Trans-butadiene-isoprene rubber modified regenerated rubber as well as preparation method and purpose thereof

A technology of butadiene rubber and reclaimed rubber, applied in the field of reclaimed rubber, can solve the problems of difficult walking and maintenance of all-steel radial tires, and achieve the effect of improving dynamic fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

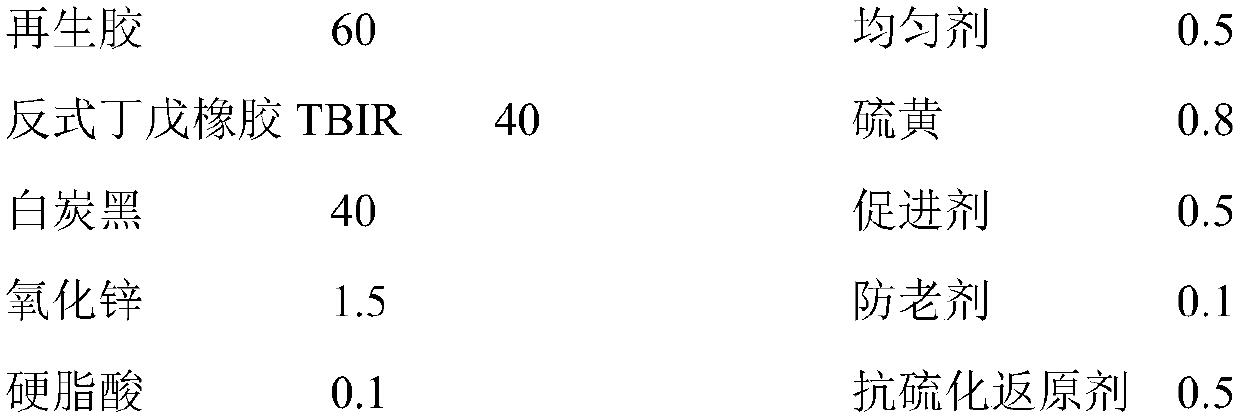

[0034] Trans-butadiene rubber TBIR modified reclaimed rubber consists of the following components in parts by weight:

[0035]

[0036]

[0037] Among the above rubber materials, the reclaimed rubber adopts recycled tire tread rubber powder, which contains 70% of natural rubber and 30% of carbon black; the molar content of butadiene structural units in trans-butylene rubber is 20%, and isoprene The molar content of olefinic units is 80%, the trans-1,4-structure content is 93%, and the Mooney viscosity is 80 (100°C, 3+4min). Prepare the rubber compound by mixing as follows:

[0038] (1) TBIR masterbatch was prepared by blending trans-butadiene rubber TBIR and 35 parts of carbon black N330. The mixing temperature was 70°C, the speed of the internal mixer was 70 rpm, and the mixing time was 16 minutes;

[0039] (2) Blend the TBIR masterbatch prepared in step (1) with 50 parts of reclaimed rubber, where the mixing temperature is 70°C, the speed of the internal mixer is 70rp...

Embodiment 2

[0045] In addition to the reclaimed rubber, the inner part of the reclaimed rubber is used, which contains 10% natural rubber, 60% butyl rubber and 30% white carbon black; the molar content of butadiene structural units in trans-butadiene rubber is 20%, The trans structure content is 90%, the Mooney viscosity is 60 (100°C, 3+4min), the filler is silica, and the rest are the same as in Example 1.

[0046] The mixing method and vulcanization of the sizing material in this embodiment are as described in Example 1.

Embodiment 3

[0048] Except that the amount of reclaimed rubber is 100 parts, the amount of TBIR is 5 parts, and the filler is calcium carbonate, the rest is the same as in Example 1.

[0049] The mixing method and vulcanization of the sizing material in this embodiment are as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com