Method for producing NDI/MDI based polyurethane micropore elastomer

A technology of microcellular elastomer and polyurethane, applied in the field of preparation of polyurethane microcellular elastomer, can solve the problem of high dynamic fatigue deformation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Polycaprolactone with a molecular weight of 2000 reacts with NDI at 120-140°C to obtain a prepolymer with an -NCO content of 8.2%——W NDI

[0026] Polycaprolactone with a molecular weight of 2000 reacts with MDI at 70-90°C to obtain a prepolymer with an -NCO content of 8.2%——W MDI

[0027] Take W MDI :W NDI = 5:1 Mix thoroughly at 90°C for later use.

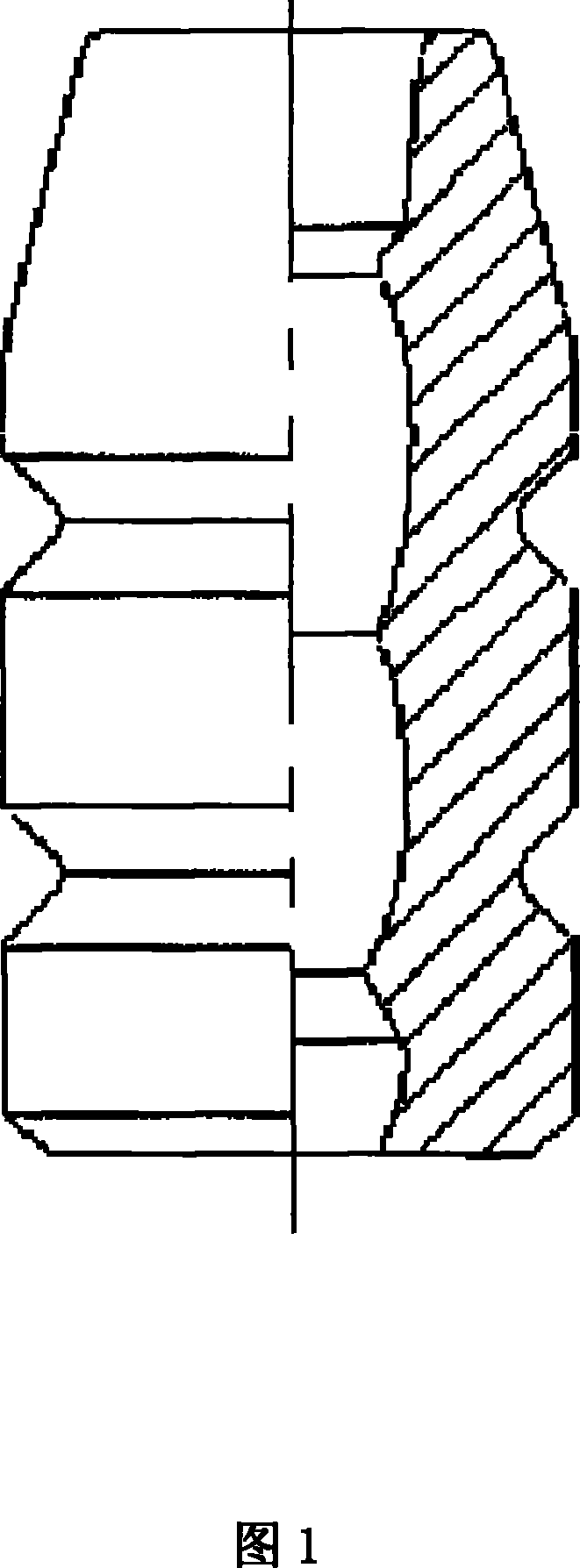

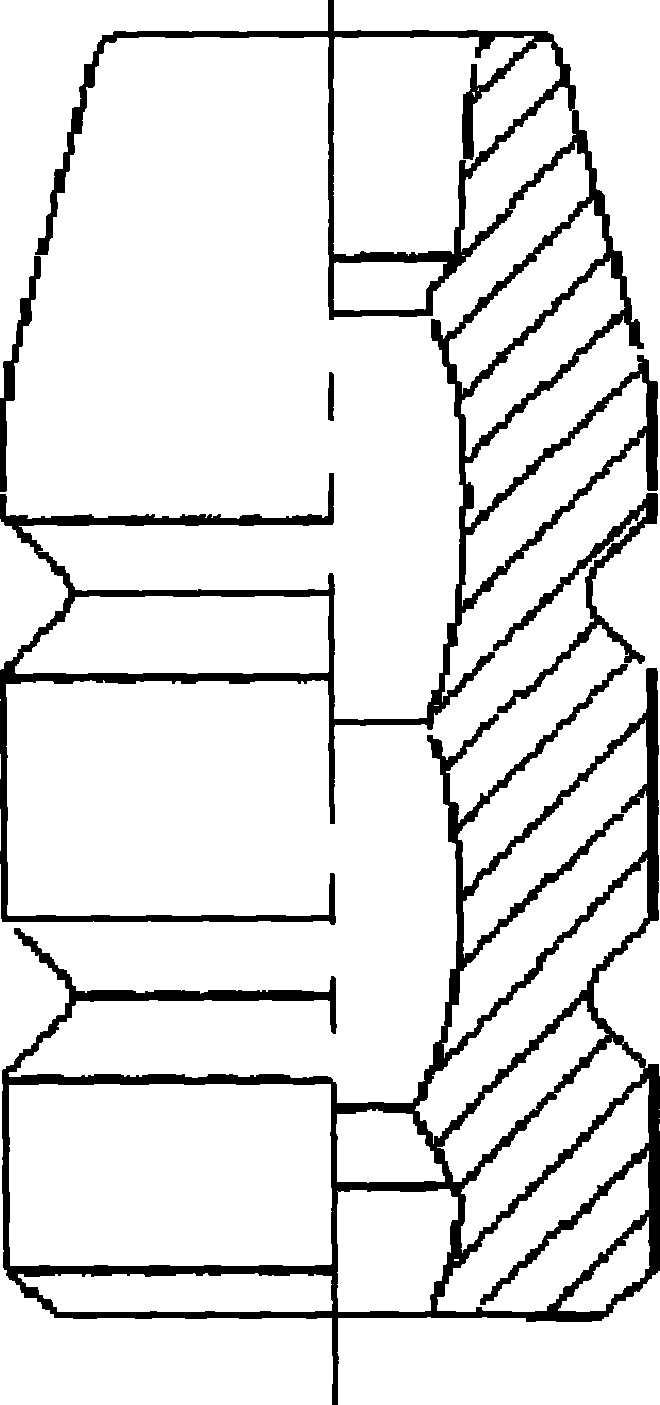

[0028] The cross-linking agent component is mainly 1.4 butanediol, and the auxiliary components include: blowing agent water, commercially available Dabco33Lv of the catalyst, commercially available DC 193 of the surfactant, etc., wherein the auxiliary components account for the total amount of the cross-linking agent 5%; use a low-pressure foaming machine, mix the prepolymer mixture and the crosslinking agent component according to the ratio of the isocyanate index to 100%, inject the reaction feed liquid into a mold at 90°C, and manufacture microcellular elastomer products (such as figure 1 ) and a test piece (150×1...

Embodiment 2

[0031] Take W MDI :W NDI = 4:1 Mix thoroughly at 90°C for later use. Others are the same as embodiment 1.

Embodiment 3

[0033] Take W MDI :W NDI = 3:1 Mix thoroughly at 90°C for later use. Others are the same as embodiment 2.

[0034] Table 1: Dynamic fatigue properties of microcellular elastomers prepared by comparative examples 1-2 and examples 1-3

[0035] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com