Patents

Literature

50results about How to "Improved dynamic fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

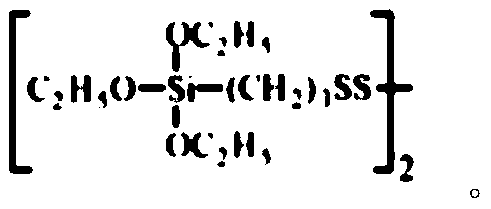

Abrasion and pierce proof low-resistance tire rubber compound and preparation method thereof

The invention discloses an abrasion and pierce proof low-resistance tire rubber compound and a preparation method thereof. The abrasion and pierce proof low-resistance tire rubber compound comprises, by weight, 40-70 parts of natural rubber SIR20, 10-15 parts of cis-polybutadiene rubber, 3-5 parts of styrene butadiene rubber SBR1500, 5-6 parts of N234 high-structure medium super abrasion furnace black, 5-6 parts of white carbon black, 1-1.5 parts of a silane coupling agent Si-69, 1-1.5 parts of polyethylene glycol, 0.5-1.0 part of toluene diisocyanate, 0.5-1.0 part of stannous chloride, 0.5-1.0 part of hydroxy-terminated polybutadiene, 1-1.5 parts of softening plasticizer aromatic oil, 1-2 parts of stearic acid, 2-3 parts of an antioxidant, 1-1.5 parts of tackifier 204 resin, 1-1.5 parts of a homogenizing agent UB4000, 0.5-1.0 part of zinc oxide, 1-1.5 parts of sulfur, 0.5-1.0 part of an XY900 anti-reversion agent, 1-1.5 parts of a promoter TBBS and 0.5-1.0 part of an anti-fatigue agent G-108. The tire rubber compound obtained in the invention has the advantages of good compatibility, abrasion proofing, pierce proofing, low resistance, fatigue proofing, ageing proofing, deformation proofing and wide application prospect.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

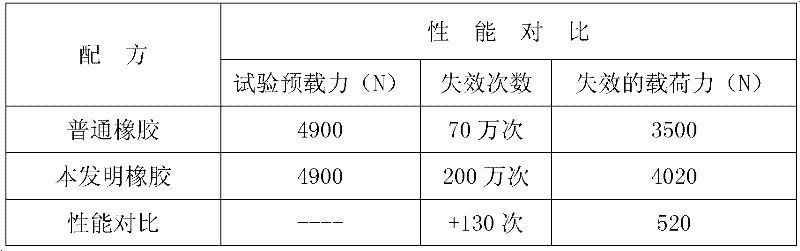

Rubber material for metal and rubber composite shock-absorbent product

The invention provides a rubber material for buffer composite with metal and rubber, comprising rubber, vulcanizing agent, accelerating agent, anti-aging agent, strengthening agent, active agent, elasticizer, filler and anticoking additive. The rubber material is characterized by good mechanical property, distinctive anti-aging property, strong adhesive strength between rubber and metal, permitted rubber creep range during usage, long coke burning time, and fast vulcanizing speed.

Owner:长春保卓轨道交通橡塑技术有限公司

High-strength synchronous belt and manufacturing method thereof

ActiveCN104675922AGood wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentCarbon blackPlasticizer

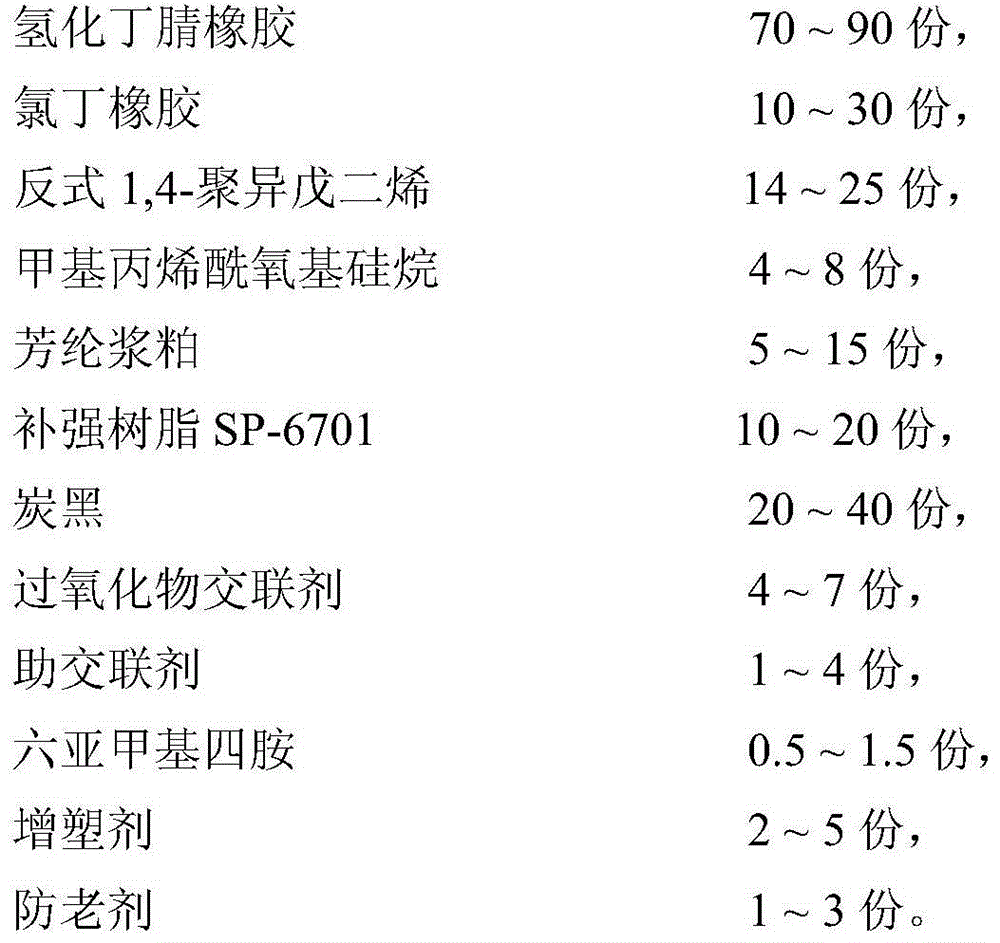

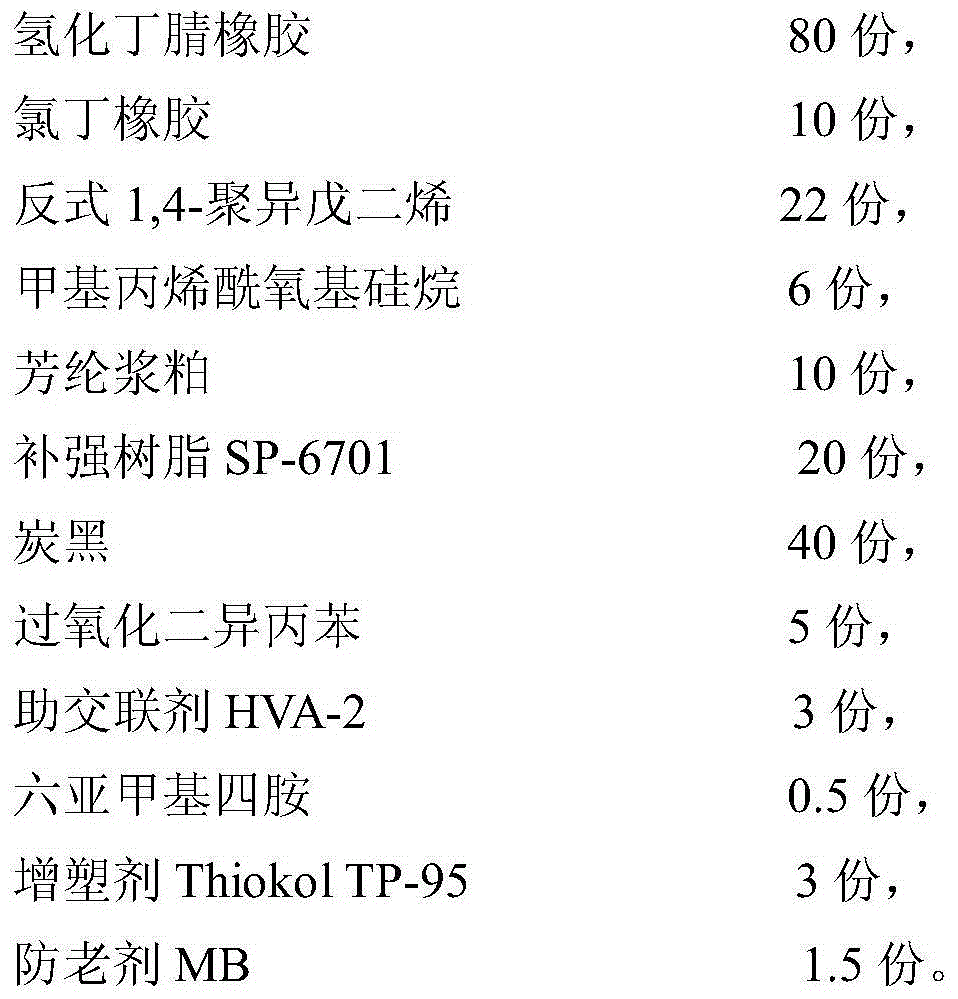

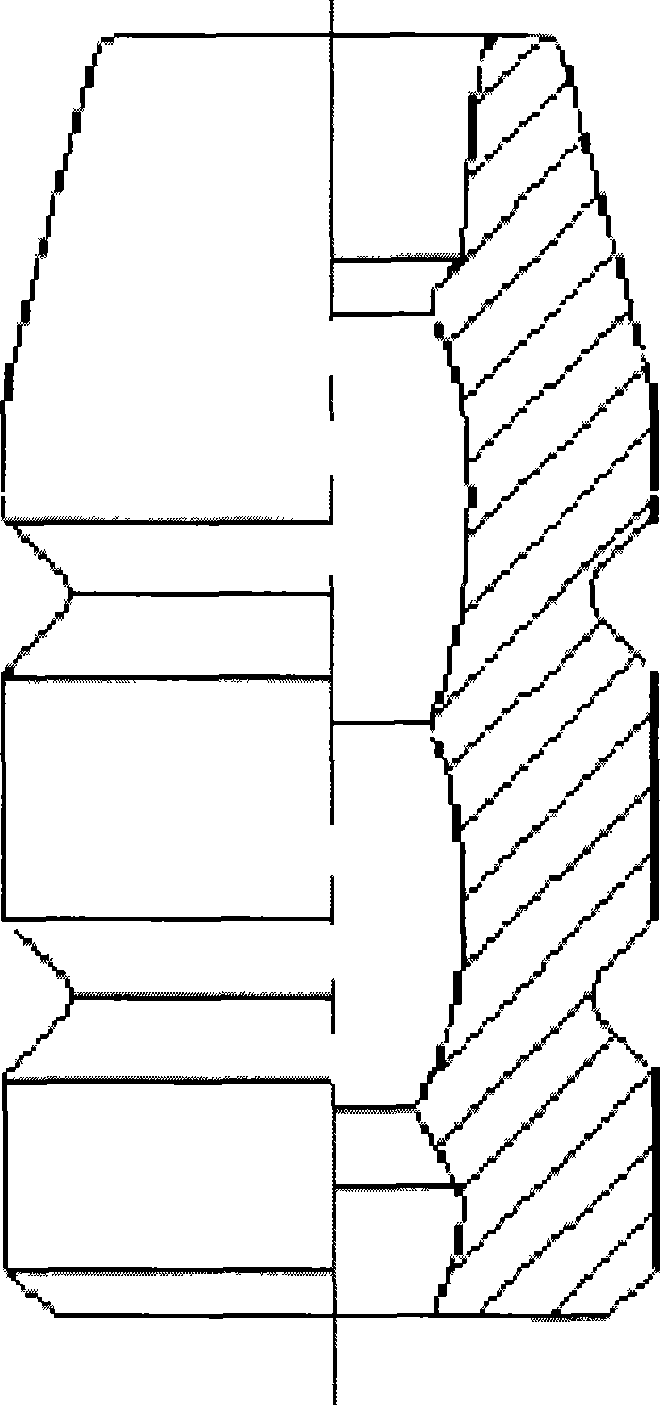

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

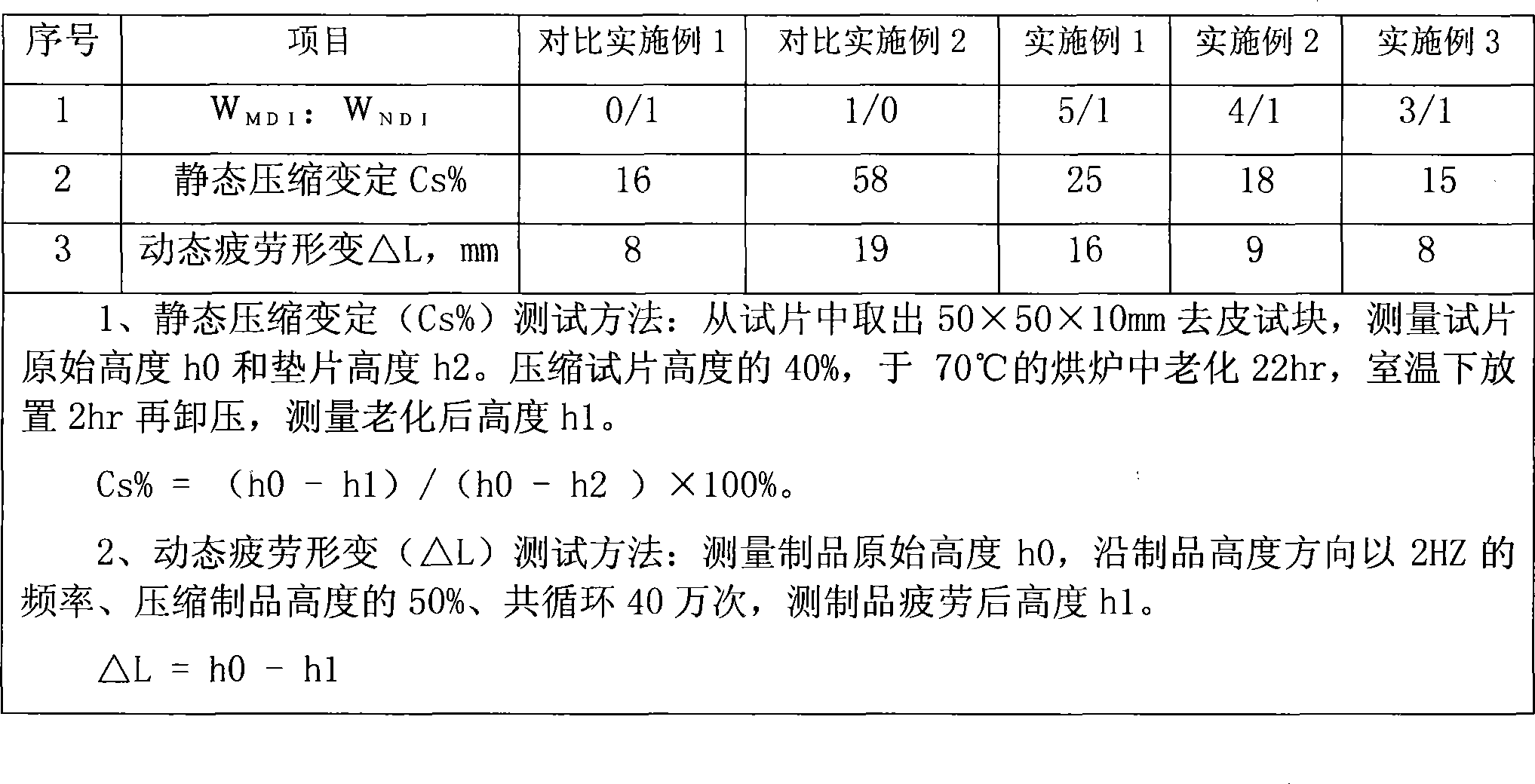

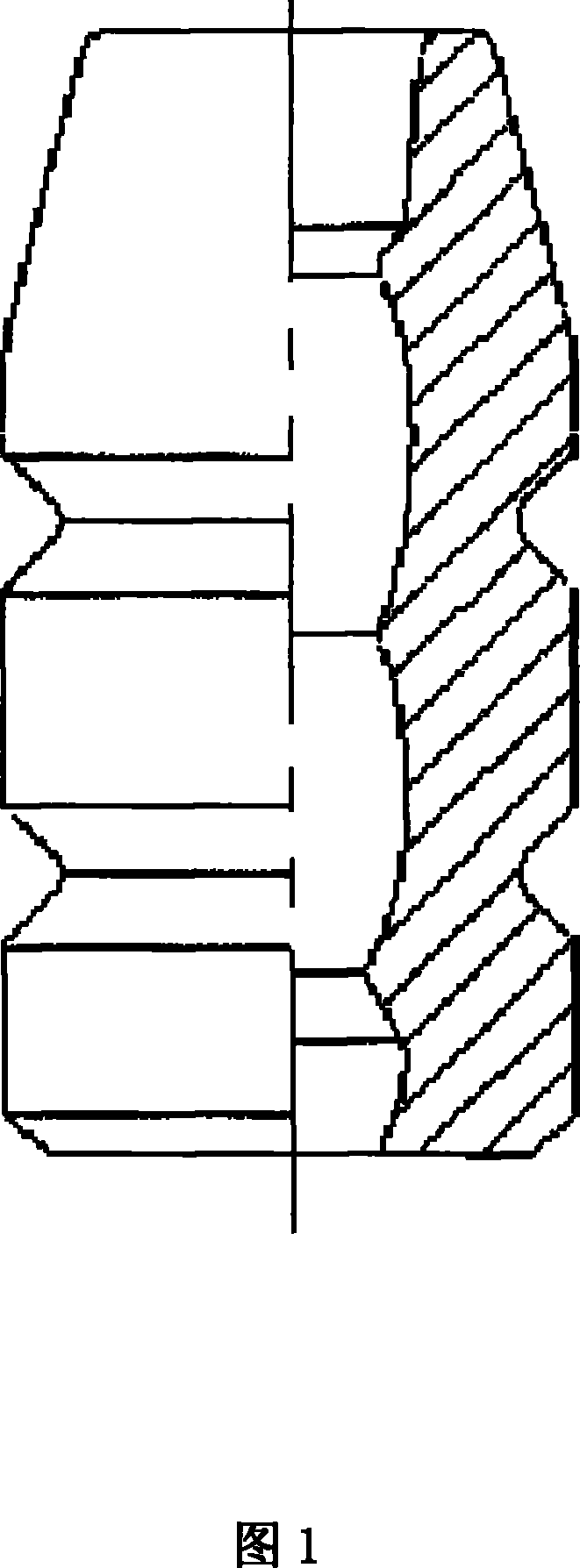

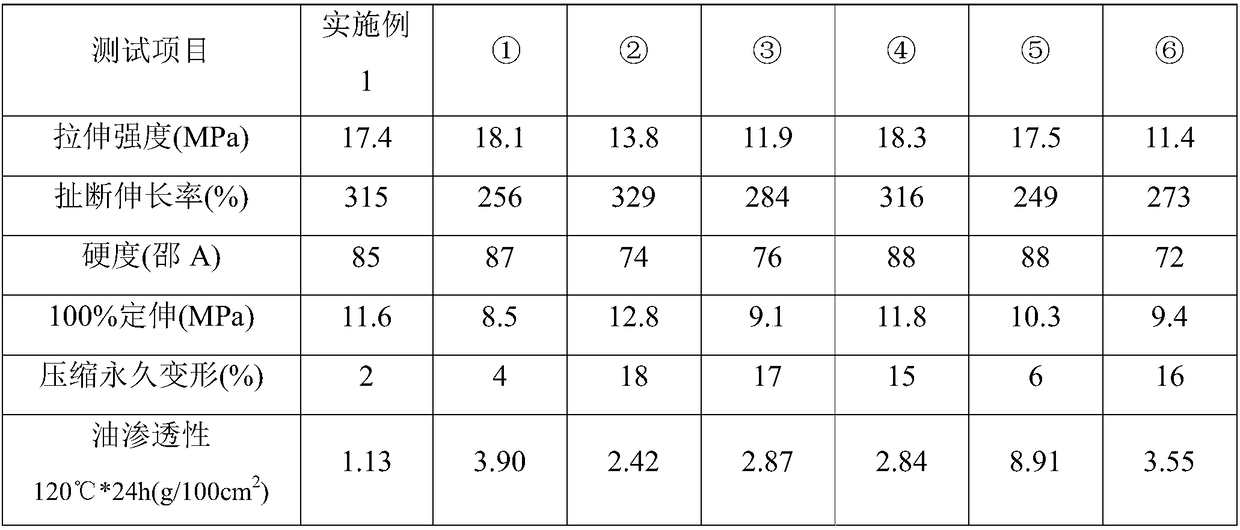

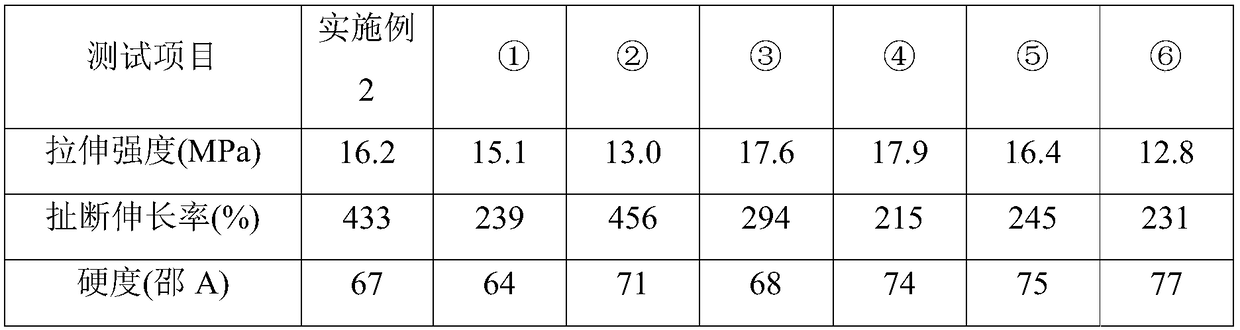

Method for producing NDI/MDI based polyurethane micropore elastomer

The invention discloses a preparation method for an MDI / NDI based polyurethane microporous elastomer, and aims to solve the problem of high fatigue deformation value of the polyurethane microporous elastomer in the prior MDI technology. The preparation method comprises the steps of preparation of prepolymer, and mixing, pouring and post curing of the prepolymer, and the like. A product prepared by the method is used as a high-intensity damping element for bearing dynamic fatigue, such as a damping element of a vehicle such as an automobile and the like, a bridge damping block, and the like, so as to optimize the dynamic fatigue property of the microporous elastomer by the MDI technology.

Owner:上海凯众材料科技股份有限公司

Rubber composition for dust prevention of vibration absorber

InactiveCN101372540AExtended service lifePerformance is not affectedRubber-like material springsLow internal friction springsPolymer scienceNitrile rubber

The invention provides a weather-resistant and anti-aging rubber composition for dust prevention of shock absorbers, which comprises 100 portions of nitrile butadiene rubber by weight, 45 portions of N220 carbon black by weight, 20 portions of N330 carbon black by weight, 20 portions of dioctyl by weight, 0.8-1 part of sulfur by weight, 0.8-1 part of dicumyl peroxide by weight, 2 portions of accelerator by weight, 1.8 portions of flowable agent by weight, 5 portions of zinc oxide by weight, 3.5-4.5 portions of anti-aging agent by weight and 2.5-3.2 portions of anti-cracking agent B10 by weight. The rubber composition solves the problems of poor quality of the former rubber products for the dust prevention of the shock absorbers used in auto-bikes and cars, no weather resistance and durability, low anti-fatigue flexibility and easy cracking, and the method has the advantages of more reasonable formula, better comprehensive properties with regards to elasticity, weather resistance, anti-aging and oil-proof properties. As a further improvement, 0.3 part of N, N'-diphenyl-para-phenylene diamine by weight is added to the components to more excellent ozone-resistant performance.

Owner:TAIZHOU CITY GANG YANG RUBBER

EPDM/EPM engine synthetic brake fluid and expansion resistance rubber material and manufacturing process thereof

The invention discloses an EPDM / EPM engine synthetic brake fluid and expansion resistance rubber material. The material is characterized in that the following components are proportionally mixed in parts by mass: 70-90 parts of EPDM (ethylene propylene diene monomer); 2-4 parts of zinc oxide; 1-3 parts of stearic acid SA; 2.5-4 parts of antiager BLE (liquid); 2-3.5 parts antiager SP (liquid) of 0.5-2 parts of antiager RD; 55-65 parts of N550 carbon black; 18-21 parts of EPM (binary ethylene propylene copolymer); 19-22 parts of StronWiNTC; 19-21 parts of liquid EPDM; 0.5-1.5 parts of assistant crosslinker IS; 1-2 parts of accelerant DM; 0.5-1.5 parts of crosslinker 96% peroxide vulcanizing agent DCP; 1.5-2.5 parts of polyethylene glycol; the invention further discloses a manufacturing process of the rubber material; the rubber material disclosed by the invention is high in quality and low in cost, does not expand in brake liquid, softener is not extracted, and volume expansion, solution, contraction and other phenomena of master and assistant cups are not caused.

Owner:ZHEJIANG KEDALI IND

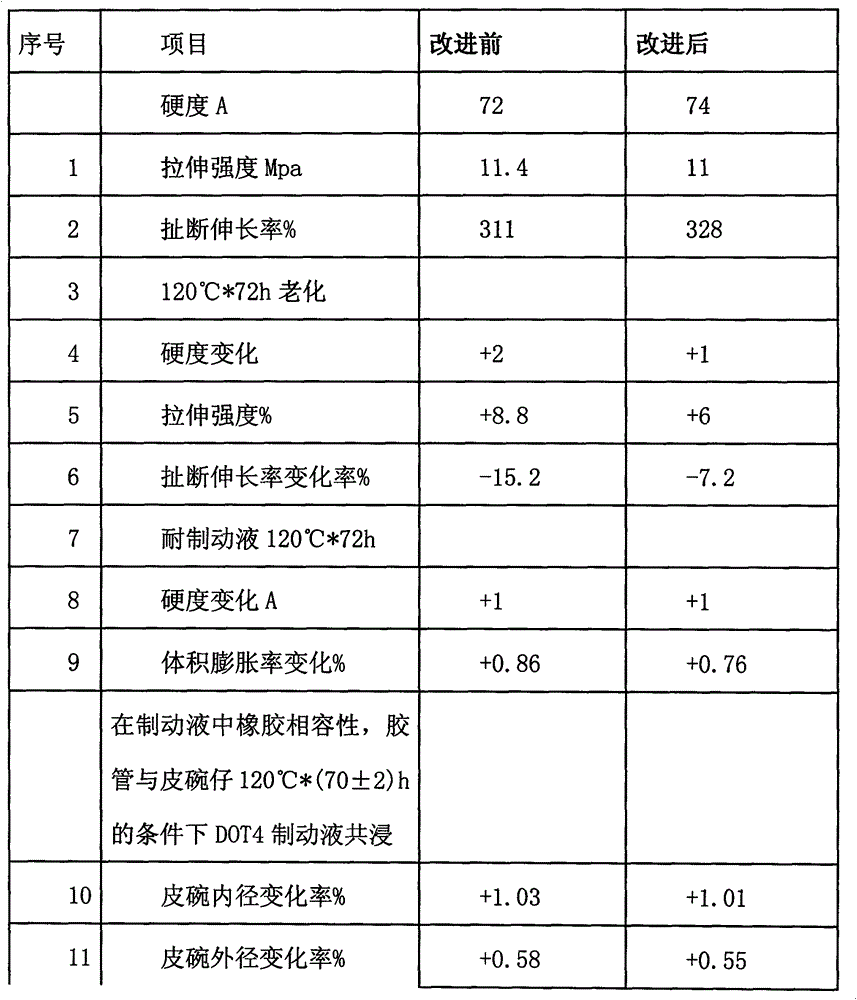

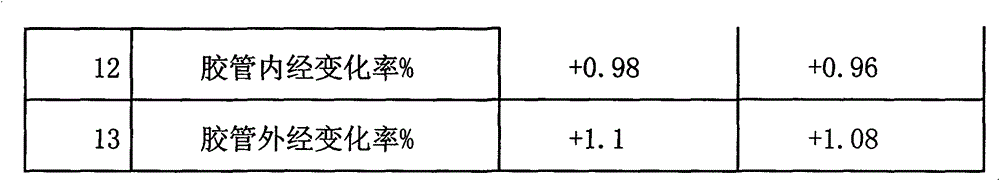

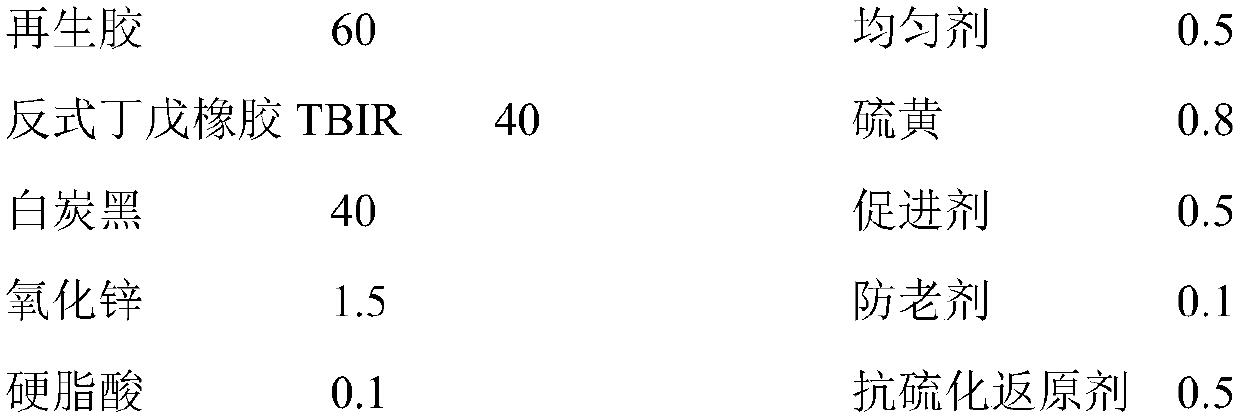

Trans-butadiene-isoprene rubber modified regenerated rubber as well as preparation method and purpose thereof

ActiveCN107814994AGuaranteed physical and mechanical propertiesImproved dynamic fatigue performanceSpecial tyresDispersityPolymer science

The invention relates to regenerated rubber modified by utilizing trans-butadiene-isoprene rubber as well as a preparation method and application thereof. The trans-butadiene-isoprene rubber modifiedregenerated rubber is prepared from the following components in parts by weight: 95 to 50 parts of regenerated rubber, 5 to 50 parts of the trans-butadiene-isoprene rubber TBIR, 2.5 to 50 parts of filling, 1.5 to 4 parts of zinc oxide, 0.1 to 0.6 part of stearic acid, 0 to 5 parts of homogenizing agent, 0.8 to 5 parts of sulfur, 0.5 to 3.5 parts of accelerant, 0.1 to 3 parts of anti-aging agent and 0 to 2.0 parts of anti-reversion agent. According to the preparation method, the regenerated rubber is modified by adopting the trans-butadiene-isoprene rubber TBIR; the dispersity of the filling can be improved; vulcanized rubber is increased by 30 to 70 percent in tensile strength, by 40 to 100 percent in 300-percent stress at definite elongation, by 10 to 20 percent in abrasion performance and by 100 to 700 percent in flexural fatigue performance. The regenerated rubber can be used for a tire tread, a tire side, a tire body, a belted layer and an airtight layer of a tire, a highway pavement and a runway and the dynamic fatigue performance is improved.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD +1

Carbon nano tube reinforcing epoxy structural adhesive and method for preparing same

InactiveCN102212322AImprove performanceHigh strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses carbon nano tube reinforcing epoxy structural adhesive and a method for preparing the same. The structural adhesive comprises a component A and a component B, and the weight ratio of the component A to the component B is 100:40.5-100:49.5, wherein the component A comprises the following raw materials in percentage by weight: 50 to 68 percent of epoxy resin, 1 to 10 percent of carbon nano tube epoxy resin reinforcing solution, 10 to 25 percent of thixotropic agent, 0.5 to 12.5 percent of additive and 2 to 10 percent of reaction thinner; and the component B comprises the following raw materials in percentage by weight: 90 to 95 percent of curing agent and 5 to 10 percent of thixotropic agent. The preparation method comprises the following steps of: mixing the component A and the component B, wherein the weight ratio of the component A to the component B ranges from 100:40.5 to 100:49.5; curing the mixture at the temperature of between 60 and 70 DEG C for 5 to 7 hours; and performing polyreaction to obtain the finished product.

Owner:YANTAI DARBOND TECH

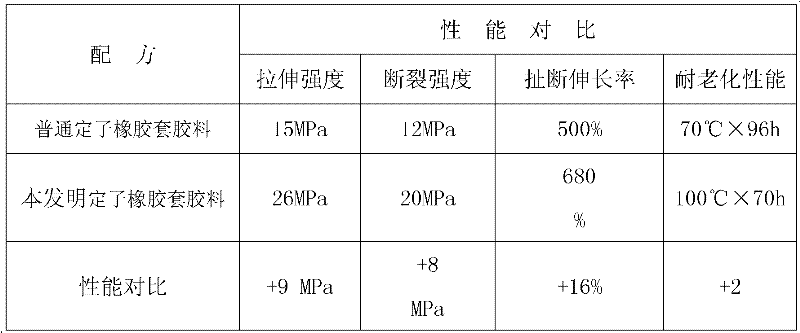

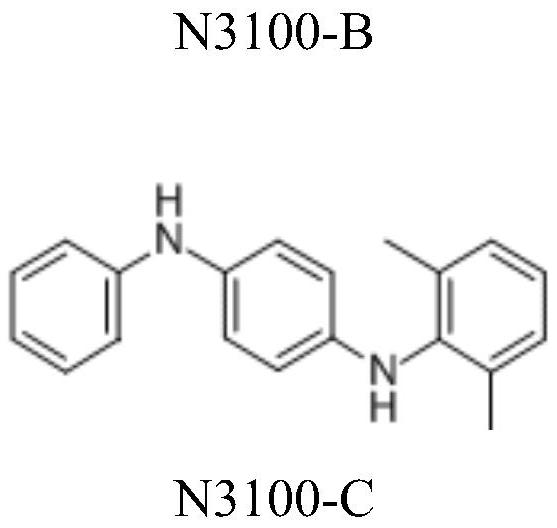

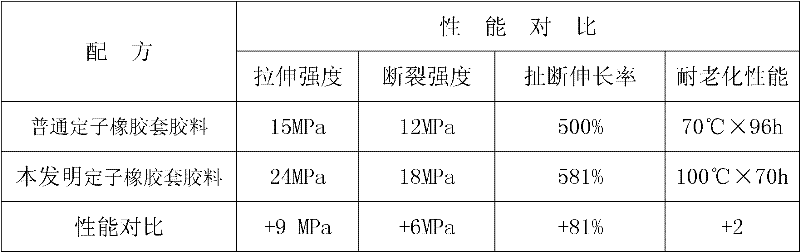

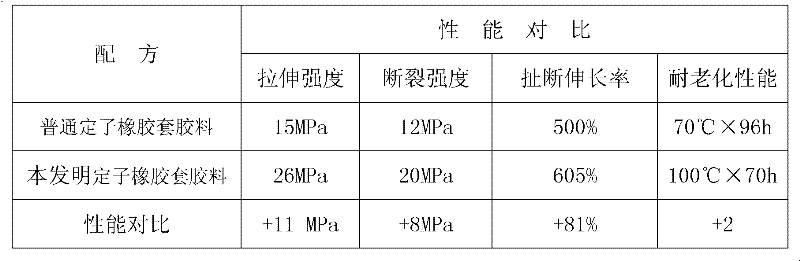

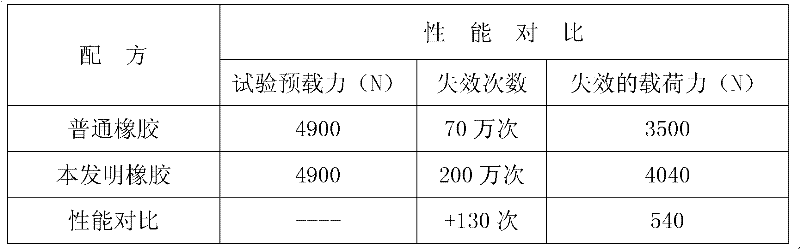

High-abrasion-resistance prestressed vacuum grouting pump stator rubber sleeve compound and preparation method thereof

The invention discloses a high-abrasion-resistance prestressed vacuum grouting pump stator rubber sleeve compound, which comprises the following constitutional raw materials in parts by weight: 85-90 parts of natural rubber, 0.5-0.7 parts of butyl rubber, 1.1-1.3 parts of silicon rubber PMQ, 4-6 parts of carboxyl nitrile rubber, 1.5-2.0 parts of methyl fluorosilicone rubber, 5-6 parts of butadiene rubber, 2-4 parts of zinc oxide, 0.3-0.5 parts of stearic acid, 0.3-0.6 parts of sulfur, 0.2-0.4 parts of anti-aging agent RDA, 8-12 parts of carbon black N660, 0.1-0.3 parts of accelerant, 3-5 parts of Antilux paraffin, 0.2-0.3 parts of anti-scorching agent CTP and 4-6 parts of cottonseed oil. During preparation, a part of formula raw materials are subjected to compound plasticization accordingto requirements, then other formula materials are added to perform compound mixing, and finally a vulcanization system is added to perform mill run for 5-7 times. A vacuum grouting pump stator rubbersleeve product produced by the rubber formula has excellent heat resistant aging performance and superior tear resistance performance and also has superior dynamic fatigue resistance performance.

Owner:HEFEI SHICHUAN ENG MACHINERY

Damping rubber composition

The invention discloses a damping rubber composition which comprises the following materials in parts by weight: 65-70 parts of graft modified natural rubber, 30-35 parts of chloroprene rubber, 3-5 parts of nano zinc oxide, 5-8 parts of anti-ageing agent, 4-6 parts of stearic acid, 25-44 parts of high abrasion furnace black, 10-20 parts of organic modified rectorite, 5-10 parts of organic modified white carbon black, 7-9 parts of plasticizer, 1-1.5 parts of vulcanizing agent and 1-2 parts of accelerant. The damping rubber composition disclosed by the invention is good in impact resistance and good in vibrating absorption, and can be used as damping materials in the fields such as mechanical equipment, cars, and the like.

Owner:安徽宁国尚鼎橡塑制品有限公司

Special wear-resisting rubber composite

The invention provides a special wear-resisting rubber composite, which comprises the following components in part by weight: 105 parts of nitrile butadiene rubber, 55 parts of N220 carbon black, 15 parts of N330 carbon black, 30 parts of dioctyl phthalate, 0.8 to 1 part of sulfur, 0.8 to 1 part of dicumyl peroxide, 2 parts of accelerator, 2.1 parts of flowable agent, 5 parts of zinc oxide, 3.5 to 4.5 parts of antioxidant and 4 to 5.2 parts of cracking inhibitor. As further improvement, 0.5 part of N,N'-diphenyl-phenylene diamine is added into the components, so that the special abrasive rubber composite has better ozone resistance. The special wear-resisting rubber composite is characterized by more reasonable formula and excellent combination property of elasticity, weatherability, ageing resistance and oil resistance.

Owner:夏永宽

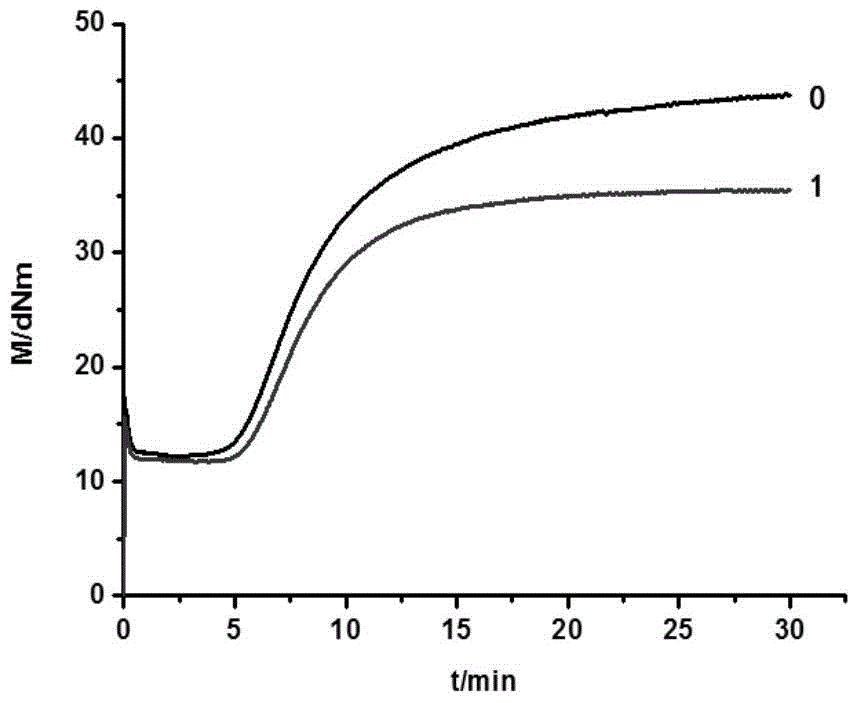

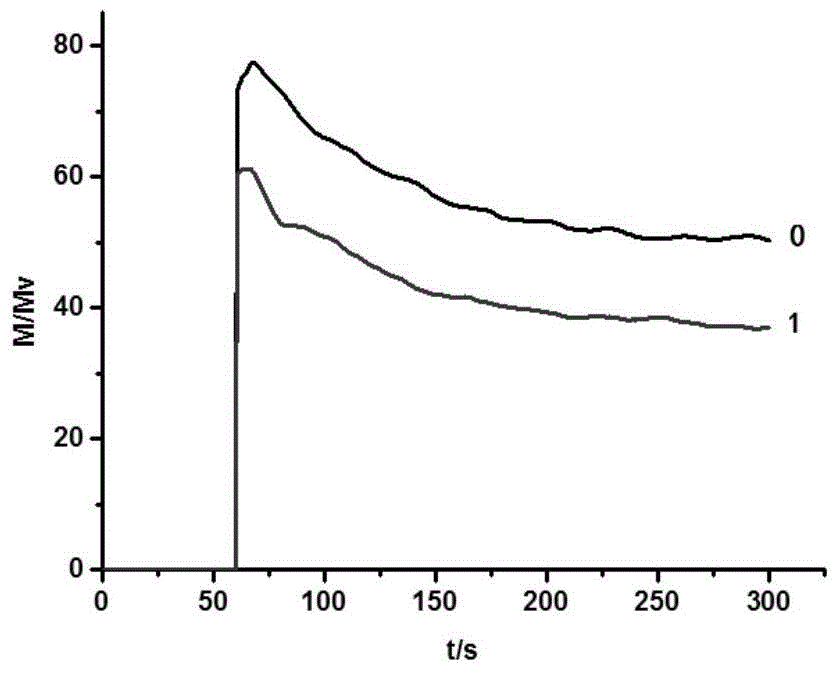

Bio-based reinforced plasticiser-eucommia ulmoides resin and preparation method thereof

The invention discloses a bio-based reinforced plasticiser-eucommia ulmoides resin and a preparation method thereof, and bio-based reinforced plasticiser-eucommia ulmoides resin and the preparation method thereof are applied to the field of rubber industry plasticisers. Traditional rubber plasticisers all come from fossil resources, belong to non-renewable materials and can deteriorate the mechanical property of rubber. The eucommia ulmoides resin can improve the processing property of the rubber and reduce energy consumption, also can improve the mechanical property of the rubber and overcome the defect that the traditional plasticisers achieve plastification and do not achieve reinforcement and is a novel, renewable, green and environment-friendly bio-based reinforced plasticiser. A rubber material modified by the eucommia ulmoides resin has the advantages that the Mooney viscosity is reduced, the vulcanizing time is shortened, the tensile strength and the tear strength are improved, the elongation at break is increased, and the dynamic fatigue property is improved. The eucommia ulmoides resin is an important composing part of comprehensive development of eucommia ulmoides gum, can enable by-products obtained through eucommia ulmoides gum production to be effectively utilized and has the advantages that the raw material utilization efficiency is improved, waste materials are changed into things of value, the environment is protected, the production process is simple and convenient, the production cost of the eucommia ulmoides gum is lowered, and the economic benefit and the social benefit are significant.

Owner:BEIJING UNIV OF CHEM TECH

Preparation material of scratch-resistant screen wiper rubber sheet and preparation method thereof

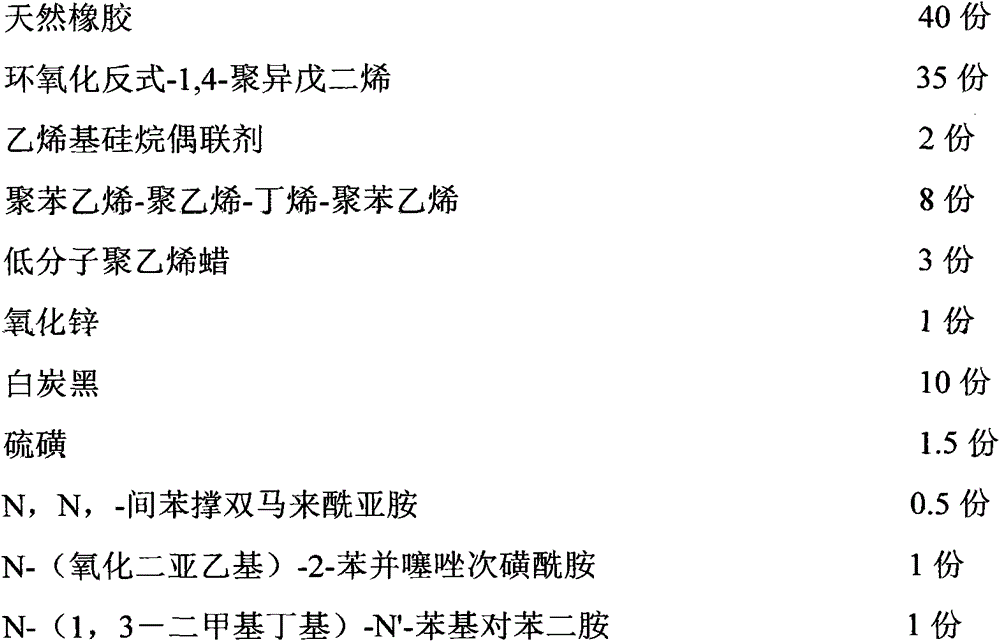

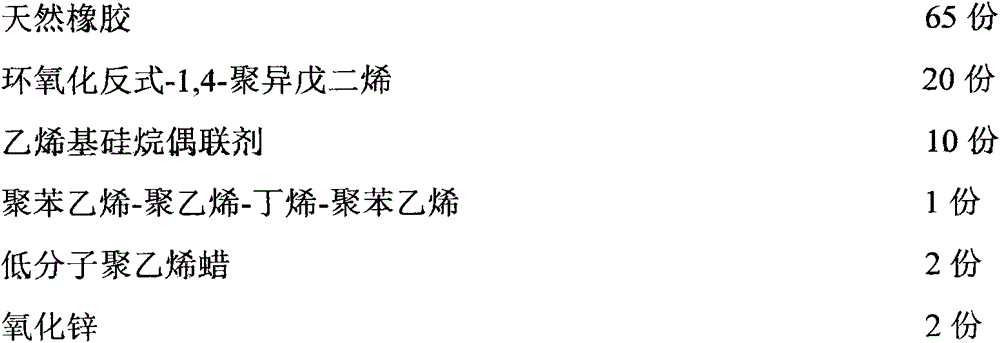

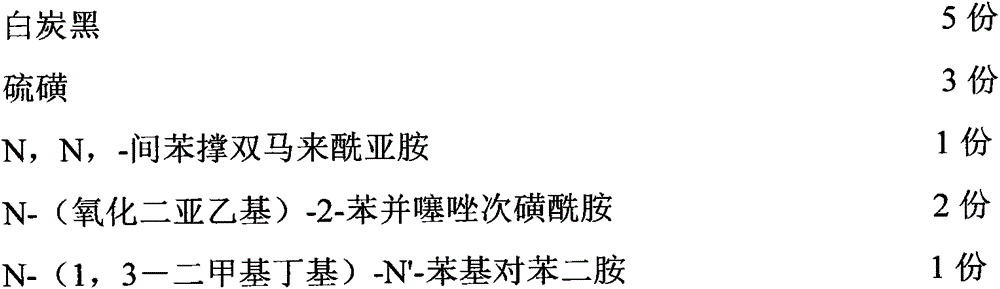

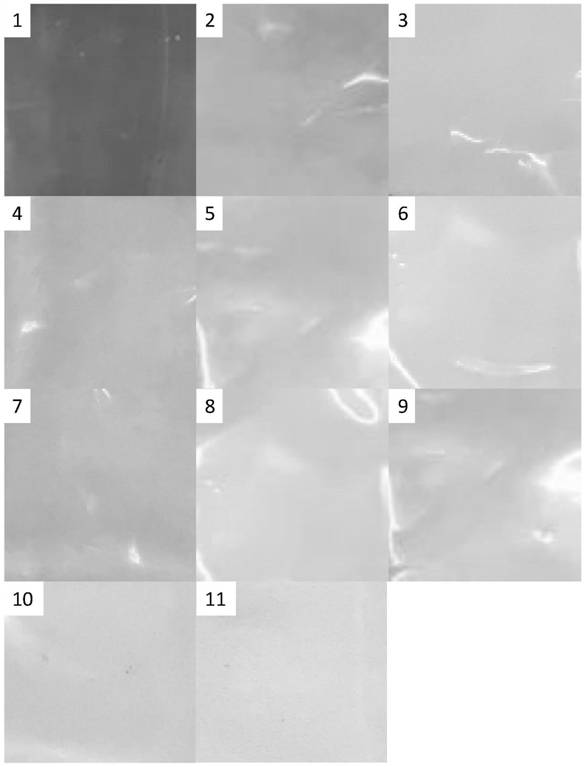

The invention discloses a preparation material of a scratch-resistant screen wiper rubber sheet, which is prepared from the following components in parts by weight: 40-90 parts of natural rubber, 20-50 parts of epoxidated trans-1,4-polyisoprene, 2-10 parts of vinyl silane coupling agent, 1-8 parts of polystyrene-polyethylene-butylene-polystyrene, 1-3 parts of processing assistant, 1-3 parts of zinc oxide, 5-20 parts of silica white, 2-5 parts of vulcanizing agent, 1-3 parts of vulcanization accelerator and 1-2 parts of anti-aging agent. The screen wiper rubber sheet prepared by the preparation material and preparation method has the characteristics of long service life and favorable wiping effect.

Owner:宁波汉德汽车配件有限公司

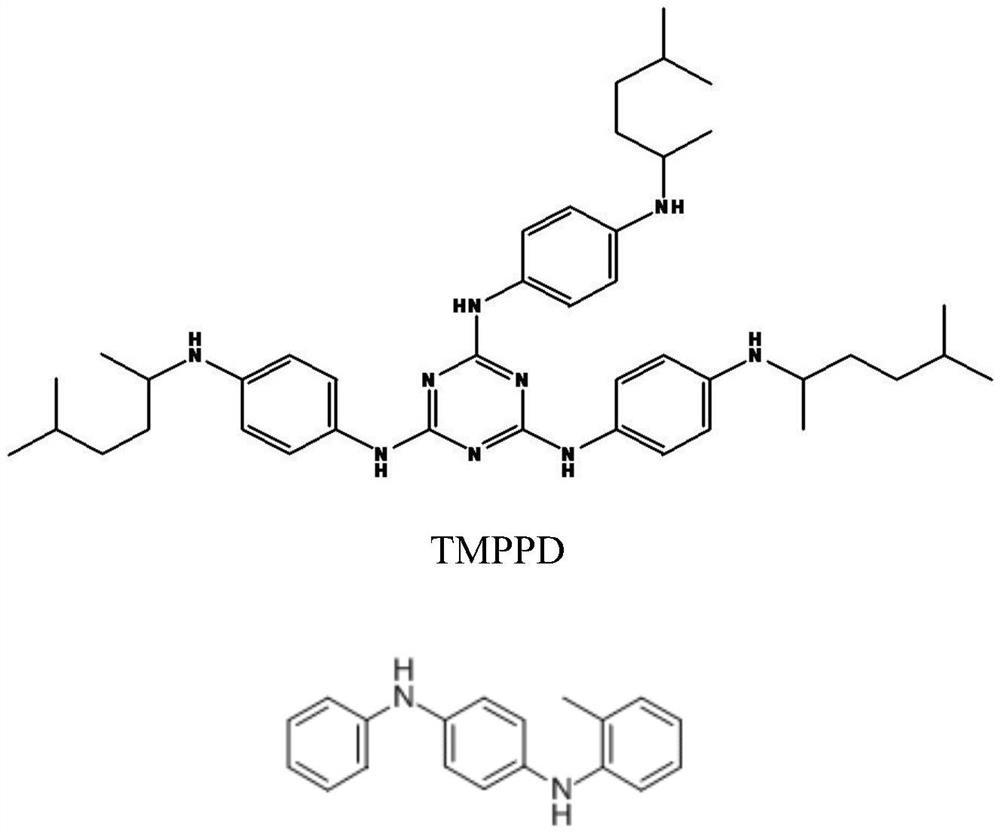

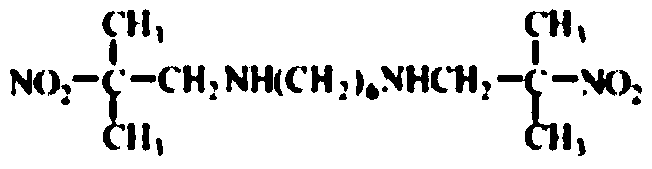

Anti-aging agent composition, anti-aging agent masterbatch and rubber composition

The invention provides an anti-aging agent composition, an anti-aging agent masterbatch containing the anti-aging agent composition, and a rubber composition containing the anti-aging agent composition or the anti-aging agent masterbatch. The anti-aging agent composition contains an anti-aging agent TMPPD and one or two selected from the group consisting of an anti-aging agent N3100-B and an anti-aging agent N3100-C. According to the anti-aging agent composition and the anti-aging agent masterbatch disclosed by the invention, the rubber composition and a rubber product can have excellent anti-discoloration performance, excellent fatigue resistance, excellent ozone resistance and excellent mechanical properties before aging and after thermo-oxidative aging at the same time, so that the rubber composition and the rubber product can be used for manufacturing all or part of rubber matrixes of tires, and particularly, the rubber composition is used as a tire sidewall rubber composition anda tread rubber composition.

Owner:JIANGSU SINORGCHEM TECH CO LTD

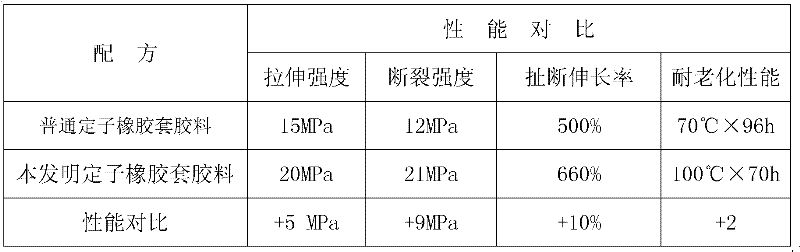

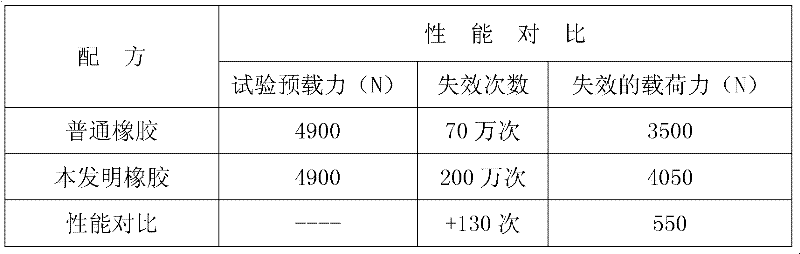

Sizing material of stator rubber sleeve for pre-stressed vacuum grouting pump and preparation method thereof

The invention discloses a sizing material of a stator rubber sleeve for a pre-stressed vacuum grouting pump. The sizing material comprises the following raw materials by weight: 95 to 105 parts of natural rubber, 4 to 6 parts of isoprene rubber, 0.04 to 0.06 parts of butadiene rubber, 1.1 to 1.3 parts of styrene-butadiene rubber, 2 to 4 parts of zinc oxide, 0.3 to 0.5 parts of stearic acid, 0.3 to 0.6 parts of sulfur, 0.2 to 0.4 parts of antiagers DPPD (Diphenyl-P-Phenylene Diamine), 8 to 12 parts of carbon black N339, 0.1 to 0.3 parts of accelerating agents M, 3 to 5 parts of Rhine wax, 0.2 to 0.3 parts of antiscorcher CTP (cytidine triphosphate), and 4 to 6 parts of cottonseed oil. When the sizing material is prepared, a part of formula raw materials is processed through sizing materialplastication at first as required, then other formula materials are added for sizing material mixing, and a vulcanization system is added and is processed through thin-passing for 5 to 7 times finally. Rubber damping products that are produced according to the rubber formula achieve favorable heat-proof aging performance and excellent tear resistance, and also achieve excellent dynamic fatigue resisting performance.

Owner:HEFEI SHICHUAN ENG MACHINERY

Rubber material for stator rubber sleeve of prestressed vacuum grout pump and preparation method thereof

The invention discloses a rubber material for a stator rubber sleeve of a prestressed vacuum grout pump. The rubber material comprises the following raw materials in parts by weight: 95-105 parts of natural rubber, 4-6 parts of isoprene rubber, 0.04-0.06 part of butadiene rubber, 1.1-1.3 parts of styrene butadiene rubber, 2-4 parts of zinc oxide, 0.3-0.5 part of stearic acid, 0.3-0.6 part of sulfur, 0.2-0.4 part of antioxidant DPPD, 8-12 parts of carbon black N339, 0.1-0.3 part of accelerator M, 3-5 parts of Rhine wax, 0.2-0.3 part of scorch retarder CTP and 4-6 parts of cottonseed oil. A preparation method comprises the following steps: firstly plasticating a part of raw materials in the formula as required, then adding the other materials for carrying out mixing of rubber material and finally adding a vulcanization system and carrying out thin-passing 5-7 times. The rubber damping products produced according to the rubber formula have good heat aging resistance, excellent tear resistance and excellent dynamic fatigue resistance.

Owner:HEFEI SHICHUAN ENG MACHINERY

Anti-tear silicone rubber compound and preparation method thereof

The invention discloses an anti-tear silicone rubber compound and a preparation method thereof, and belongs to the field of chemical industry. According to a silicone rubber base material for preparation, fluorine-containing siloxane is added in a mixed rubber base material, so that oil resistance of the silicone rubber is improved, and advantage combination of the silicone rubber and a mixed rubber additive are increased. Mixed rubber filler for preparation is prepared by taking white carbon black and nano carbon tubes as raw materials, so that temperature resistance of the rubber compound isimproved, and bonding performance between the rubber compound and a the silicone rubber matrix is improved. A cross-linking additive for preparation is prepared by taking lac and fumaric acid as rawmaterials, and has relatively good tear resistance and tensile strength. Aramid fiber short fibers and aramid fiber pulp are added, so that cross-linking activity in a mixing process is improved. According to the invention, the silicone rubber base material is added to improve oil resistance, and mixed fibers are added in the mixing process, so that various properties of the rubber compound are well combined. According to the invention, the problems of poor oil resistance and poor tear resistance of existing silicone rubber are solved.

Owner:黄广展

Easy-to-produce and highly corrosion-resistant valve rubber composition

The invention is an easy-to-produce and highly corrosion-resistant valve rubber composition, which is made of the following materials in weight percent: 52-55 parts by weight of 60 / 40 EPDM rubber, 3-5 parts by weight of active zinc oxide, 0.5-0.7 parts by weight of organic active agent stearic acid, 13-18 parts by weight of N220 carbon black, 18-22 parts by weight of N330 carbon black, 1-3 parts by weight of dimethyl phthalate, and 1-2 parts by weight of dispersant , 0.8 to 1 parts by weight of sulfur, 0.4 to 0.6 parts by weight of dicumyl peroxide, 2 parts by weight of accelerator, 2.1 parts by weight of flow agent, 5 parts by weight of zinc oxide, 3.5 to 4.5 parts by weight of antioxidant, 9 parts by weight of liquid softener ~12 parts by weight, 0.8~1.2 parts by weight of N,N'-diphenyl-p-phenylenediamine, 4~5.2 parts by weight of crack preventing agent, and 1~3 parts by weight of 2% water-emulsified silicone mold release agent. The invention is characterized in that the formula is more reasonable, the prepared rubber composition is easy to demould during production, the overall appearance is good, and it is highly corrosion-resistant.

Owner:江苏江华阀业有限公司

Rubber shock absorber and preparation method thereof

The invention discloses a rubber shock absorber. The rubber shock absorber is prepared from the components in parts: 60-75 parts of butyl rubber, 30-55 parts of natural rubber, 10-19 parts of ingredient rubber, 25-45 parts of filler, 6-8 parts of mineral fiber, 1-2 parts of vulcanizing agent, 0.2-0.6 part of stearic acid, 3-7 parts of paraffin wax, 1-5 parts of aluminum-zirconium coupling agents,2-4 parts of polyethylene glycol stearate, 0.5-1.5 parts of crosslinkers, 1-2 parts of antioxidants,1-3 parts of accelerators, 3-5 parts of magnesium oxide and 3-7 parts of magnesium oxide.

Owner:ANHUI DFSEAL RUBBER SHOCK ABSORBER TECH CO LTD

Polyurethane microporous elastic body production method

InactiveCN1314723CGood physical and mechanical propertiesHigh strengthPolyurethane elastomerHigh intensity

A process for preparing the millipore polyurethane elastomer used for high-strength damping elements includes proportionally mixing prepolymer at 35-60 deg.C with polyol resin, adding delay alamine as catalyst, reaction, pouring in mould at 50-70 deg.C and ageing.

Owner:上海凯众聚氨酯有限公司

Formula and preparation method of all-steel tire carcass

InactiveCN110157056AReduce the leakage phenomenonImprove driving safetySpecial tyresSulfurCobalt salt

The invention belongs to the technical field of tire formulas, and concretely relates to a formula and a preparation method of an all-steel tire carcass. The formula comprises, by mass, 70-95 parts ofnatural rubber, 5-30 parts of a trans-isoprene-butadiene copolymer, 50-60 parts of carbon black, 0.5-1.5 parts of a cobalt salt, 4-5 parts of ZnO, 0-2 parts of stearic acid, 2-3 parts of an antioxidant, 2-4 parts of insoluble sulfur, 1-2 parts of a promoter and 0.2-0.5 part of an anti-scorching agent CTP. The invention can improve the dynamic fatigue performance of the carcass formula and prolongthe service life of tires, and the high modulus caused by crystallization of the formula at normal temperature can effectively reduce exposed cords in tire cavities, caused by stretching during tiremolding, and improves the qualified rate of the product.

Owner:JIANGSU GENERAL SCI TECH

Prestressed vacuum grouting pump screw stator sleeve rubber compound and preparation method thereof

The invention discloses a prestressed vacuum grouting pump screw stator sleeve rubber compound, which comprises the following constitutional raw materials in parts by weight: 85-90 parts of natural rubber, 0.5-0.7 parts of butyl rubber, 1.1-1.3 parts of silicon rubber VMQ, 4-6 parts of carboxyl nitrile rubber, 1.5-2.0 parts of methyl fluorosilicone rubber, 2-4 parts of zinc oxide, 0.4-0.6 parts of magnesium oxide, 0.3-0.5 parts of stearic acid, 0.3-0.6 parts of sulfur, 0.2-0.4 parts of anti-aging agent DPPD (Diphenyl-Phenylene-Diamine), 8-12 parts of carbon black N339, 0.1-0.3 parts of accelerant NOBS, 3-5 parts of paraffin, 0.2-0.3 parts of anti-scorching agent CTP and 4-6 parts of soybean oil. During preparation, a part of formula raw materials are subjected to compound plasticization according to requirements, then other formula materials are added to perform compound mixing, and finally a vulcanization system is added to perform mill run for 5-7 times. A prestressed vacuum grouting pump screw stator sleeve product produced by the rubber formula has excellent heat resistant aging performance and superior tear resistance performance and also has superior dynamic fatigue resistance performance.

Owner:HEFEI SHICHUAN ENG MACHINERY

Method for producing NDI/MDI based polyurethane micropore elastomer

The invention discloses a preparation method for an MDI / NDI based polyurethane microporous elastomer, and aims to solve the problem of high fatigue deformation value of the polyurethane microporous elastomer in the prior MDI technology. The preparation method comprises the steps of preparation of prepolymer, and mixing, pouring and post curing of the prepolymer, and the like. A product prepared by the method is used as a high-intensity damping element for bearing dynamic fatigue, such as a damping element of a vehicle such as an automobile and the like, a bridge damping block, and the like, so as to optimize the dynamic fatigue property of the microporous elastomer by the MDI technology.

Owner:上海凯众材料科技股份有限公司

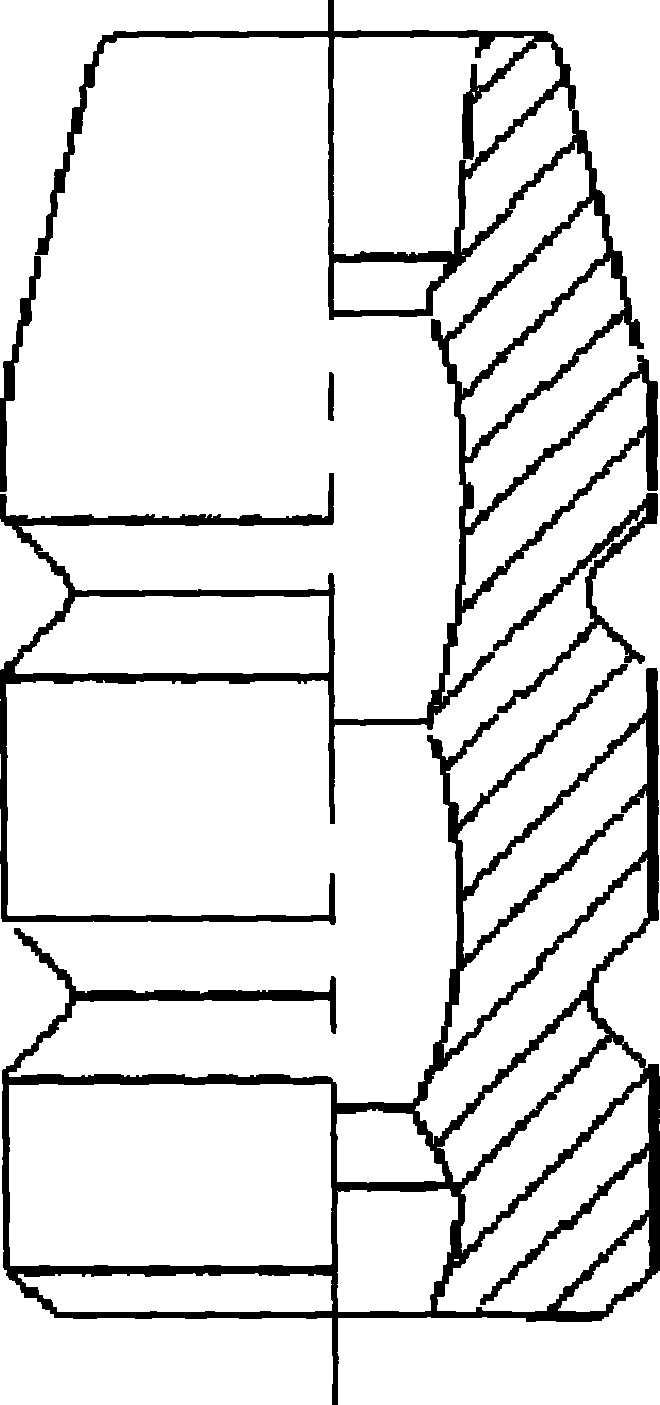

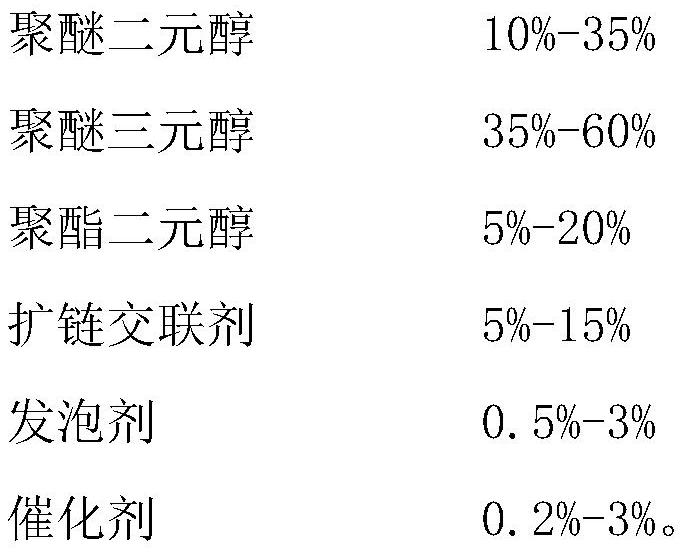

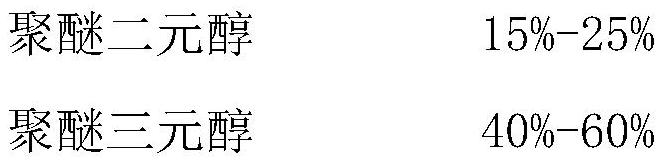

Polyurethane microporous elastomer and sole material and damping material applying elastomer

The invention belongs to the technical field of polymer synthetic materials, and particularly relates to a polyurethane microporous elastomer with the density of 0.5 g / cm < 3 >-0.8 g / cm < 3 >, the hardness of 35 Shore D to 55 Shore D, the tensile strength of 1 MPa to 3 MPa, the elongation at break of 200% to 500% and the abrasion loss of 100 mm < 3 >-250 mm < 3 >. The polyurethane microporous elastomer is prepared from an isocyanate component and an isocyanate reactive component through a reaction, the molar ratio of an isocyanate group in the isocyanate component to a hydroxyl group in the isocyanate reactive component is 1: (1-2.4). The polyether polyol and the polyester polyol are combined to serve as reaction raw materials, the effects of improving the flexibility of the polyurethane microporous elastomer and prolonging the elongation at break, the tensile strength, the tearing strength and the deformation resistance can be achieved, and the hydrolysis resistance of the polyurethane microporous elastomer can be effectively improved. In addition, the invention also provides a sole material using the elastomer, and a damping material using the elastomer.

Owner:广东粤港澳大湾区黄埔材料研究院

Rubber compositions for highly corrosive valves

InactiveCN102276929AIncrease elasticityExcellent resistance to flex crackingActive agentStearic acid

A rubber composition for highly corrosive valves of the present invention is made of the following materials in weight percent: 52-55 parts by weight of 60 / 40 EPDM rubber, 3-5 parts by weight of active zinc oxide, organic active agent 0.5-0.7 parts by weight of stearic acid, 13-18 parts by weight of N220 carbon black, 18-22 parts by weight of N330 carbon black, 5-6 parts by weight of silicon nitrogen compound, 1-3 parts by weight of dimethyl phthalate, dispersed 1-2 parts by weight of agent, 0.8-1 parts by weight of sulfur, 0.4-0.6 parts by weight of dicumyl peroxide, 2 parts by weight of accelerator, 2.1 parts by weight of flow agent, 5 parts by weight of zinc oxide, 3.5-4.5 parts by weight of anti-aging agent 9-12 parts by weight of liquid softener, 6-8 parts by weight of linseed oil, and 0.8-1.2 parts by weight of N,N'-diphenyl-p-phenylenediamine. The invention is characterized in that the formula is more reasonable, the prepared rubber composition has good elasticity and toughness, and is safer and more reliable when used in high-corrosion valves.

Owner:JIANGSU JIANGHUA VALVE IND CO LTD

Outer layer rubber for high-temperature resistance flexible rubber hose

ActiveCN109337349AImprove corrosion resistanceReduce wear loss and compression fatigue temperature riseFlexible pipesMicaCarbon black

The invention discloses outer layer rubber for a high-temperature resistance flexible rubber hose. The outer layer rubber is prepared from the following components in parts by weight: 35 parts of rubber material Ethylene-Propylene-Diene Monomer (EPDM), 65 parts of polyurethane elastomer rubber TPU, 9 parts of mica powder, 55 parts of carbon black, 2.1 parts of stearic acid, 4.5 parts of a plasticizer, 1.3 parts of a promoter DM, 0.8 part of a vulcanizing agent DCP, 0.76 part of sulphur, 5.0 parts of an ant-ageing agent AW, and 0.7 part of a composite flame retardant FR201. The invention further discloses a high-temperature resistance flexible rubber hose. The outer layer rubber material prepared by the invention is very good in fluidity, so that the hose can be softened to be to coil, hasvery good affinity with a middle rubber layer, and is difficult to fracture and good in wear resistance, and scratch resistance of the hose is greatly improved.

Owner:LUOHE BONWELL RUBBER

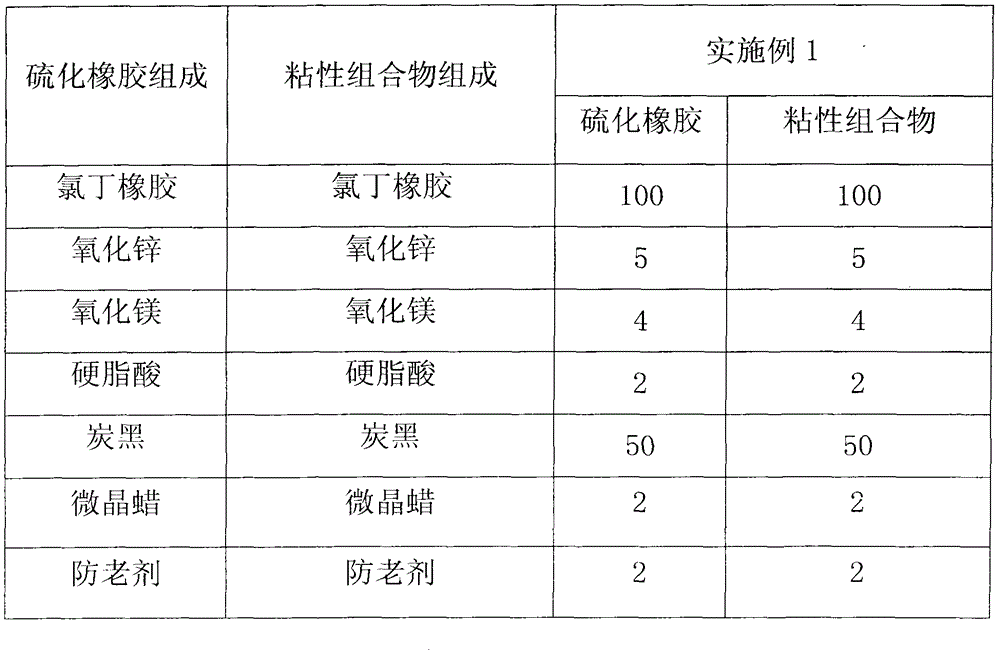

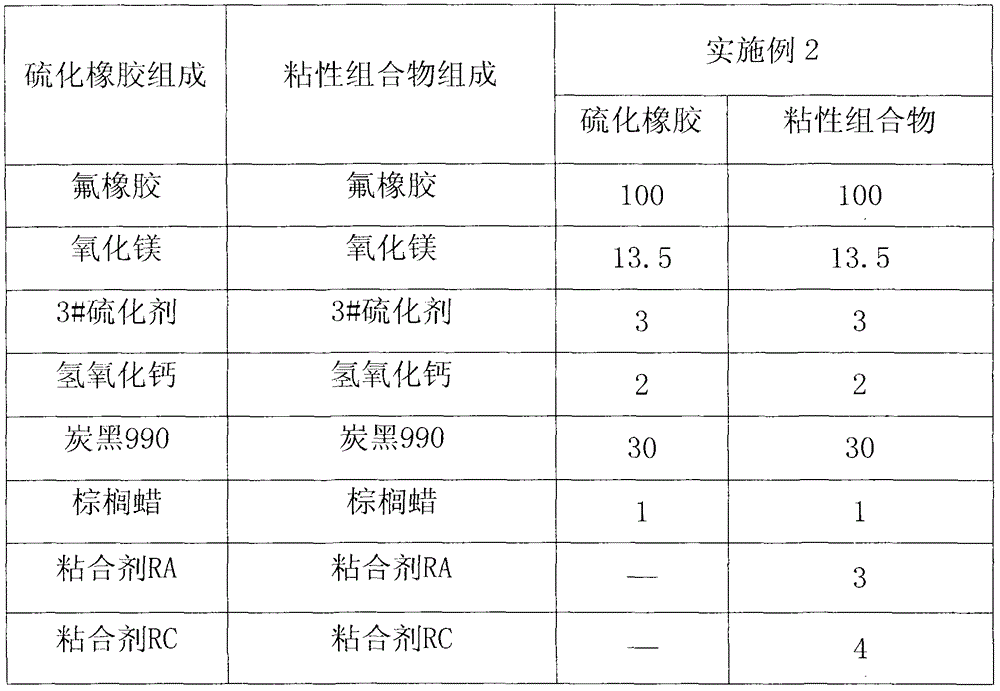

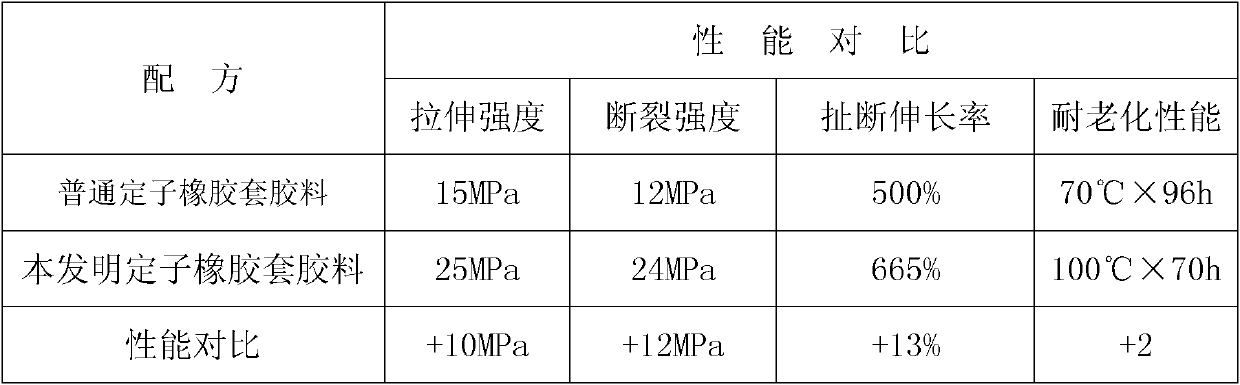

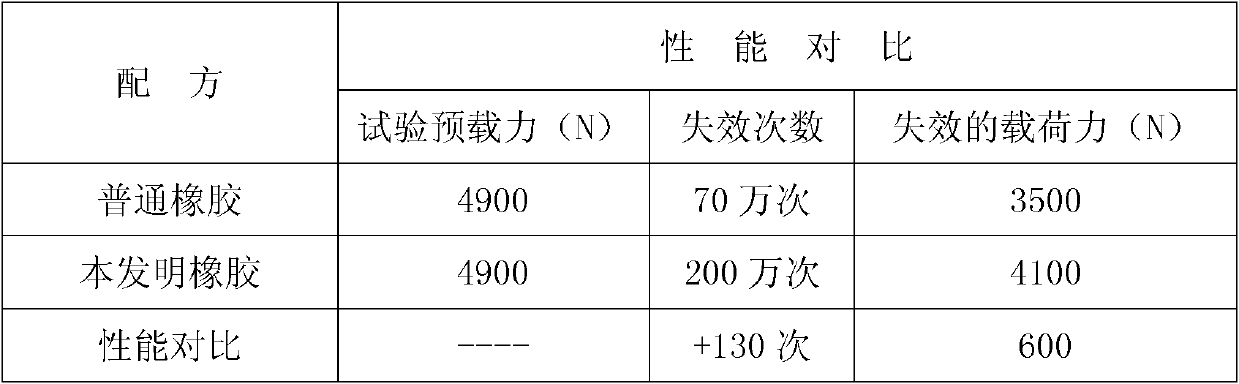

Method for adhering vulcanized rubber to metal

The invention relates to the field of adhesion between rubber and metal, in particular to a method for bonding vulcanized rubber to metal. The method comprises the steps of: coarsening and degreasing an adhesion surface between the vulcanized rubber and the metal; paining thermally-vulcanized adhesive on the processed adhesion surface between the metal and the vulcanized rubber; putting a transition layer on the adhesion surface between the metal and the vulcanized rubber in a painting or adhering way; and adhering the vulcanized rubber to the metal at high intensity in the manner of thermal vulcanization. The adhesion method belongs to a thermally-vulcanized adhesion method. Compared with a common cold adhesion method, the adhesion method is high in adhesion intensity, the peel strength of a 180-degree peel sample can reach 13KN / m, and the adhesion surface is good in toughness and better in dynamic fatigability. The method is wide in applicability, and is particularly suitable for the condition that the surface of the rubber has the structure and can not realize the high-intensity adhesion. The method has the advantages of being simple in operation, high in applicability, low in cost, easy to popularize, and suitable for the industrial production.

Owner:洛阳双瑞橡塑科技有限公司

Rubber sizing material of screw stator sleeve of prestressed vacuum grouting pump and preparation method thereof

The invention discloses a rubber sizing material of a screw stator sleeve of a prestressed vacuum grouting pump. The rubber sizing material comprises the following raw materials in part by weight: 85 to 90 parts of natural rubber, 0.5 to 0.7 part of butyl rubber, 1.1 to 1.3 parts of silicon rubber VMQ, 4 to 6 parts of carboxyl butadiene acrylonitrile rubber, 1.5 to 2.0 parts of methyl fluorinatedsilicon rubber, 2 to 4 parts of nano zinc oxide, 0.4 to 0.6 part of magnesium oxide, 0.3 to 0.5 part of stearic acid, 0.3 to 0.6 part of sulfur, 0.2 to 0.4 part of age resister RD, 0.5 to 1.5 parts of age resister MB, 8 to 12 parts of carbon black N550, 0.1 to 0.3 part of accelerator NOBS, 3 to 5 parts of paraffin, 0.2 to 0.3 part of scorch retarder CTP and 4 to 6 parts of soybean oil. In the preparing process, after part of formula raw materials are subjected to sizing material plasticization as required, other formula raw materials are added to carry out sizing material mixing and finally, a curing system is added to carry out mill run 5 to 7 times. The screw stator sleeve product of the vacuum grouting pump, which is produced according to the rubber formula, has excellent thermal agingresistance and tear resistance and also has excellent dynamic fatigue resistance.

Owner:HEFEI SHICHUAN ENG MACHINERY

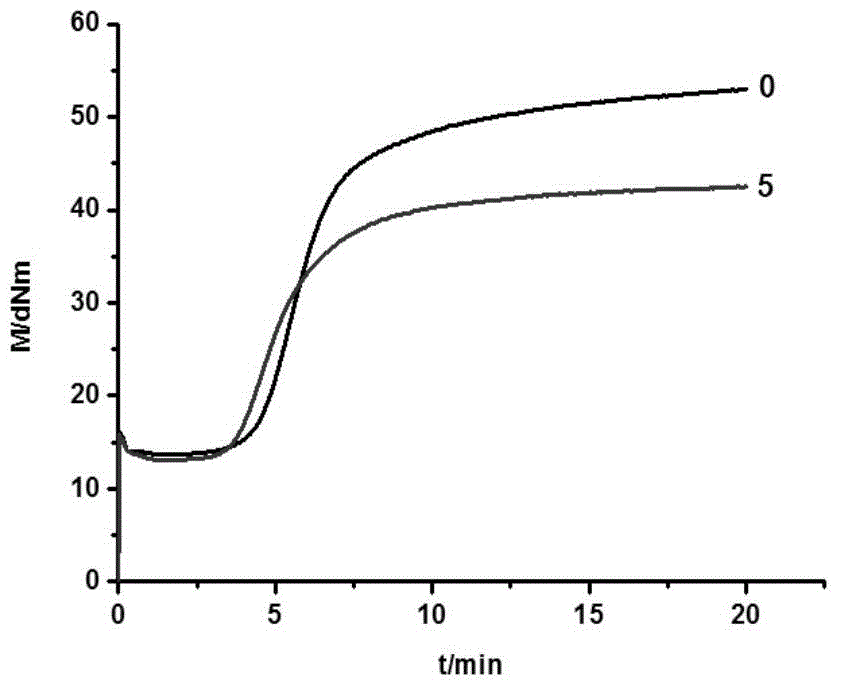

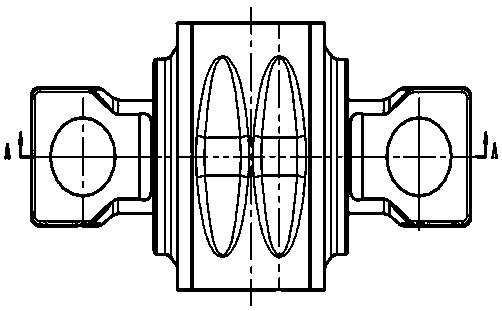

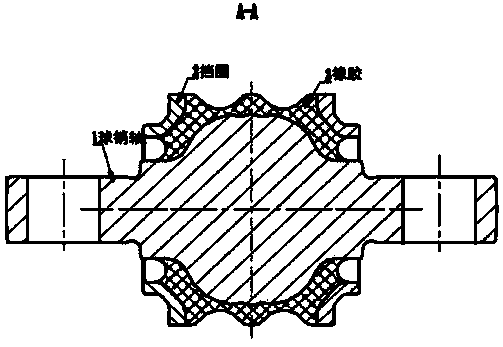

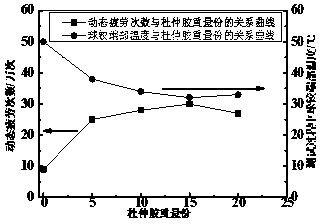

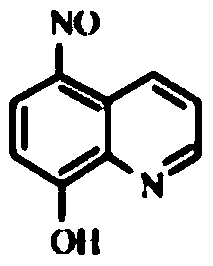

Fatigue-resistant gutta-percha spherical hinge for air suspension and preparation method of fatigue-resistant gutta-percha spherical hinge

The invention relates to a fatigue-resistant gutta-percha spherical hinge for an air suspension. The gutta-percha spherical hinge is prepared from the following basic components in proportion: 50-90 parts of natural rubber, 0-20 parts of isoprene rubber, 0-20 parts of butadiene rubber, 0-20 parts of gutta percha, 4-8 parts of zinc oxide, 1-3 parts of stearic acid, 4-10 parts of tackifying resin, 1-10 parts of an anti-aging agent, 70-130 parts of carbon black, 0-15 parts of oil, 4.5-6.5 parts of a vulcanizing agent, 1-3 parts of an accelerant and 0.1-1 part of a scorch retarder. The spherical hinge has the advantages that a certain amount of gutta percha is added to a formula for the spherical hinge to replace a part of the natural rubber in a spherical hinge rubber material, and on the premise that the hardness and rigidity of the spherical hinge are guaranteed, the dynamic fatigue performance of the spherical hinge is improved, and dynamic heat generation of the spherical hinge is reduced.

Owner:江苏华永复合材料有限公司

Rubber compound with low dynamic/static stiffness ratio, preparation method thereof, and mounting structure

ActiveCN110358155ASatisfy load bearing and vibration reductionLow dynamic to static ratioCarbon blackPlasticizer

The invention provides a rubber compound with a low dynamic / static stiffness ratio, a preparation method thereof, and a mounting structure. The rubber compound with the low dynamic / static stiffness ratio comprises, by weight, 50-95 parts of natural rubber, 5-50 parts of cis-polybutadiene rubber, 3-10 parts of zinc oxide, 0.5-5 parts of 2-ethyl zincate, 1-5 parts of a chemical anti-aging agent, 1-5parts of a physical anti-aging agent, 30-50 parts of carbon black, 0.5-5 parts of a coupling agent, 0-10 parts of a plasticizer, 0.5-3 parts of sulfur and 1-6 parts of a promoter. The natural rubberand cis-polybutadiene rubber are used together, and the components such as 2-ethyl zincate and the coupling agent are also used, so that the prepared rubber compound has a good static stiffness and alow dynamic stiffness, thereby the rubber compound with the low dynamic / static stiffness ratio is obtained.

Owner:NUOBO RUBBER PRODION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com