Anti-aging agent composition, anti-aging agent masterbatch and rubber composition

A technology of anti-aging agent composition and rubber composition, which is applied in the fields of anti-aging agent masterbatch and rubber composition, anti-aging agent composition, and can solve problems such as affecting health, powder staying for a long time, unfavorable tire lamination and molding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1: the preparation of antioxidant masterbatch

[0088] Formulation: The formulations of anti-aging agent masterbatches M1-M12 are shown in Table 1.

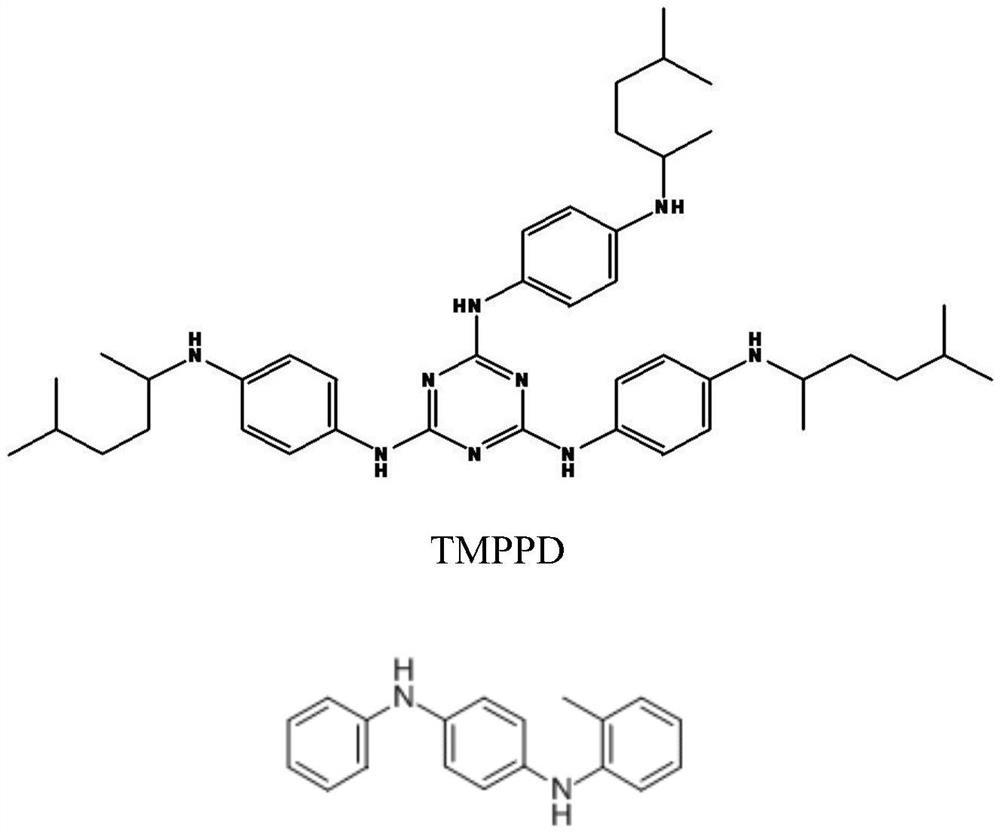

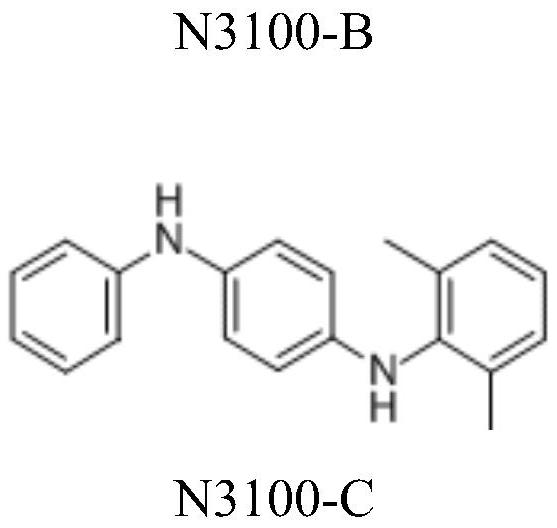

[0089] Preparation process: initial temperature 60°C, speed 70rpm, add rubber (EDPM\SBR\IR) pressure plug, add EVA pressure plug after 60 seconds, add stearic acid and 1 / 2 naphthenic oil after 30 seconds and press the plug , after mixing evenly, add anti-aging agent (TMPPD\N3100-B\N3100-C) and the remaining 1 / 2 naphthenic oil pressure plug, mix evenly, discharge the glue and use an open mill to take out the tablet to obtain the anti-aging agent masterbatch M1- M12.

[0090] Table 1: Formula of antioxidant masterbatch (unit: parts by mass)

[0091]

[0092]

Embodiment 2

[0093] Embodiment 2: the preparation of tire compound

[0094] Formula: the formula of tire compound 1-11 is shown in Table 2.

[0095] making process:

[0096] 1. Add natural rubber SCR5, synthetic rubber BR, carbon black N550, ZnO, SA, aromatic oil and anti-aging agent to the internal mixer, and knead the whole mixture until the maximum temperature between 110°C and 190°C is reached;

[0097] 2. Cool the whole mixture to a temperature below 100°C, then add accelerator NS and crosslinker S, knead and integrate the mixture until the maximum temperature below 110°C;

[0098] 3. The resulting composition is calendered into a sheet shape (thickness is about 2mm), to obtain unvulcanized rubber sheets, to measure their vulcanization characteristics t10 and t90;

[0099] 4. Vulcanized at 145°C for 30 minutes to obtain a vulcanized film to measure its mechanical properties, ozone aging resistance, weather aging resistance and dynamic fatigue aging resistance.

[0100] Table 2: Tire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com