Polyurethane microporous elastomer and sole material and damping material applying elastomer

A microcellular elastomer, polyurethane technology, applied in the fields of polyurethane microcellular elastomers, shock absorption materials, and shoe sole materials, can solve the problem of no obvious improvement in hydrolysis resistance, and achieve good hydrolysis resistance and good impact resistance. , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

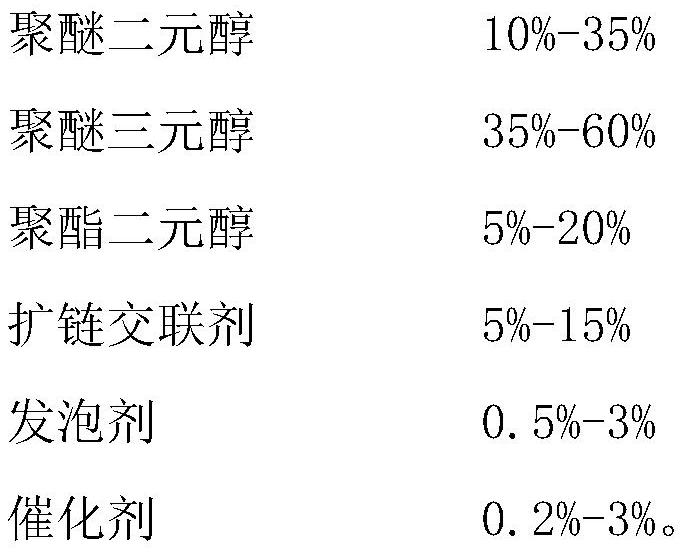

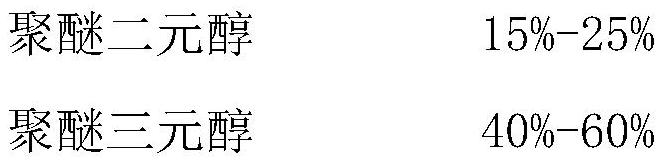

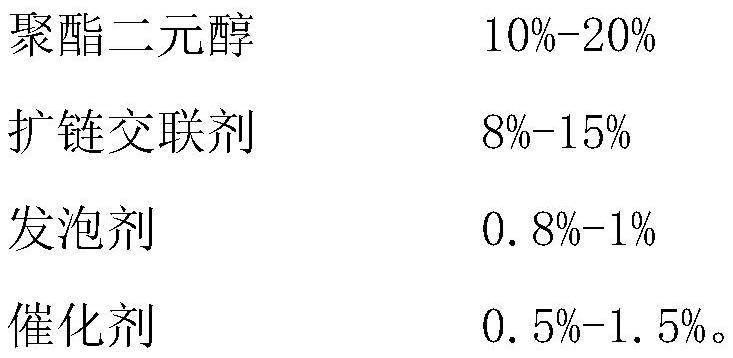

[0038] In this embodiment, the polyurethane microcellular elastomer is obtained by reacting the isocyanate component and the isocyanate-reactive component, and the molar ratio of the isocyanate group in the isocyanate component to the hydroxyl group in the isocyanate-reactive component is 1:1. Among them, the isocyanate component is 4,4'-diphenylmethane diisocyanate (MDI); the isocyanate reactive component includes 10% of polyether diol, 60% of polyether triol, 20% of Polyester diol, 5% chain-extending cross-linking agent, 2% blowing agent, and 3% catalyst.

[0039] Polyether diol, starting from propylene glycol, polymerized by propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average molecular weight is 3000;

[0040] Polyether triol, starting from glycerol, polymerized with propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average molecular weight is 4000;

[0041] Polyeste...

Embodiment 2

[0045] In this embodiment, the polyurethane microcellular elastomer is obtained by reacting the isocyanate component and the isocyanate-reactive component, and the molar ratio of the isocyanate group in the isocyanate component to the hydroxyl group in the isocyanate-reactive component is 1:1. Among them, the isocyanate component is selected from 4,4'-diphenylmethane diisocyanate (MDI); the isocyanate reactive component includes 15% of polyether diol, 50% of polyether triol, 18% of Polyester diol, 9.5% chain-extending cross-linking agent, 1% foaming agent, 1.5% catalyst, and 5% anti-wear agent.

[0046] Polyether diol, starting from propylene glycol, polymerized by propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average molecular weight is 2000;

[0047] Polyether triol, starting from glycerol, polymerized with propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average molecu...

Embodiment 3

[0052] In this embodiment, the polyurethane microcellular elastomer is obtained by reacting the isocyanate component and the isocyanate-reactive component, and the molar ratio of the isocyanate group in the isocyanate component to the hydroxyl group in the isocyanate-reactive component is 1:1.2. Among them, the isocyanate component is selected from 4,4'-diphenylmethane diisocyanate (MDI); the isocyanate reactive component includes 35% of polyether diol, 35% of polyether triol, 10% of Polyester diol, 13.6% chain-extending cross-linking agent, 0.5% foaming agent, 0.9% catalyst, and 5% anti-wear agent.

[0053] Polyether diol, starting from propylene glycol, polymerized from propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average molecular weight is 600;

[0054] Polyether triol, starting from glycerol, polymerized with propylene oxide and capped with ethylene oxide, the content of ethylene oxide is 15%, and the number average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com