Preparation method of ultrathin fluorinated graphene composite lubrication film

A fluorinated graphene, lubricating film technology, applied in adhesive additives, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as lubrication occasions that are not suitable for extensive and large-scale applications, limited size, and complex equipment. Achieve the effect of good application prospects, low adhesion, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of ultra-thin fluorinated graphene composite lubricating film, comprising the following steps:

[0037] (i) Preparation of fluorinated graphene dispersion

[0038] Add the hydroxide into the organic solvent and stir. During the stirring process, add fluorinated graphite powder, ultrasonically disperse the mixture until it is uniform, and then put it in an oven to dry until the solvent evaporates; heat the obtained mixture at 180°C for 4h, Then let it stand at room temperature, add the reaction product into water to stir and disperse, then filter under reduced pressure, wash to neutrality, and dry to obtain a black powder; redisperse the black powder in a water-alcohol mixed solvent, ultrasonicate for 5h, and ultrasonically After the obtained dispersion is centrifuged, the supernatant obtained is the fluorinated graphene dispersion;

[0039] (ii) Preparation of polydopamine adhesive-buffer layer

[0040] The single crystal silicon substrate is clea...

Embodiment 1

[0055] A preparation method of ultra-thin fluorinated graphene composite lubricating film, comprising the following steps:

[0056] (i) Preparation of fluorinated graphene dispersion

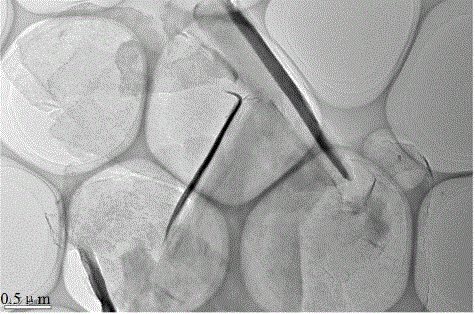

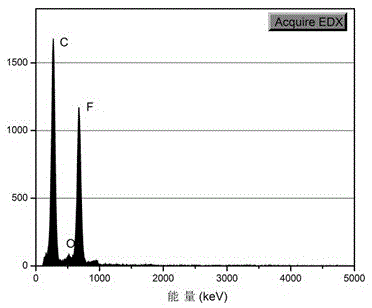

[0057] Dissolve 64.52 mg of sodium hydroxide and 90.32 mg of potassium hydroxide in 5 mL of absolute ethanol, stir at room temperature until completely dissolved, add 200 mg of graphite fluoride with a particle size of 4 μm during the stirring process, and ultrasonically disperse at 100 W for 30 min , then the dispersion was evaporated and dried at 50°C until the solvent evaporated; the uniformly mixed powder was heated at 180°C for 4 hours, and then allowed to stand at room temperature, then added with ultrapure water to stir and disperse, and filtered under reduced pressure and washed to Neutral pH, dry at 40°C to get a black powder, redisperse the above powder in a water-ethanol mixed solvent with a volume ratio of 1:1, and ultrasonically treat it at 100W for 5 hours, and the supernatant obta...

Embodiment 2

[0064] A preparation method of ultra-thin fluorinated graphene composite lubricating film, comprising the following steps:

[0065] (i) Preparation of fluorinated graphene dispersion

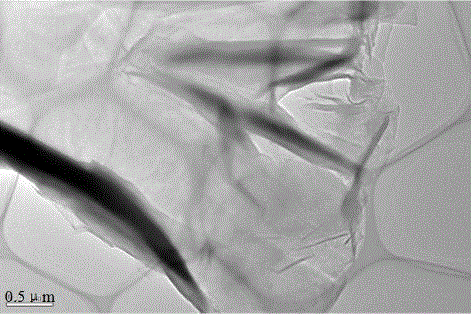

[0066] Dissolve 64.52mg of sodium hydroxide and 90.32mg of potassium hydroxide in 5mL of anhydrous methanol, stir at room temperature until completely dissolved, add 200mg of graphite fluoride with a particle size of 5μm during the stirring process, and ultrasonically disperse at 200W for 30min , then the dispersion was evaporated and dried at 50°C until the solvent evaporated; the uniformly mixed powder was heated at 180°C for 4 hours, and then allowed to stand at room temperature, then added with ultrapure water to stir and disperse, and filtered under reduced pressure and washed to Neutral pH, dry at 50°C to get a black powder, redisperse the above powder in a water-ethanol mixed solvent with a volume ratio of 1:1, ultrasonically treat it at 200W for 5 hours, and the supernatant obtained afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com