Rubber sizing material of screw stator sleeve of prestressed vacuum grouting pump and preparation method thereof

A screw stator, rubber compound technology, applied in the field of rubber vulcanization, can solve the problems of shadow bushing life, rubber block, bushing falling off, etc., to achieve good comprehensive performance, strong adhesion, aging resistance and other high performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: A rubber compound for the screw stator cover of a prestressed vacuum grouting pump, the weight parts of which are composed of raw materials are: natural rubber 86, butyl rubber 0.6, silicone rubber VMQ 1.2, carboxylated nitrile rubber 5, methyl fluorosilicone Rubber 1.8, nano zinc oxide 3, magnesium oxide 0.5, stearic acid 0.4, sulfur 0.5, antioxidant RD 0.3, antioxidant MB 1.0, carbon black N550 9, accelerator NOBS 0.2, paraffin wax 3, anti-scorch agent CTP 0.2, large soybean oil6. .

[0017] The preparation method comprises the following steps:

[0018] (1) Plastic training: Start the internal mixer, put natural rubber, isoprene rubber, butadiene rubber, and styrene-butadiene rubber into the internal mixer for plastic training, and knead until several kinds of rubber are fully fused. When the temperature reaches 110- 125°C, start discharging, stop and cool for 23-25 hours after discharging;

[0019] (2) Mixing: Add the above-mentioned cooled plastic ru...

Embodiment 2

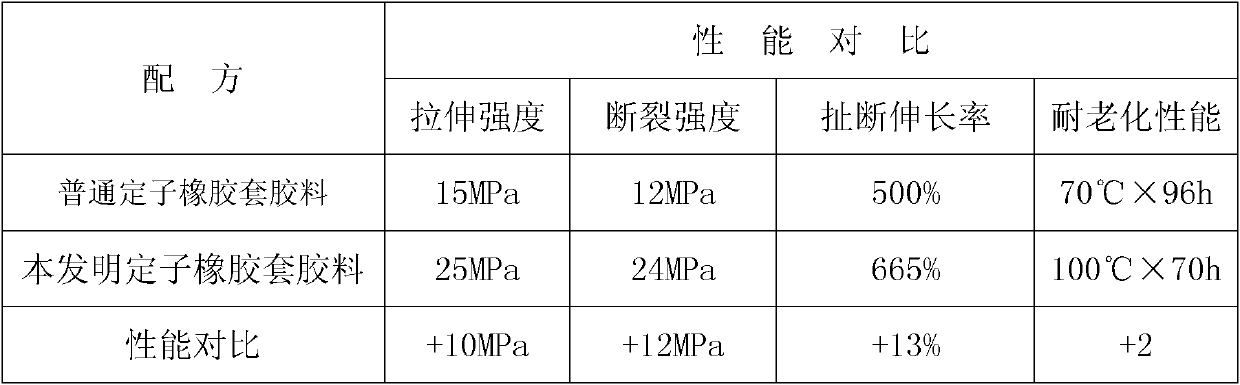

[0021] Embodiment 2: The stator rubber sleeve produced by the prestressed vacuum grouting pump screw stator sleeve rubber compound of the present invention is compared with the ordinary stator rubber sleeve as shown in the following table

[0022]

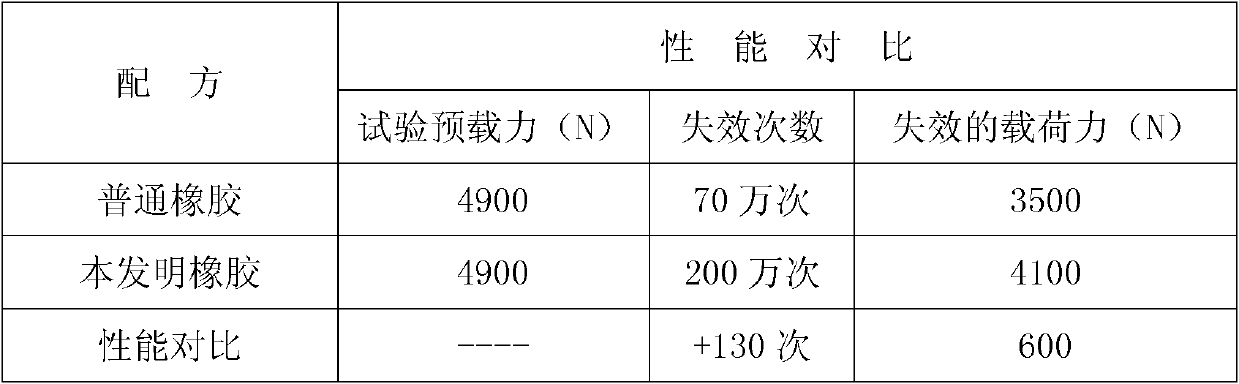

[0023] Rubber product of the present invention and ordinary rubber product dynamic fatigue test performance contrast

[0024] Test conditions: Conditions: preload: 4900N, amplitude: ±3mm, frequency: 3Hz, at least 1.2 million times

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com