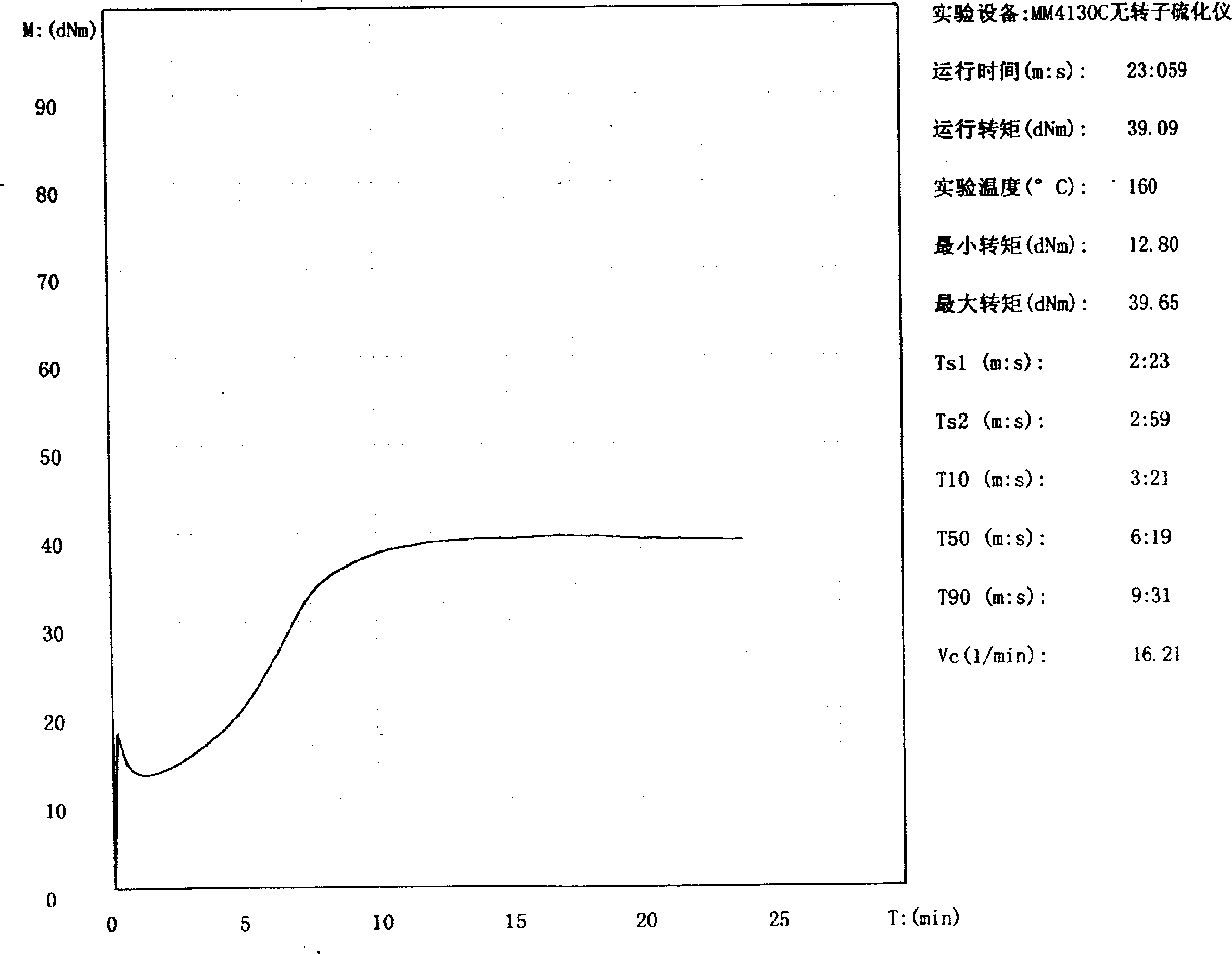

[0049] For the test report of its vulcanization meter, see figure 2 .

Embodiment 3

[0051] Natural rubber and chlorosulfonated polyethylene are used as rubber materials, and the proportioning is as follows in parts by weight:

[0052] Rubber 100, including: natural rubber SCR-5 85, chlorosulfonated polyethylene-40 15

[0053] Vulcanizing agent 3.7, including: sulfur 2.5, vulcanizing crosslinking agent 268 1.2

[0054] Accelerator 1.8, including: sulfenamide NOBS 1.5, sulfenamide CZ 0.3

[0055] Anti-aging agent 2.5, including: chemical anti-aging agent 4010NA 1.0, chemical anti-aging agent D 1.5

[0056] Reinforcing agent 59.0, including: reinforcing carbon black 49.0, white carbon black 10.0

[0057] Active agent 6.3, including: zinc oxide 5, stearic acid 1.3

[0058] Softening Plasticizer - Solid Coumarone 4.0

[0059] serial number

[0060] 6

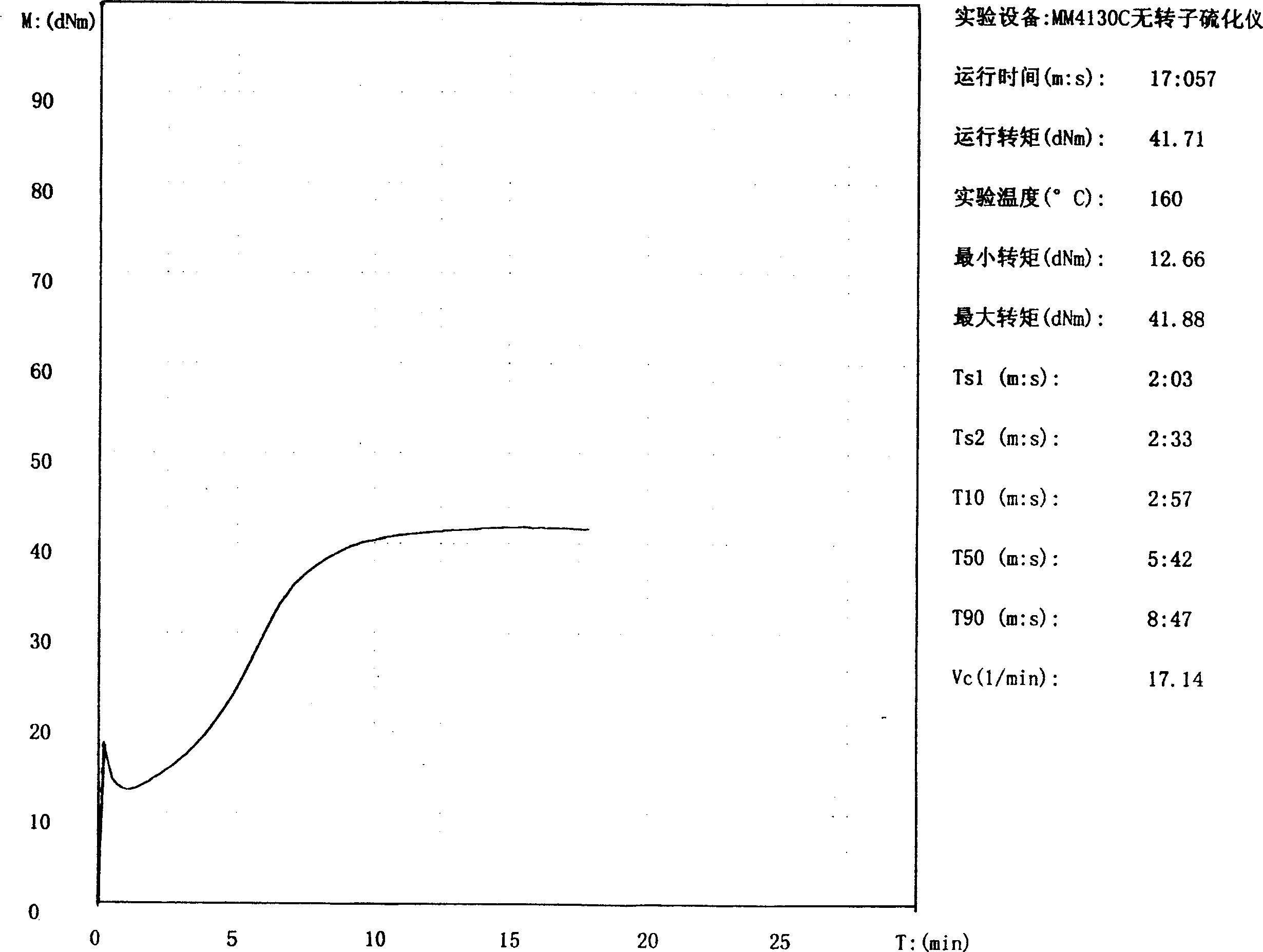

[0061] For the test report of its vulcanization meter, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com