Bonded metal components having uniform thermal conductivity characteristics and method of making same

A metal, uniform technology, applied in the field of bonding metal components with uniform heat transfer characteristics and their manufacturing, which can solve the problems of thermal warpage, reducing the heat transfer efficiency and uniformity of the intermediate surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

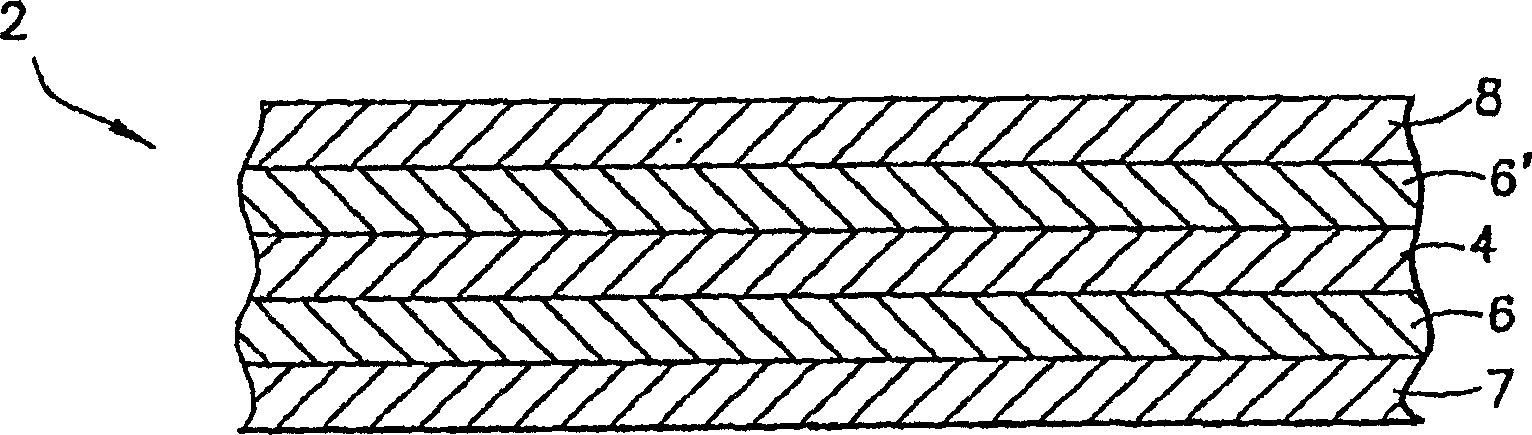

[0014] Referring now to the accompanying drawings, figure 1 A preferred embodiment of the bonded metal composite sheet 2 of the invention is shown schematically in cross-section. The composite sheet 2 is a multilayer rolled structure comprising a layer 4 of a material with a lower thermal conductivity than the other metal layers in the composite sheet 2 . A preferred material for the lower thermal conductivity layer 4 is titanium or a titanium alloy because of its rather low thermal conductivity compared to aluminium, in addition to its lower weight compared to aluminium. Stainless steel has a thermal conductivity similar to that of titanium and can be used for layer 4 . Stainless steel is less expensive than titanium, but is heavier, adding to the weight of the cookware. exist figure 1 In the composite sheet 2, the titanium layer 4 is calendered between the aluminum layers 6 and 6' on both sides. The aluminum layers 6 and 6' comprise 1100 series pure aluminum, or the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com