Non-stick pan coating layer and preparation method thereof

A non-stick pan and coating technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of easy falling off, human health hazards, hard food, etc., and achieve stable chemical properties and high friction coefficient Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

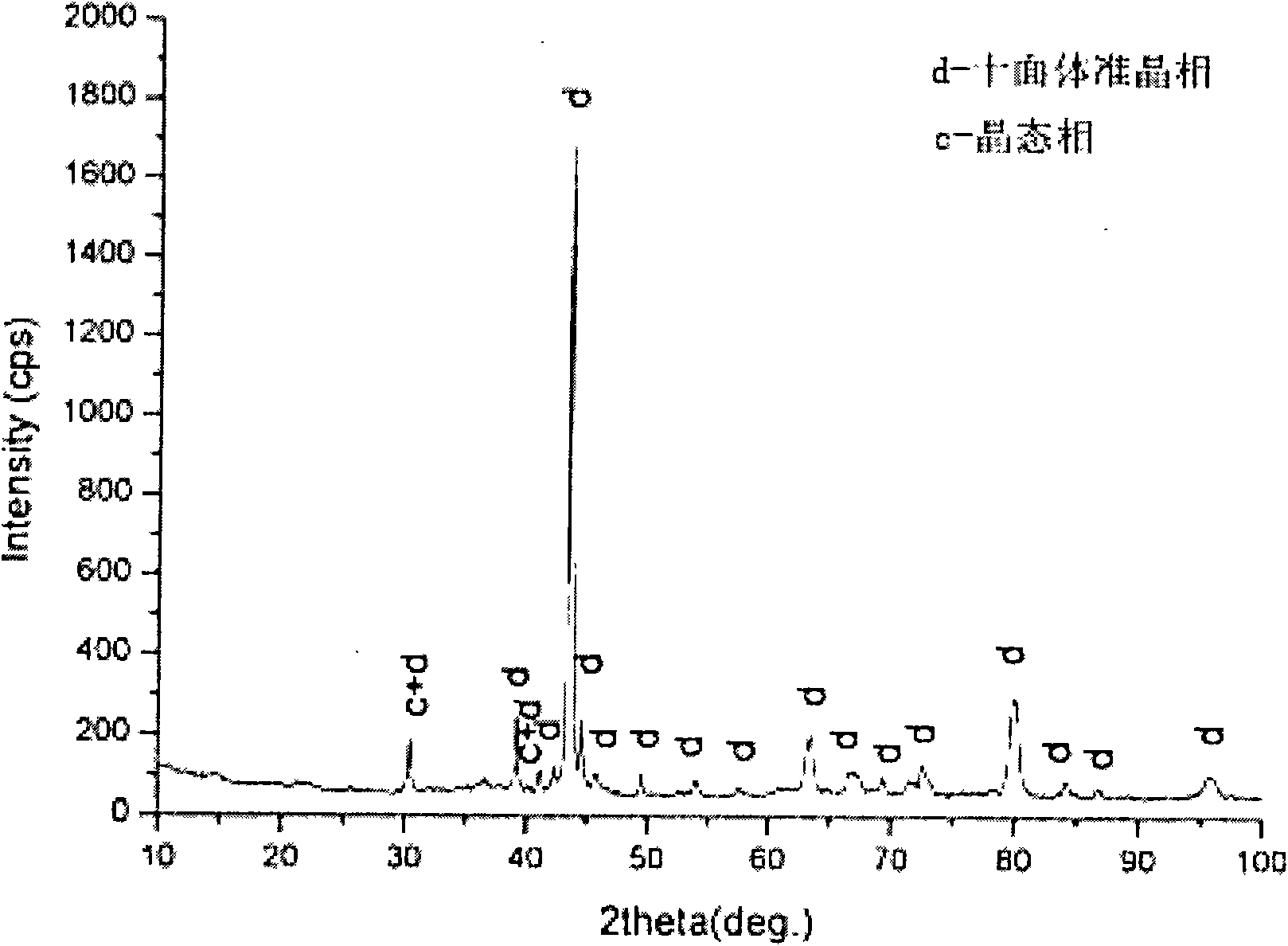

[0014] Aluminum, iron, copper, chromium and boron are prepared into alloy powder at 1050 DEG C with a spray device in the ratio of atomic ratio 71:9.9:8.5:10.5:0.1. Use plasma spraying equipment to spray the above alloy coating on the aluminum alloy pot substrate. The main parameters are: the main air flow rate is 65L / min, the secondary air flow rate is 25L / min, the arc current is 565A, the arc voltage is 49V, and the powder feeding capacity It is 11.5g / min. When spraying, the aluminum alloy pot base is preheated to about 500°C. figure 1 It shows that the alloy powder prepared at this ratio is mainly quasicrystalline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com