A Central Cooling and Heating System for Canteens Based on Vapor Compression Heat Pump Technology

A heat pump technology and heating system technology, applied in the field of canteen centralized cooling and heating systems, can solve problems such as system performance degradation, heat extraction equipment corrosion, difficulty, etc., to shorten the investment return period, reduce initial investment costs, and reduce equipment. Equipped with effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

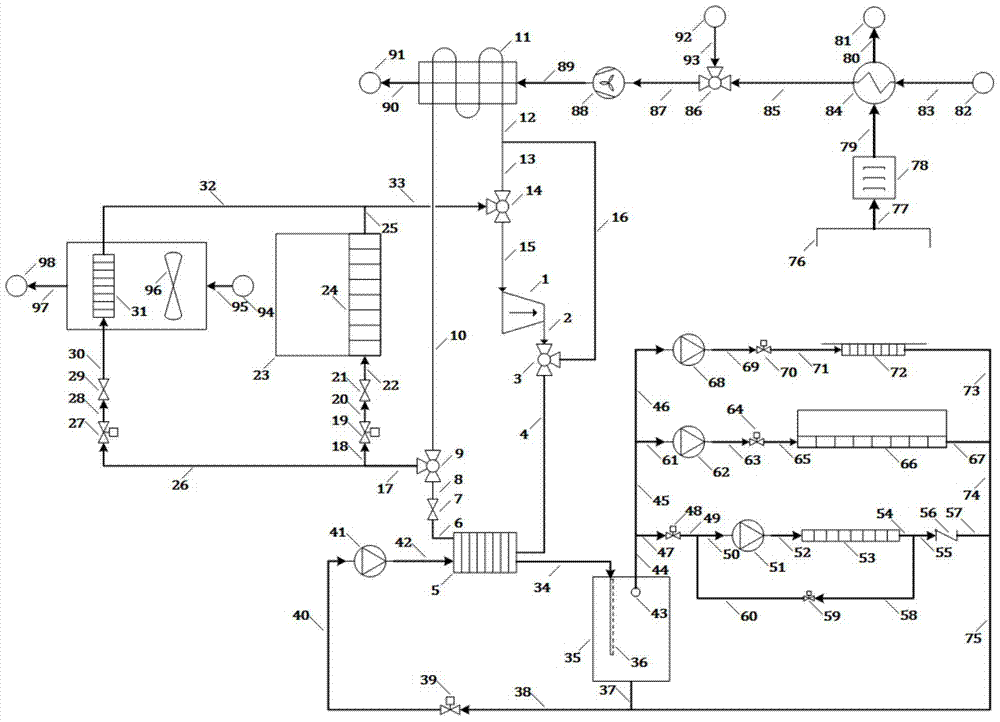

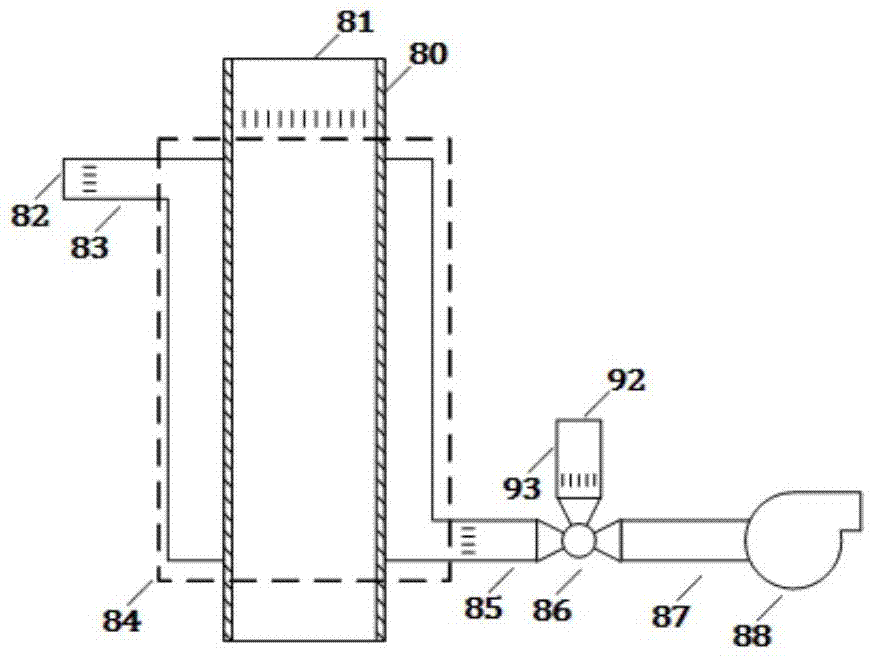

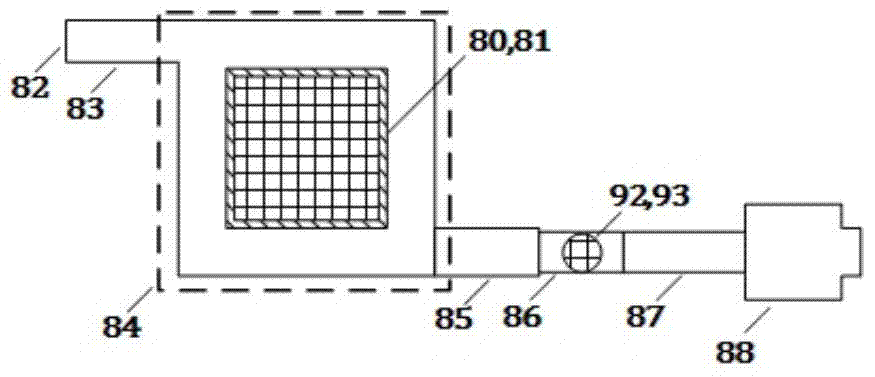

[0046] A central cooling and heating system for canteens based on vapor compression heat pump technology, its structure is as follows figure 1 As shown, it mainly includes compressor 1, outdoor heat exchanger 11, indoor condenser 5, canteen heating equipment, canteen cooling equipment, oil fume purifier 78, casing heat exchanger 84, refrigerator indoor evaporator 24, Air conditioner indoor evaporator 31 etc.

[0047] The inlet and outlet of the compressor 1 are respectively connected with the outdoor heat exchanger 11 and the indoor condenser 5 through the connecting pipe and the refrigerant three-way reversing valve; The three-way reversing valve of the agent is connected with the throttling device (which can be an electronic expansion valve) and the compressor 1, and the other part is connected with the DC fan and the exhaust port through the air connecting pipe; the indoor condenser 5 is provided with two connecting channels, one part The connecting pipe and the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com