Combustion apparatus

a technology of combustion apparatus and combustion chamber, which is applied in the direction of combustion types, burners, hollow bar grates, etc., can solve the problems of increasing cost and reducing combustion efficiency, and achieve the effects of increasing the number of parts, increasing combustion efficiency, and increasing combustion velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Embodiments of the present invention will be explained with reference to the drawings.

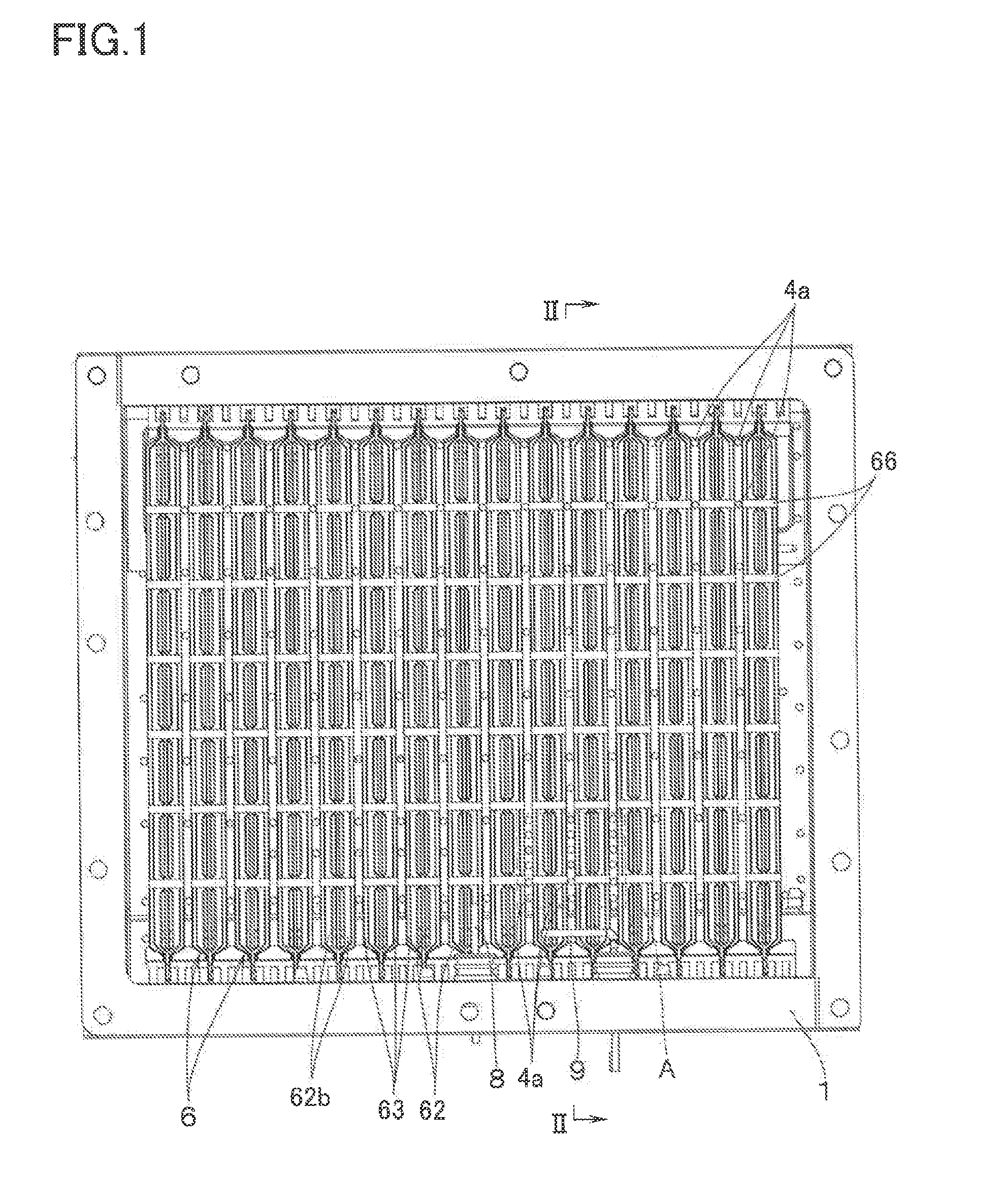

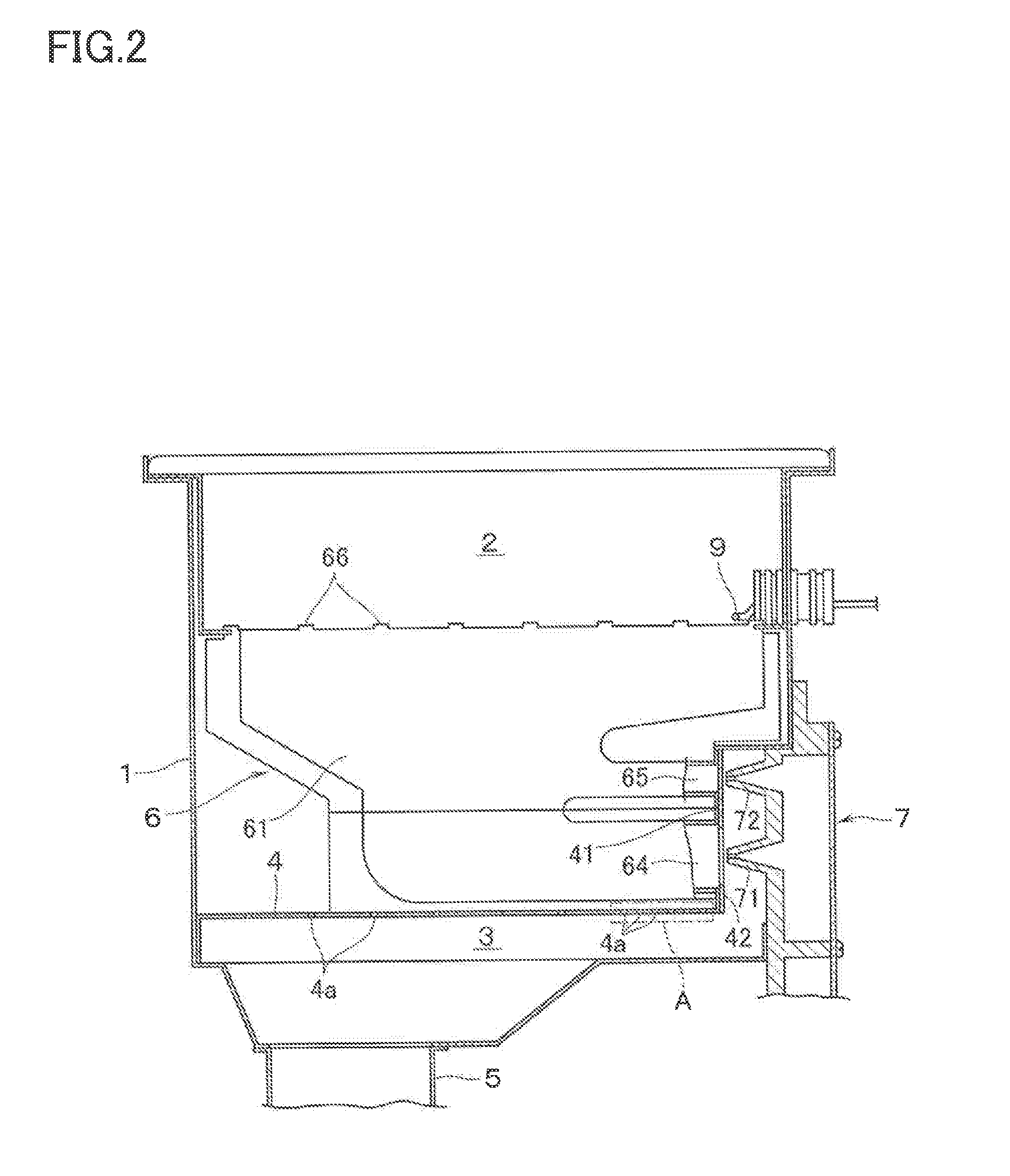

[0020]With reference to FIGS. 1 and 2, the combustion apparatus of the present embodiment includes a combustion housing 1. The upper surface of the combustion housing 1 is opened, and a heating object (not illustrated) such as a heat exchanger is placed on the combustion housing 1.

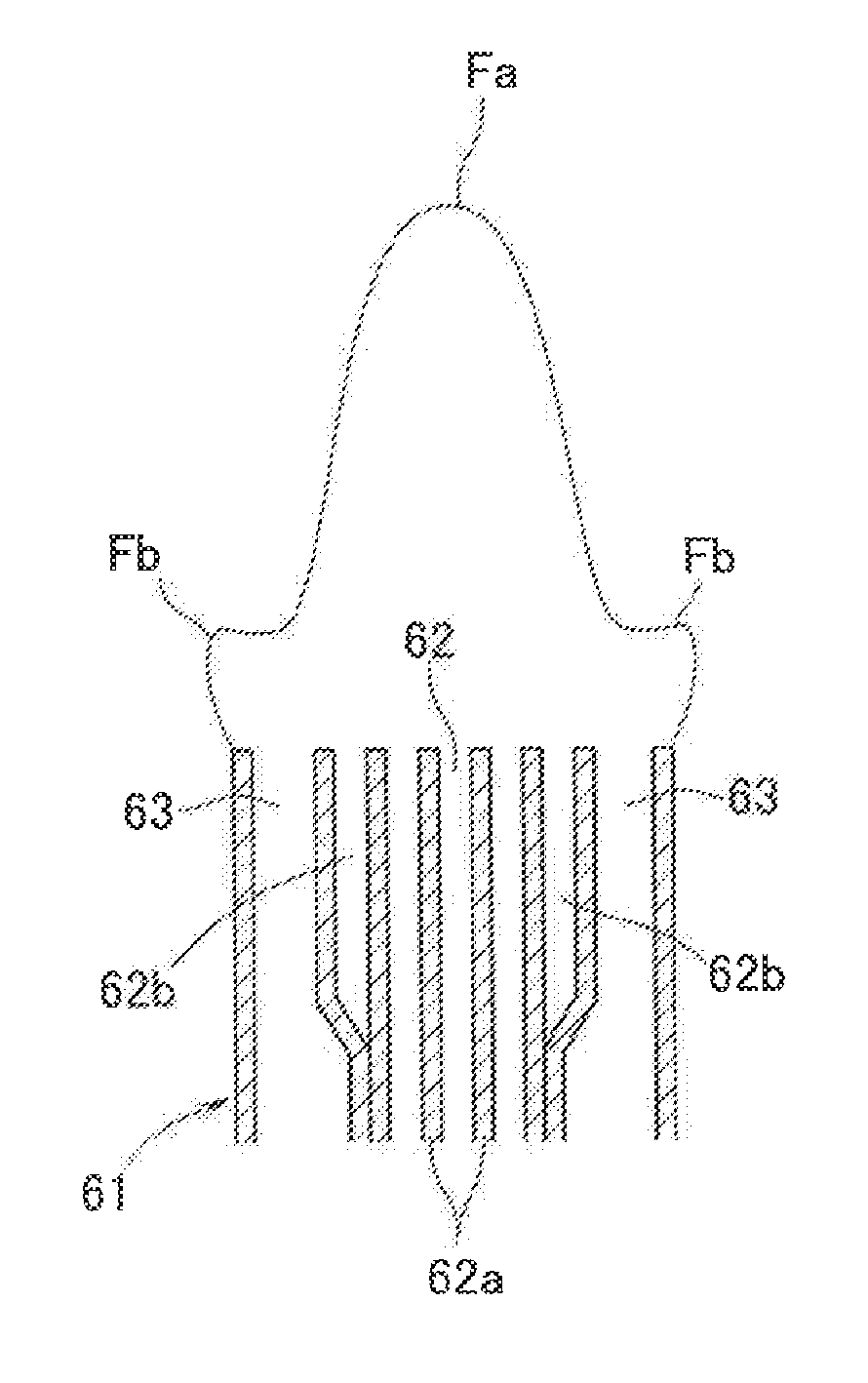

[0021]A partition plate 4 partitioning the space in the combustion housing 1 into a combustion chamber 2 and an air supply chamber 3 on the lower side of the combustion chamber 2 is provided in the combustion housing 1. A combustion fan (not illustrated) is connected to the bottom face of the air supply chamber 3 with a duct 5 put between them, and air is supplied from the combustion fan to the air supply chamber 3. A multiplicity of distributed holes 4a are formed in the partition plate 4 at the positions corresponding to the arrangement pitch portions of rich-lean burners 6, which will be described later. Then, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com