Method for controlling a combustion and/or gasification device

A gasification device and combustion chamber technology, applied in the heat utilization of different solid fuels, the combustion of small-sized solid fuels and/or gasification devices, can solve laborious and expensive problems, achieve simple cost-effectiveness, and optimize air volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

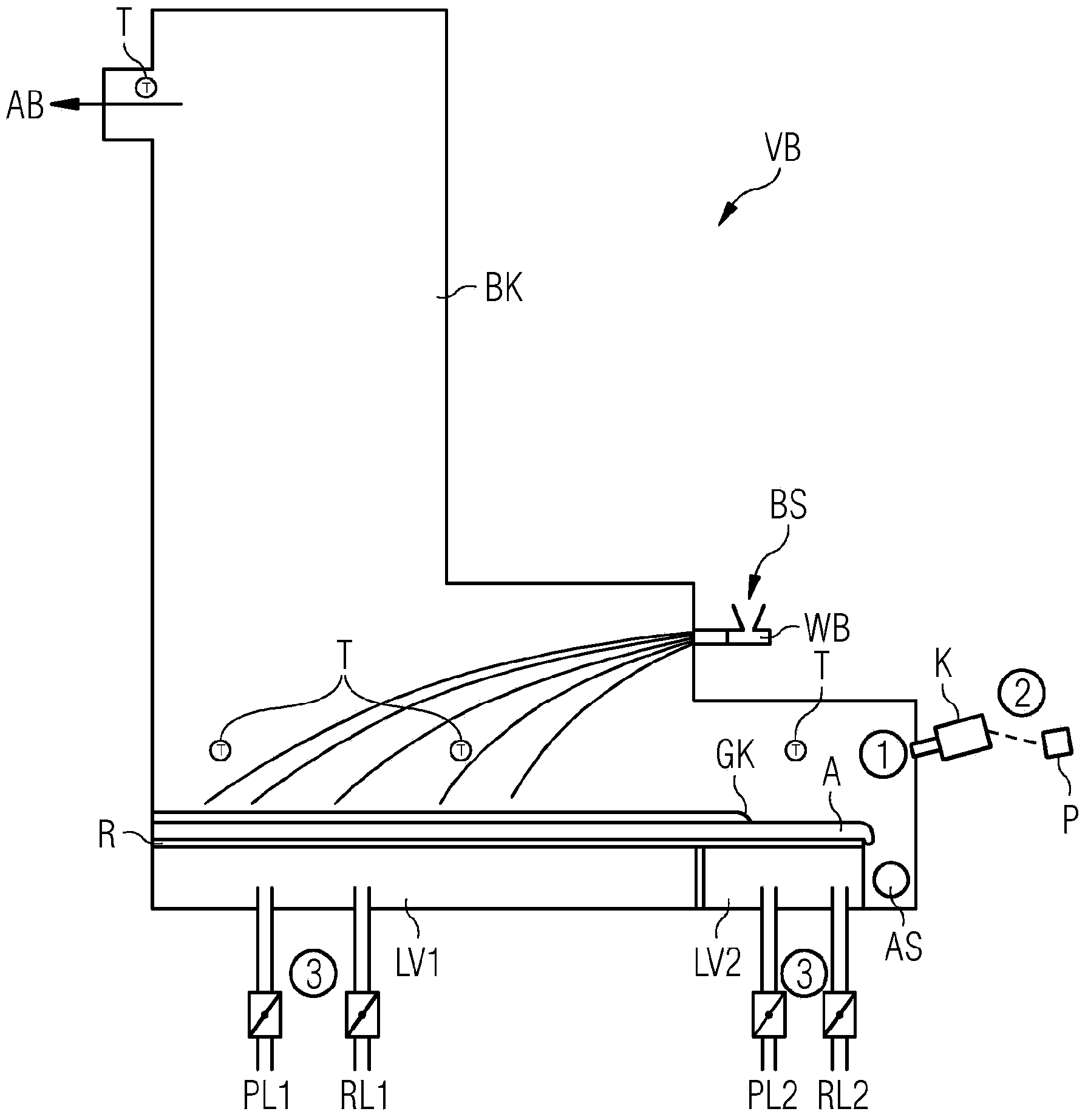

[0022] figure 1 An exemplary combustion or gasification plant VB for small-scale solid fuel BS is schematically shown, said plant VB being arranged for carrying out the method according to the invention. The plant VB comprises at least one combustion chamber BK and a grate R on which the combustion or gasification of the fuel BS is carried out. The fuel BS is injected into the combustion chamber BK for combustion or gasification by means of so-called throw-feeders WB and is thus evenly distributed over the grate R.

[0023] The fuel BS and ash A to be incinerated are located on the grate R which can be subdivided into at least two grate zones arranged in the longitudinal direction of the grate R. Such grate zones are in particular, for example, the so-called combustion or gasification zones, which occupy approximately 4 / 5 of the grate area, and the so-called burnout zones, which comprise approximately 1 / 5 of the grate zone. The combustion or gasification zone of the grate R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com