EPDM/EPM engine synthetic brake fluid and expansion resistance rubber material and manufacturing process thereof

A technology of brake fluid and rubber compound, applied in the field of EPDM/EPM locomotive-resistant synthetic brake fluid expansion compound, can solve the problem of high price and achieve good protection, good heat resistance, and good elongation at break and resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment discloses an EPDM / EPM anti-motorcycle synthetic brake fluid expansion compound, which is characterized in that: the components are proportioned according to the mass ratio as follows:

[0060] EPDM: 70 parts; Zinc oxide: 4 parts;

[0061] Stearic acid SA: 3 parts; anti-aging agent BLE (liquid): 2.5 parts;

[0062] Antiaging agent SP (liquid): 3 parts; Antiaging agent RD: 1 part;

[0063] N550 carbon black: 60 parts; binary ethylene propylene glycol EPM: 20 parts;

[0064] Qiangwei Powder: 20 parts; Liquid EPDM: 20 parts;

[0065] Assisted cross-linking agent IS: 1 part; Accelerator DM: 1.5 parts;

[0066] Cross-linking agent 96% peroxide curing agent DCP: 1 part; polyethylene glycol: 2 parts.

Embodiment 2

[0068] This embodiment discloses an EPDM / EPM anti-motorcycle synthetic brake fluid expansion compound, which is characterized in that: the components are proportioned according to the mass ratio as follows:

[0069] EPDM: 80 parts; Zinc oxide: 3 parts;

[0070] Stearic acid SA: 1 part; anti-aging agent BLE (liquid): 2.5 parts;

[0071] Antiaging agent SP (liquid): 2 parts; Antiaging agent RD: 1 part;

[0072] N550 carbon black: 55 parts; binary ethylene propylene glycol EPM: 20 parts;

[0073] Qiangwei Powder: 20 parts; Liquid EPDM: 20 parts;

[0074] Assisted cross-linking agent IS: 0.5 parts; Accelerator DM: 1.5 parts;

[0075] Cross-linking agent 96% peroxide curing agent DCP: 0.5 parts; polyethylene glycol: 1.5 parts.

Embodiment 3

[0077] This embodiment discloses an EPDM / EPM anti-motorcycle synthetic brake fluid expansion compound, which is characterized in that: the components are proportioned according to the mass ratio as follows:

[0078] EPDM: 90 parts; Zinc oxide: 2 parts;

[0079] Stearic acid SA: 1 part; anti-aging agent BLE (liquid): 2.5 parts;

[0080] Antiaging agent SP (liquid): 2 parts; Antiaging agent RD: 1 part;

[0081] N550 carbon black: 50 parts; binary ethylene propylene glycol EPM: 20 parts;

[0082] Qiangwei powder: 22 parts; liquid EPDM: 20 parts;

[0083] Assisted cross-linking agent IS: 1.5 parts; Accelerator DM: 2 parts;

[0084] Cross-linking agent 96% peroxide curing agent DCP: 1.5 parts; polyethylene glycol: 2.5 parts.

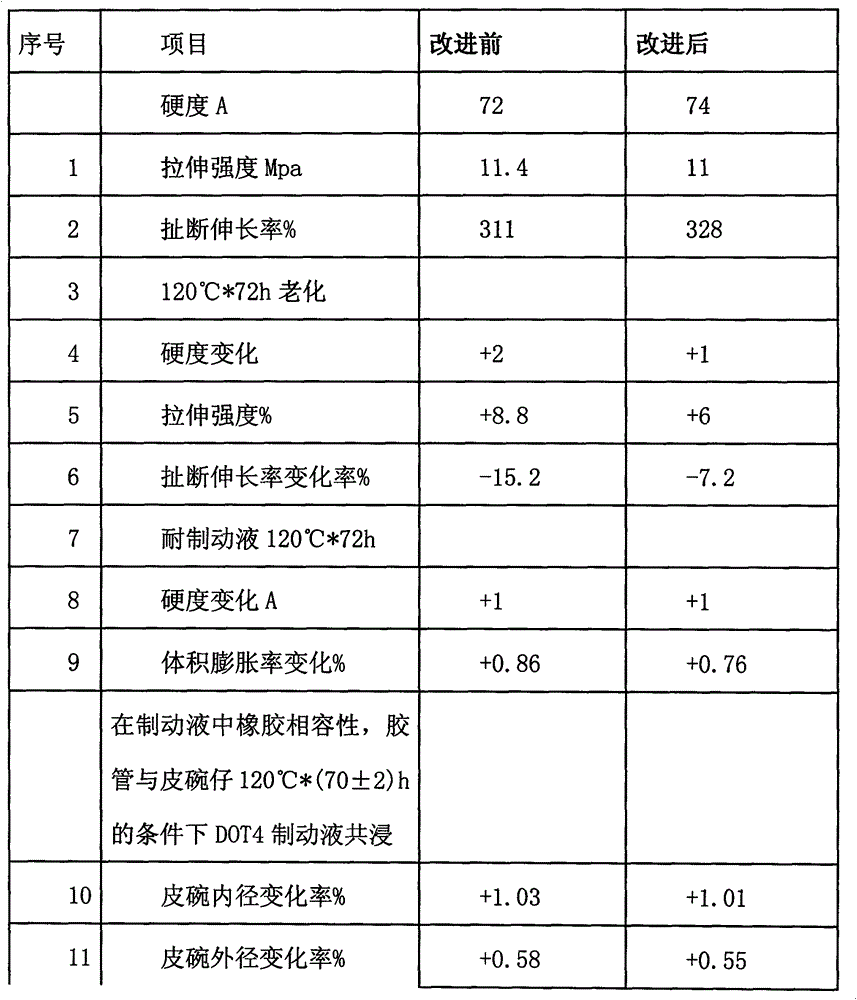

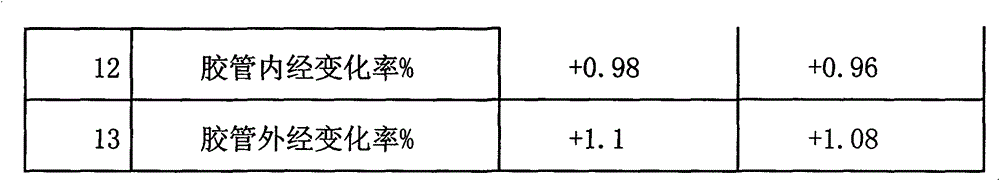

[0085] The overall quality of the products obtained in Examples 1-3 is good, the price is low, it will not expand in the brake fluid, and the softener will not be drawn out to cause the volume expansion, dissolution, and shrinkage of the main and auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com