Preparation material of scratch-resistant screen wiper rubber sheet and preparation method thereof

A scratch-resistant and wiper technology, which is applied in the automotive field, can solve the problems of difficult surface of wiper blades, poor weather resistance, and poor wiping effect, and achieves good wiping effect, long service life and excellent dynamic fatigue performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

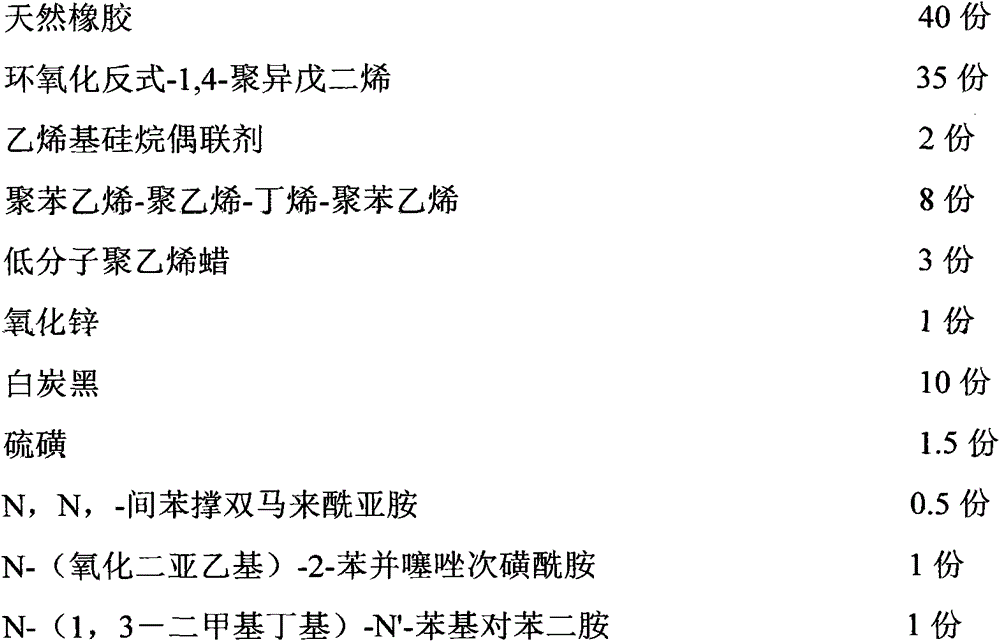

[0022] In the manufacturing process of the scratch-resistant wiper film of the present invention, the first step is to weigh the raw materials according to the following weight ratios:

[0023]

[0024] The second step is to carry out production and processing according to the following steps:

[0025] S1. Add the weighed zinc oxide and white carbon black into a high-speed mixer and mix for 10 minutes to obtain a mixed material;

[0026] S2, the weighed natural rubber, epoxidized trans-1,4-polyisoprene, vinyl silane coupling agent, polystyrene-polyethylene-butylene-polystyrene and processing aids , add to the kneader and stir for 20 minutes, then add the mixed material obtained in step S1 into the kneader, raise the temperature to 150°C, continue to mix for 40 minutes, then vacuum to -0.1MPa, keep at 150°C, continue to mix for 60 minutes, Finally discharge the material and filter the rubber in the rubber filter to obtain the basic rubber compound;

[0027] S3, adding the ...

Embodiment 2

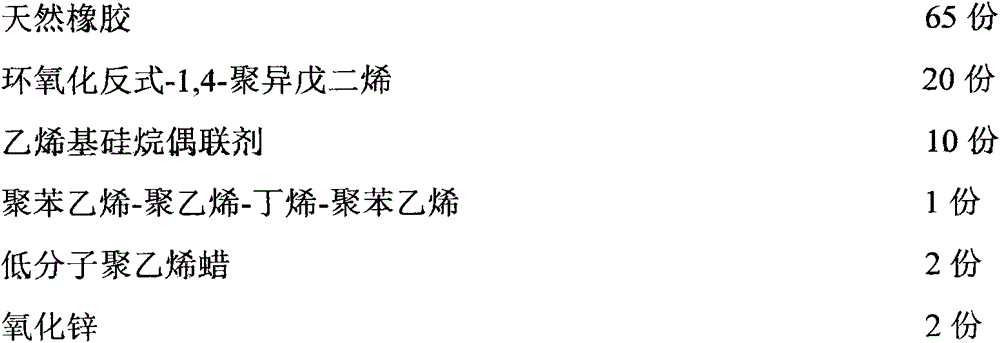

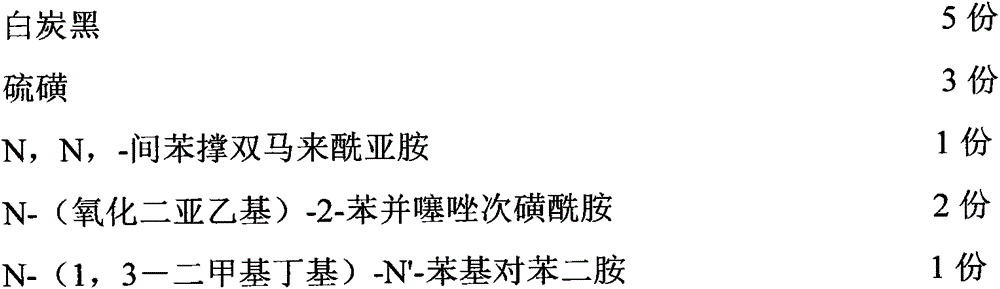

[0030] In the manufacturing process of the scratch-resistant wiper film of the present invention, the first step is to weigh the raw materials according to the following weight ratios:

[0031]

[0032]

[0033] The second step is to carry out production and processing according to the following steps:

[0034] S1. Add the weighed zinc oxide and white carbon black into a high-speed mixer and mix for 10 minutes to obtain a mixed material;

[0035] S2, the weighed natural rubber, epoxidized trans-1,4-polyisoprene, vinyl silane coupling agent, polystyrene-polyethylene-butylene-polystyrene and processing aids , add to the kneader and stir for 30 minutes, then add the mixed material obtained in step S1 into the kneader, raise the temperature to 150°C, continue to mix for 50 minutes, then vacuum to -0.1MPa, keep at 150°C, continue to mix for 60 minutes, Finally discharge the material and filter the rubber in the rubber filter to obtain the basic rubber compound;

[0036] S3,...

Embodiment 3

[0039] In the manufacturing process of the scratch-resistant wiper film of the present invention, the first step is to weigh the raw materials according to the following weight ratios:

[0040]

[0041] The second step is to carry out production and processing according to the following steps:

[0042] S1. Add the weighed zinc oxide and white carbon black into a high-speed mixer and mix for 10 minutes to obtain a mixed material;

[0043] S2, the weighed natural rubber, epoxidized trans-1,4-polyisoprene, vinyl silane coupling agent, polystyrene-polyethylene-butylene-polystyrene and processing aids , add to the kneader and stir for 40 minutes, then add the mixed material obtained in step S1 into the kneader, raise the temperature to 150°C, continue to mix for 60 minutes, then vacuum to -0.1MPa, keep at 150°C, continue to mix for 60 minutes, Finally discharge the material and filter the rubber in the rubber filter to obtain the basic rubber compound;

[0044] S3, adding the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com