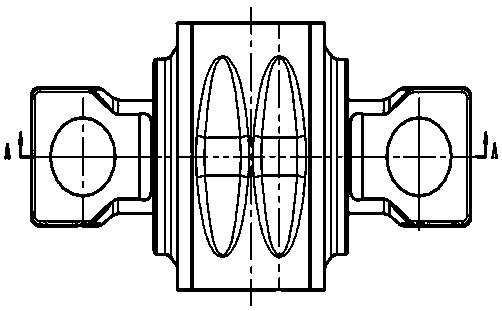

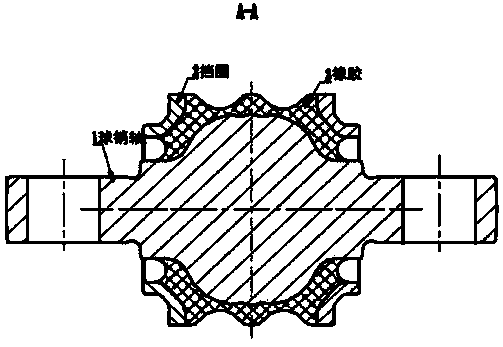

Fatigue-resistant gutta-percha spherical hinge for air suspension and preparation method of fatigue-resistant gutta-percha spherical hinge

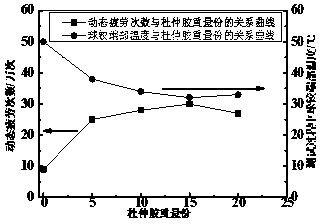

An air suspension and fatigue-resistant technology, which is applied in the field of Eucommia rubber ball joint preparation, can solve problems such as the decline in fatigue performance of ball joints, achieve the effects of reducing dynamic heat generation and improving dynamic fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The fatigue-resistant eucommia rubber ball hinge for air suspension of the present invention is prepared by the following formula;

[0027]

[0028]

[0029] Utilize above-mentioned formula to prepare the concrete preparation method of spherical joint as follows:

[0030] S1 rubber mixing: place Eucommia rubber in an oven at 75°C for 8 hours, put natural rubber, butadiene rubber, and Eucommia rubber into the internal mixer, and mix for 4 minutes, then add zinc oxide, stearic acid, anti-aging agent, and thickener Put the agent into the internal mixer, mix for 2 minutes, then add carbon black and oil into the internal mixer and mix for 1.5 minutes, and leave the material for 10 hours to obtain a section of mixed rubber. Then, mix one section of mixed rubber with vulcanizing agent, accelerator, The anti-scorch agent was added to the internal mixer and mixed for 4 minutes to obtain the two-forged mixed rubber, and then the two-forged mixed rubber was thinly passed on ...

Embodiment 2

[0034] The fatigue-resistant eucommia rubber ball hinge for air suspension of the present invention is prepared by the following formula;

[0035]

[0036] Utilize above-mentioned formula to prepare the concrete preparation method of spherical joint as follows:

[0037] S1 rubber mixing: place Eucommia rubber in an oven at 75°C for 8 hours, put natural rubber, butadiene rubber, and Eucommia rubber into the internal mixer, and mix for 4 minutes, then add zinc oxide, stearic acid, anti-aging agent, and thickener Put the agent into the internal mixer, mix for 2 minutes, then add carbon black and oil into the internal mixer and mix for 1.5 minutes, and leave the material for 10 hours to obtain a section of mixed rubber. Then, mix one section of mixed rubber with vulcanizing agent, accelerator, The anti-scorch agent was added to the internal mixer and mixed for 4 minutes to obtain the two-forged mixed rubber, and then the two-forged mixed rubber was thinly passed on the open mil...

Embodiment 3

[0041] The fatigue-resistant eucommia rubber ball hinge for air suspension of the present invention is prepared by the following formula;

[0042]

[0043]

[0044] Utilize above-mentioned formula to prepare the concrete preparation method of spherical joint as follows:

[0045] S1 rubber mixing: place Eucommia rubber in an oven at 75°C for 8 hours, put natural rubber, butadiene rubber, and Eucommia rubber into the internal mixer, and mix for 4 minutes, then add zinc oxide, stearic acid, anti-aging agent, and thickener Put the agent into the internal mixer, mix for 2 minutes, then add carbon black and oil into the internal mixer and mix for 1.5 minutes, and leave the material for 10 hours to obtain a section of mixed rubber. Then, mix one section of mixed rubber with vulcanizing agent, accelerator, The anti-scorch agent was added to the internal mixer and mixed for 4 minutes to obtain the two-forged mixed rubber, and then the two-forged mixed rubber was thinly passed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com