Rubber compound with low dynamic/static stiffness ratio, preparation method thereof, and mounting structure

A technology of dynamic-to-static ratio and sizing material, which is applied to the suspension structure applied with the sizing material, the preparation of the above-mentioned sizing material, and the field of low-dynamic-to-static ratio sizing material, can solve the problem of low dynamic-to-static ratio, and no suitable low-dynamic-static ratio sizing material products, etc. problems, to achieve the effect of satisfying the load and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] During the preparation of the low dynamic-static ratio rubber material of this embodiment, it adopts the rubber two-stage mixing process, and its preparation method includes the following steps:

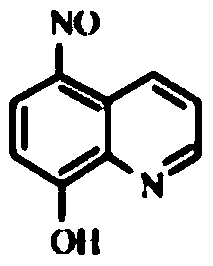

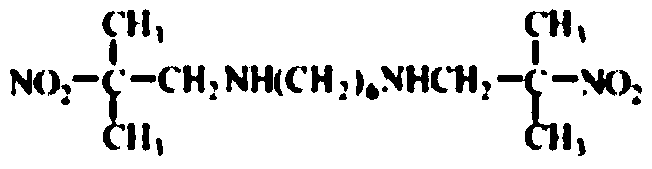

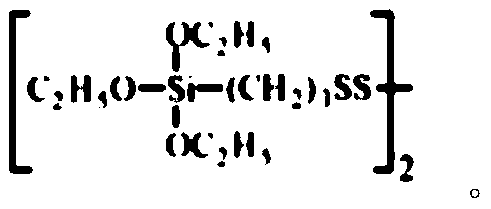

[0046] Step a, rubber mixing in section A: put natural rubber and terminal carbon black modified butadiene rubber into the internal mixer and mix for 55-65s, such as 60s, and then put in zinc oxide, zinc 2-ethylate, and anti-aging agent 6PPD , anti-aging agent S-TMQ, paraffin, high flash point paraffin oil mixed for 115-125s, such as 120s, continue to add carbon black and coupling agent and mix for 235-245s, such as 240s to 130-150℃, such as 140℃ for discharge Glue, and then enter the open mill to produce sheets.

[0047] Step b, rubber mixing in section B: put the rubber in section A into the internal mixer and knead for 55-65s, such as 60s, then add sulfur and accelerator and knead for 235-245s, such as 240s, and control the temperature of the rubber within 110°C ( For exam...

preparation example

[0048] Using the above preparation method, a number of specific preparation examples of rubber materials were carried out, and the parts by weight of each rubber material constituent component in each preparation example are shown in the table below. Among them, corresponding to each preparation example, the composition of a comparative example as an effect comparison is also given in the following table, and the high cis-butadiene rubber used is still the rubber product of Zeon Corporation of Japan. The test results of the rubber materials prepared by each preparation example and comparative example are still listed in the following table after inspection.

[0049]

[0050]

[0051] It can be seen from the above table that, using the raw material components and parts by weight of this example, the prepared rubber has a lower dynamic-static ratio, which can meet the performance requirements of the rubber mount for bearing, vibration reduction, and vibration isolation. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com