Method for adhering vulcanized rubber to metal

A technology of vulcanized rubber and bonding method, used in the field of rubber and metal bonding, can solve the problems of low bonding strength, bonding failure, poor toughness, etc., and achieve the effects of good dynamic fatigue, high brittleness and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] 1. Preparation of Adhesive Transition Layer

[0021] One method is to use a mechanical device capable of kneading and shearing to process the viscous composition into a thin sheet of 0.8 mm to 1.5 mm for use, and the thin sheet can be directly used as an adhesive transition layer.

[0022] Another method is to dissolve the viscous composition flakes in an organic solvent. The types of organic solvents include toluene, xylene, cyclohexane, gasoline, etc.; stir for (10-15) minutes to accelerate dissolution, and make it used as a transition layer solvent-based adhesives.

[0023] 2. Bonding

[0024] Grind, degrease, and clean the bonding surfaces of vulcanized rubber and metal, and then spray or brush hot vulcanizing adhesives on the bonding surfaces of rubber and metal, such as Chemlok 252X, Xibang 24, Rohm and Haas P- For 11 and 538 double-coated adhesives, after the heat vulcanized adhesive is completely dry, brush or spray the transition layer adhesive on the metal a...

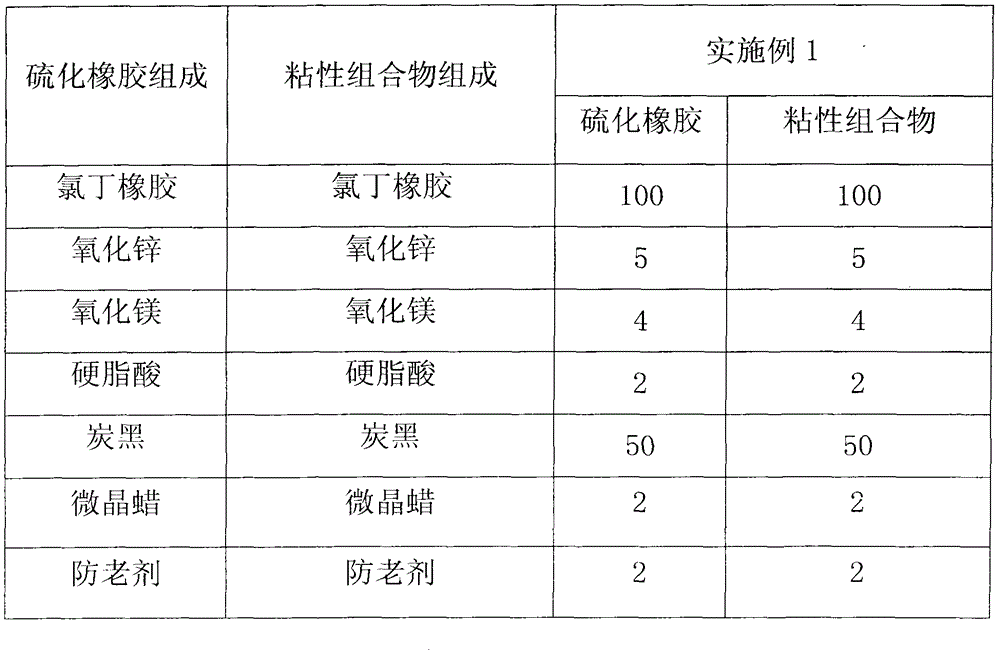

Embodiment 1

[0026] In this embodiment, the components of the vulcanized rubber and the viscous composition are the same, and the specific composition is shown in Attached Table 1, and the metal is stainless steel. The transition layer is a thin sheet of adhesive composition.

[0027] (1) Process the viscous composition into thin slices of 0.8 mm to 1.5 mm by using an open mill, and the thin slices need to be uniform in thickness and smooth in surface.

[0028] (2) Polish the vulcanized rubber bonding surface with 80-mesh sandpaper, then clean the bonding surface with acetone (2 to 3 times), and dry it for use. The metal surface is cleaned with acetone (2 to 3) times after sandblasting, and then dried for use.

[0029] (3) First coat a layer of Chemlok 205 heat vulcanizing adhesive on the treated metal bonding surface, let it dry for (20-30) minutes, and then apply a layer on the metal and vulcanized rubber bonding surface respectively Chemlok 252X adhesive. Then let it stand for (20-30...

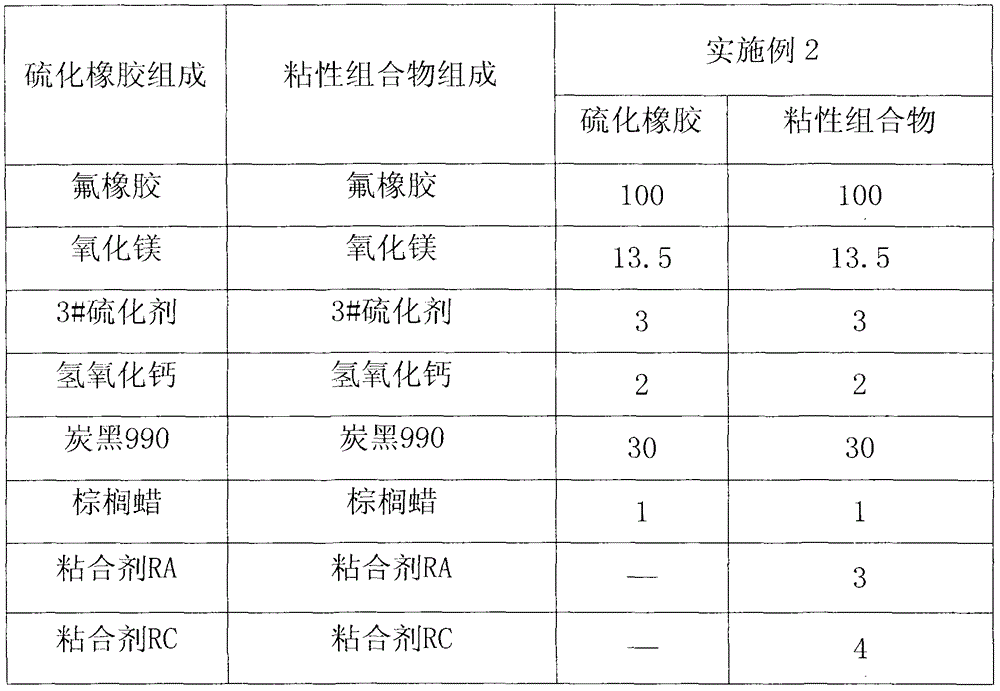

Embodiment 2

[0033] In this embodiment, the components of the vulcanized rubber and the viscous composition are similar, and the specific composition is shown in Attached Table 2, and the metal is stainless steel. The transition layer is a solvent-type adhesive prepared by dissolving the viscous composition in an organic solvent.

[0034] (1) Take 10 g of the viscous composition and cut it into granules, the maximum length of which should not exceed 1 cm. It was then put into 20 g of ethyl acetate solvent. In order to speed up the dissolution, it can be stirred for (12-15) minutes and placed for later use.

[0035] (2) The bonding surface treatment of vulcanized rubber and metal can adopt the steps (2) and (3) in Embodiment 1.

[0036] (3) Apply Kemlok 607 heat-vulcanizing adhesive to the bonded surfaces of vulcanized rubber and metal after treatment, apply twice and leave to dry (20-30) minutes before use. Every time it should be painted evenly, without any leakage, the dosage of Kemlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com