Method for preparing polymer/clay nano-composite

A technology of nanocomposite materials and polymers, which is applied in the field of preparation of polymer-based nanocomposite materials, can solve the problem that the modification efficiency of organic modifiers and coupling agents is not very high, and the performance of composite materials cannot be greatly improved. Problems such as large consumption of raw materials and energy, to achieve the effect of reducing mixing time, reducing energy consumption and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

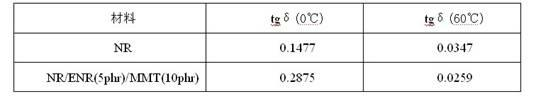

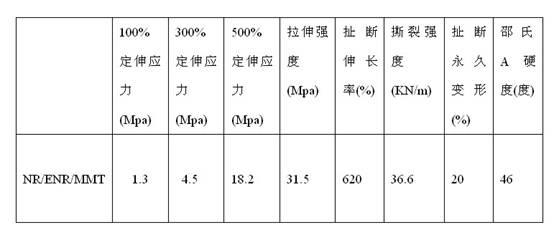

[0038]First add 8 parts of commercially available montmorillonite into water for stirring and dispersing, and the solid content of montmorillonite is controlled at 2% (weight); add 8 parts of montmorillonite to the above montmorillonite suspension, and the degree of epoxidation is 25% based on dry glue , a total solid content of 25% (weight) of epoxidized natural rubber latex, stirring and dispersing to prepare a montmorillonite dispersion; then adding 100 parts of the above montmorillonite dispersion to a total solid content of 60% (weight) based on dry rubber Stir and mix evenly in the natural rubber latex, and then use 10% (weight) calcium chloride solution for flocculation. The flocs were washed with water until neutral, and dried in a vacuum oven at 80°C to constant weight to obtain NR / ENR / MMT nanocomposites. The composite material is mixed and vulcanized by adding various compounding ingredients according to the commonly used rubber formula. The physical and mechanical p...

Embodiment 2

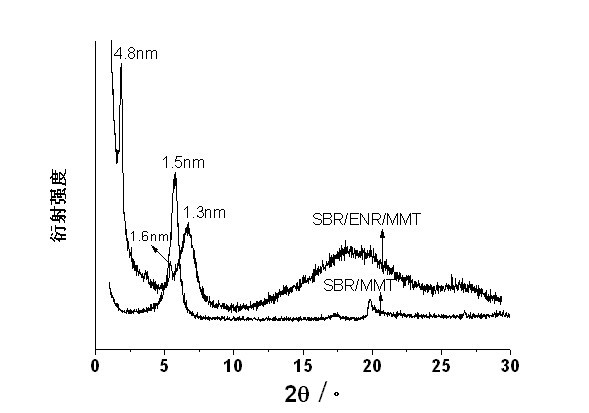

[0043] First 40 parts of commercially available montmorillonite are added into water and stirred, and the solid content of montmorillonite is controlled at 5% (weight); adding 25 parts of montmorillonite to the above-mentioned suspension of montmorillonite is 30% in terms of dry glue, and the degree of epoxidation is 30%. Total solids content is 25% epoxidized natural rubber latex, stirs and disperses and prepares montmorillonite dispersion; Adds above-mentioned montmorillonite dispersion again and is stirred in 100 parts of styrene-butadiene rubber latexes with total solids content of 20% in dry rubber Mix well, and then use 5% octadecyltrimethylammonium chloride solution for flocculation. The flocs were washed with water until neutral, and dried in a vacuum oven at 80°C to constant weight to obtain the SBR / ENR / MMT nanocomposite. The composite material is mixed and vulcanized by adding various compounding ingredients according to the commonly used rubber formula. The tensile ...

Embodiment 3

[0045] First add 20 parts of commercially available montmorillonite into water for stirring, and at the same time add 1 part of silane coupling agent KH560, wherein the solid content of montmorillonite is controlled at 10% (weight); add 10 parts ( In terms of dry rubber) the degree of epoxidation is 15%, and the total solid content is 10% of epoxidized natural rubber latex, stirring and dispersing to prepare montmorillonite dispersion; then add the above-mentioned montmorillonite dispersion to 100 parts in dry rubber Nitrile rubber latex and carboxylated styrene-butadiene latex mixed latex are stirred and mixed evenly, wherein the mixed latex contains 50 parts of nitrile rubber latex with a solid content of 20% based on dry rubber and 50 parts with a solid content of 20% based on dry rubber. % carboxylated styrene-butadiene latex. Then use 2% (weight) hydrochloric acid solution for flocculation, wash the flocs to neutrality, and dry them in a vacuum oven at 80°C to constant we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Stress at modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com