Terminal-modified solution-polymerized butylbenzene copolymer and preparation method and application thereof

A solution-polymerized styrene-butadiene and end-group modification technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of the production line not running normally and continuously, reducing the rolling hysteresis of tires, and the surface of the rubber compound being not smooth, etc. Achieving good dynamic mechanical properties, speeding up the "powder eating" performance, and the effects of easy control of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

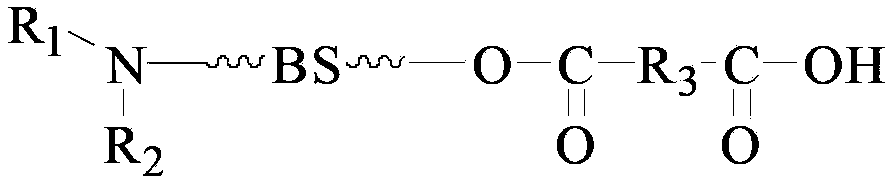

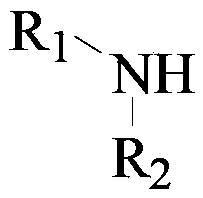

Method used

Image

Examples

Embodiment 1

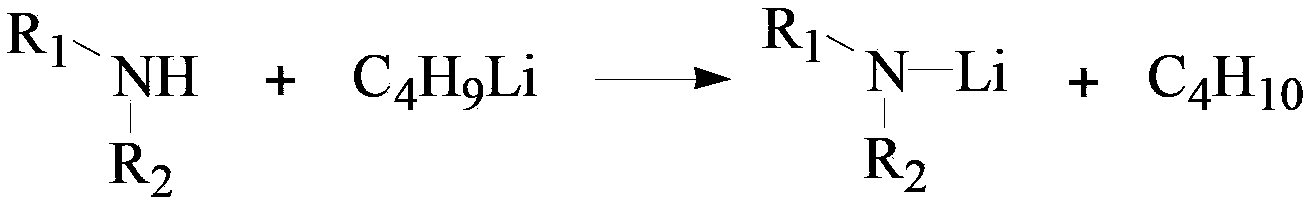

[0062] Under the protection of nitrogen in a clean and dry 150mL two-hole horn bottle, add 2.5g of dimethylamine to the other hole of the horn bottle with a syringe at a room temperature of 10°C, and then add 112.2mL of 0.5mol / L n-butyllithium , After shaking for 20 minutes, the reaction was complete, and the concentration of lithium dimethylamide was 0.48mol / L at this time.

Embodiment 2

[0064] Under the protection of nitrogen in a clean and dry 150mL two-hole horn bottle, add 5.1g of diisopropylamine to the other hole of the horn bottle with a syringe at room temperature 32°C, and then add 0.5mol / L n-butyllithium 103mL, the reaction was complete after shaking for 25min, and the concentration of lithium diisopropylamide was 0.47mol / L at this time.

Embodiment 3

[0066] Under the protection of nitrogen in a clean and dry 150mL two-hole horn bottle, add 8.05g of bis-(trimethylsilyl)amine to the other hole of the horn bottle with a syringe at a room temperature of 40°C, and then add 0.5mol / L 105mL of n-butyllithium was used, and the reaction was complete after shaking for 30 minutes. At this time, the concentration of bis-(trimethylsilyl)amide lithium was 0.44mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com