A shock-absorbing rubber

A technology of shock-absorbing rubber and natural rubber, applied in the field of rubber, can solve the problems of reduced shock-absorbing effect, failure to achieve vibration isolation, shock absorption, etc., and achieve the effects of increased life, low creep, and small dynamic-to-static ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The formula for the shock-absorbing rubber with a hardness of 55HA is as follows:

[0026] .

[0027] Adopt the existing method to make shock-absorbing rubber finished products, the specific process is as follows:

[0028] 1. Weighing: Weigh each raw material according to the above ratio;

[0029] 2. Mixing: first add natural rubber to the open mixer for 5-10 minutes, and then feed in the following order: natural rubber--activator--anti-aging agent--accelerator--carbon black--sulfur;

[0030] 3. The next piece: after all the materials are fully mixed, the next piece is formed, and the thickness is about 5-8mm;

[0031] 4. Vulcanization: The formed semi-finished product is vulcanized by a flat vulcanizing machine, the vulcanization temperature is 160°C, and the time is 30 minutes.

[0032] In the present invention, zinc oxide belongs to active agent, and protective wax belongs to antiaging agent.

[0033] There is no special requirement for the order of adding raw ...

Embodiment 2

[0045] The formula of shock-absorbing rubber with a hardness of 70HA is as follows:

[0046] .

[0047] Adopt the same process condition as embodiment 1 to make shock-absorbing rubber finished product.

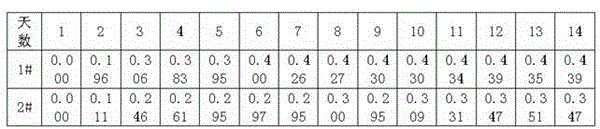

[0048] Creep test

[0049] The comparison sample is the WIF0C0RE023 product produced and sold by Wuxi Fuerkang Technology Co., Ltd. (hardness 70HA, the existing product is made of natural rubber and auxiliary materials under the same process conditions, but the selected auxiliary materials are different from the above shock-absorbing rubber auxiliary materials) .

[0050] experiment procedure:

[0051] 1. Preload to 0.5% of the rated load, stop for 3 seconds, and reset the force and displacement;

[0052] 2. Load to 3KN at a speed of 5mm / min, and record the displacement at this time;

[0053] 3. Keep the load constant, and record the deformation corresponding to the compression time of 24 hours for 13 days.

[0054] The result is as follows:

[0055]

[0056] Where...

Embodiment 3

[0059] The formulation of shock-absorbing rubber is as follows:

[0060] .

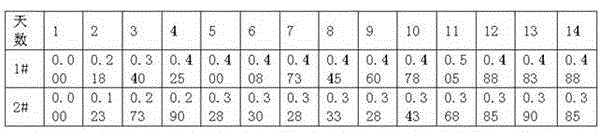

[0061] Record the above shock-absorbing rubber as 2# (hardness 48HA). The W2FT6050001 product produced and sold by Wuxi Fuerkang Technology Co., Ltd. (recorded as 1#, its hardness is 58HA, this existing product is produced by natural rubber and auxiliary materials using the same process conditions, but the selected auxiliary materials are the same as the above shock absorption Rubber accessories are different) for comparison.

[0062] static test

[0063] Test temperature: 22±2℃

[0064] Loading and unloading speed: 10mm / min

[0065] Maximum load: 1.3 times the rated load

[0066] Entrance force: 0.005 times rated load

[0067] experiment procedure:

[0068] 1. The first load: preload at a speed of 10mm / min to 1.3 times the rated torque, and then unload. Hold for 15s.

[0069] 2. The second load: compress to 1.3 times the rated torque at a speed of 10mm / min, and unload. Record loading and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com