Method for graphite ore enhanced flotation purification through microwave roasting pretreatment

A technology for pretreatment of graphite and microwave roasting, applied in chemical instruments and methods, flotation, inorganic chemistry, etc., can solve problems such as poor flotation effect, uneven particle size of embedding, difficulty in monomer dissociation, etc., to reduce grinding Mining time, improving flotation effect, improving the effect of dissociation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

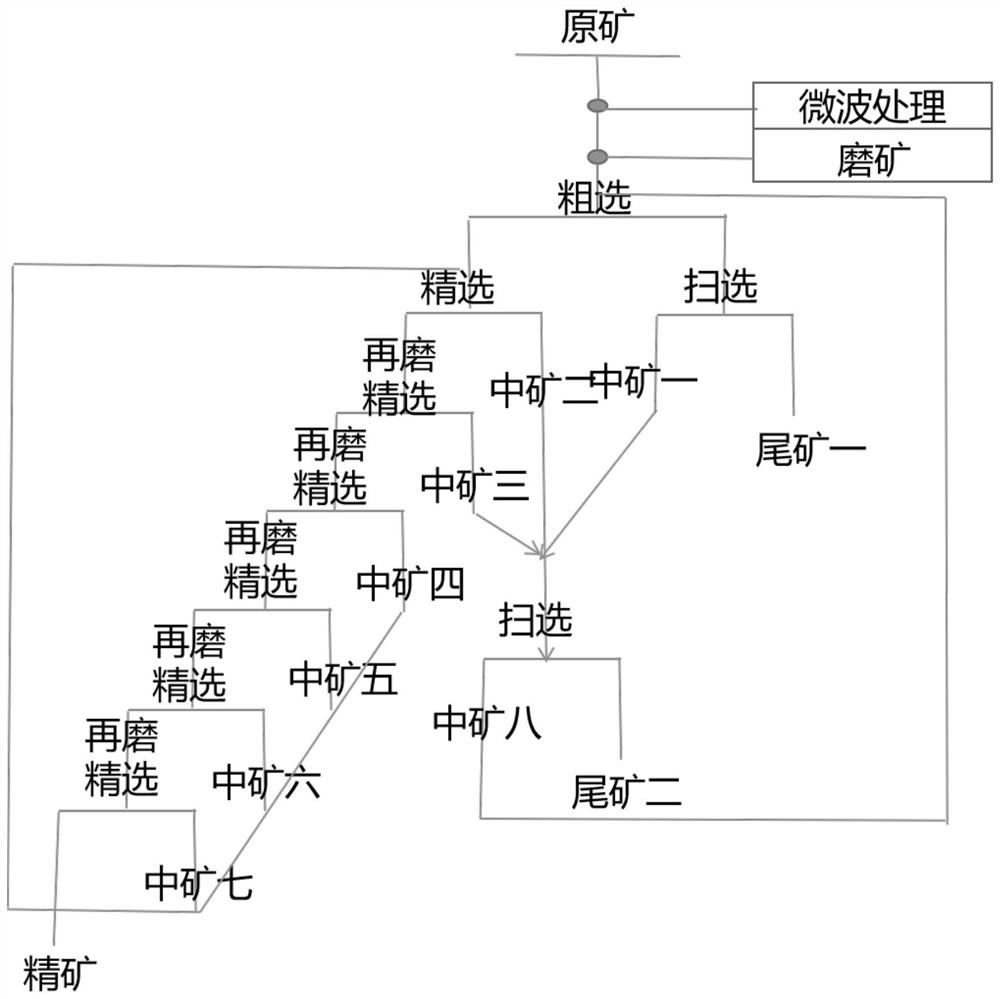

[0023] Embodiment 1: a kind of microwave roasting pretreatment graphite ore strengthened flotation purification method (see figure 1 ),Specific steps are as follows:

[0024] (1) The low-grade fine-scale graphite ore is crushed to a particle size of 0.83-1.7mm to obtain graphite ore particle A, and graphite ore particle A is pretreated by microwave roasting for 5 minutes to obtain graphite ore particle B; wherein the fixed carbon of low-grade fine-scale graphite ore The content is 5.63%, the main components of impurities are oxides of elements such as Fe, Al, Ca, Mg, Si, etc., and the water content is below 1%;

[0025] (2) step (1) graphite ore particle B is carried out wet grinding treatment to particle size not more than 0.075mm and accounts for 86% to obtain flotation graphite ore slurry;

[0026] (3) Step (2) Add 90g / t foaming agent A1 (No. 2 oil), 360g / t collector A2 (kerosene), 1000g / t regulator A3 (sodium silicate) in the flotation graphite pulp Sweeping, adding 45g / ...

Embodiment 2

[0029] Embodiment 2: a kind of microwave roasting pretreatment graphite ore enhanced flotation purification method (see figure 1 ),Specific steps are as follows:

[0030] (1) The low-grade fine-scale graphite ore is crushed to a particle size of 0.83-1.7mm to obtain graphite ore particle A, and graphite ore particle A is pretreated by microwave roasting for 10 minutes to obtain graphite ore particle B; wherein the fixed carbon of low-grade fine-scale graphite ore The content is 5.63%, the main components of impurities are oxides of elements such as Fe, Al, Ca, Mg, Si, etc., and the water content is below 1%;

[0031] (2) step (1) graphite ore particle B is carried out wet grinding treatment to particle size and is not more than 0.075mm and accounts for 84% and obtains flotation graphite ore slurry;

[0032](3) Step (2) Add 60g / t foaming agent A1 (No. 2 oil), 300g / t collector A2 (kerosene), 1200g / t regulator A3 (sodium silicate) in the flotation graphite pulp Sweeping, adding...

Embodiment 3

[0035] Embodiment 3: a kind of microwave roasting pretreatment graphite ore strengthened flotation purification method (see figure 1 ),Specific steps are as follows:

[0036] (1) The low-grade fine-scale graphite ore is crushed to a particle size of 0.83-1.7mm to obtain graphite ore particle A, and graphite ore particle A is pretreated by microwave roasting for 20 minutes to obtain graphite ore particle B; wherein the fixed carbon of low-grade fine-scale graphite ore The content is 5.63%, the main components of impurities are oxides of elements such as Fe, Al, Ca, Mg, Si, etc., and the water content is below 1%;

[0037] (2) step (1) graphite ore particle B is carried out wet grinding treatment to particle size and is not more than 0.075mm and accounts for 84% and obtains flotation graphite ore slurry;

[0038] (3) Step (2) Add 80g / t foaming agent A1 (No. 2 oil), 250g / t collector A2 (kerosene), 1100g / t regulator A3 (sodium silicate) in the flotation graphite pulp Sweeping, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com