Hearth rotary furnace bar

A rotary furnace and hearth technology, applied in the field of stoves, can solve the problems of waste of resources, troubles, pollution of indoor air, etc., and achieve the effect of realizing home appliances

Inactive Publication Date: 2010-02-24

李仕清

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the grates in the common civil stoves are arranged longitudinally at the bottom of the furnace by several steel bars, and there is also a push-pull grate that cuts carbon slag through the front end of the grate, which is troublesome and pollutes the indoor air. Discharge, that is, the way of plane movement, some unburned coke is also discharged, resulting in waste of resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 2

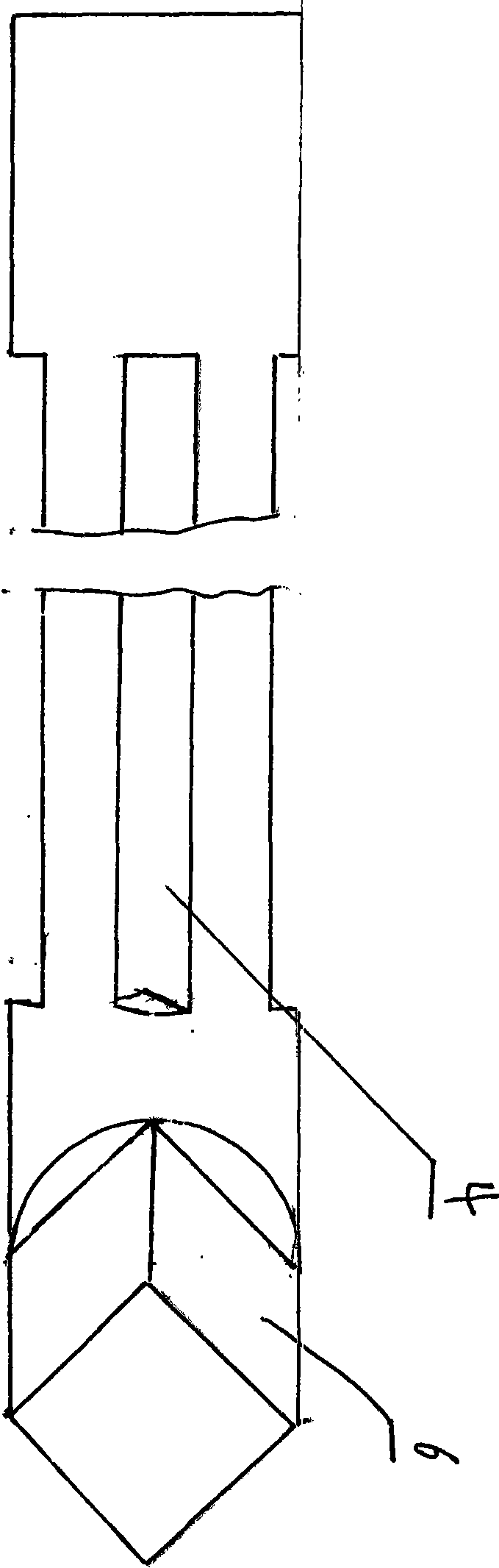

[0016] Embodiment 2 is different from Embodiment 1 in that a handle head 6 is provided at one end of the fire bar 1 , and the fire bar 1 can be rotated by putting a handle on the handle head 6 to shake and rotate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

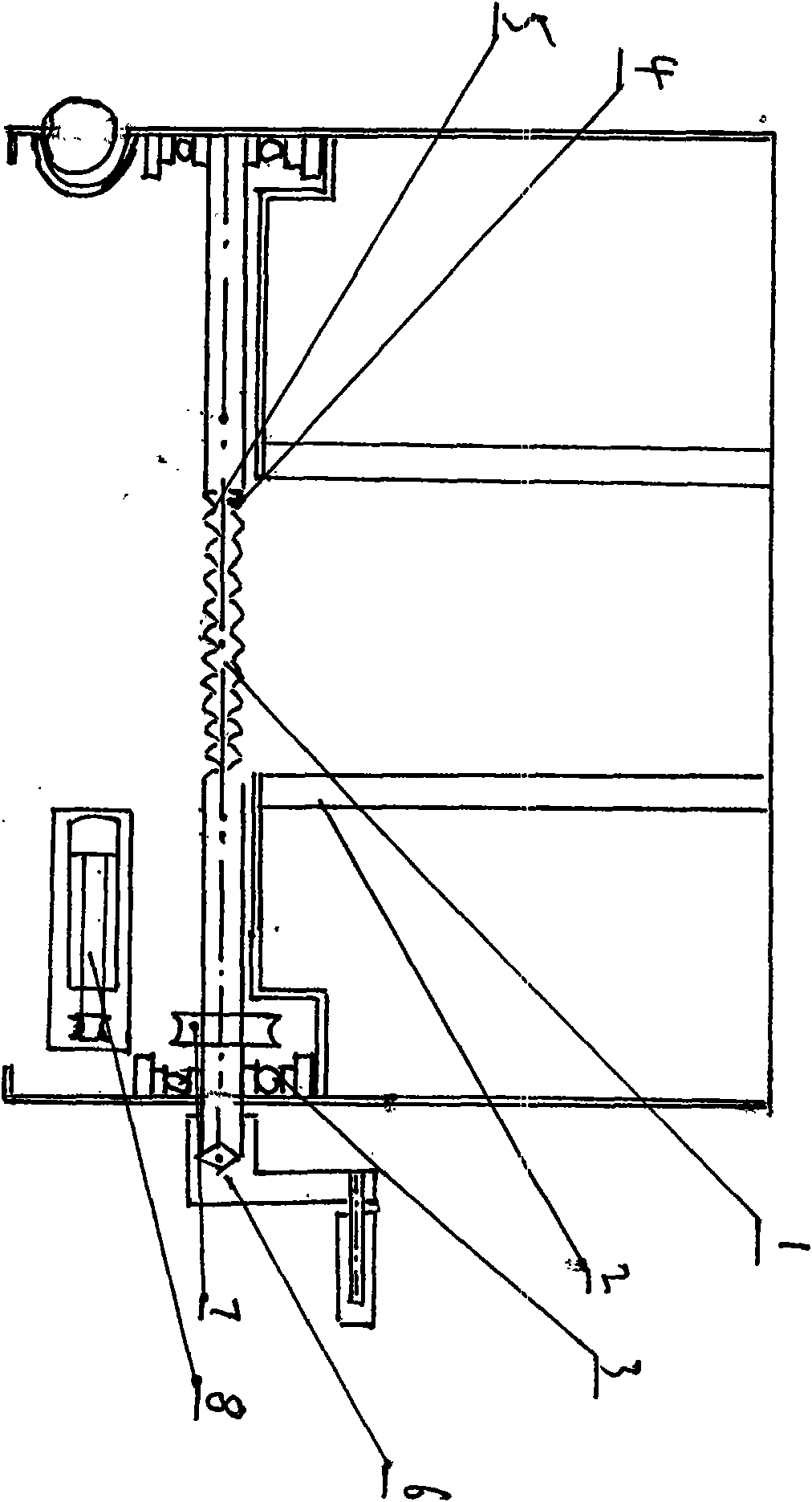

The invention relates to the stove and discloses a hearth rotary furnace bar. The furnace bar is connected with the hearth through a rotating device arranged on the inner wall of the bottom base of the hearth, one end of the furnace bar is driven by outside force to rotate, a groove or a damping tooth can be arranged at the part of the furnace bar which is opposite to the hearth, and handle is arranged on the furnace bar for manual rotation or the furnace bar can be also driven by a micromotor to rotate. The technical scheme of the invention is used to ensure that coal and other comburents canbe fully burnt, the operation is convenient and sanitary and the furnace can be used as furniture.

Description

technical field [0001] The invention relates to a stove, in particular to a stove bar for a stove. Background technique [0002] At present, the grates in the common civil stoves are arranged longitudinally at the bottom of the furnace by several steel bars, and there is also a push-pull grate that cuts carbon slag through the front end of the grate, which is troublesome and pollutes the indoor air. Exhaust, that is, the way of planar movement, some unburned coke is also discharged, resulting in waste of resources. Contents of the invention [0003] The present invention is proposed in view of the above problems, in order to provide a new type of furnace bar, which is convenient, hygienic, and easy to realize home appliances of stoves, and can fully burn coal and other combustibles when used in industrial boilers. , improve fuel utilization. [0004] In order to achieve the above object, the present invention adopts following technical scheme: [0005] 1. A furnace bar ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23H17/12F24B1/193

CPCF23H1/00F23H13/06F23H15/00F23H17/02F23H2700/004

Inventor 李仕清

Owner 李仕清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com