Coating-type binder used for bounding nitrile butadiene rubber and metal framework and preparation method

A technology of nitrile rubber and metal skeleton, which is applied in the direction of adhesive additives, adhesives, adhesive types, etc., can solve the problems of complicated and troublesome bonding operations, high cost of use, poor aging resistance, heat aging resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

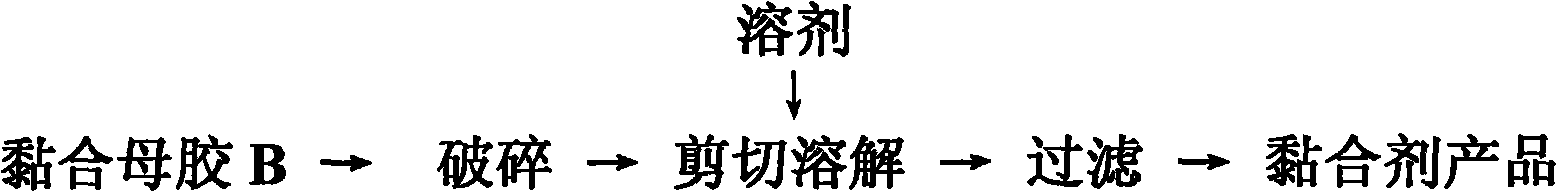

Method used

Image

Examples

Embodiment Construction

[0037] The following are examples of the present invention, and the practical use of the present invention is not limited to the examples.

[0038] Example Coated adhesive for bonding nitrile rubber and metal skeleton and preparation method

[0039] (1) Raw materials

[0040] Raw material name

[0041] (2) Production equipment

[0042] device name

[0043] (3) Group distribution ratio

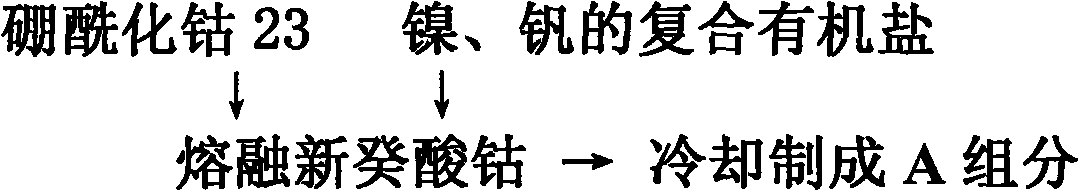

[0044] Table 1 Distribution ratio table of component A of composite cobalt salt binder (based on the mass of component A as 100%)

[0045]

[0046] Explanation: The adhesive agent used in this composite cobalt salt is an organic salt containing nickel and vanadium, and the total amount of metal is 10.2%, of which nickel is 7.02% and vanadium is 3.18%.

[0047] The synthetic weight is 100KG.

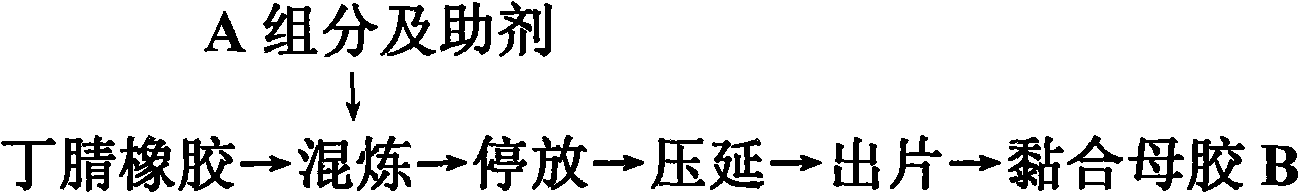

[0048] Table 2 Proportion table of adhesive masterbatch B (based on the mass of adhesive masterbatch B as 100%)

[0049]

[0050] Explanation: Component A of the composite ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com