Electric automobile body frame bottom structure

A body frame and bottom structure technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of stability, safety impact, encroachment on power battery space, occupied space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

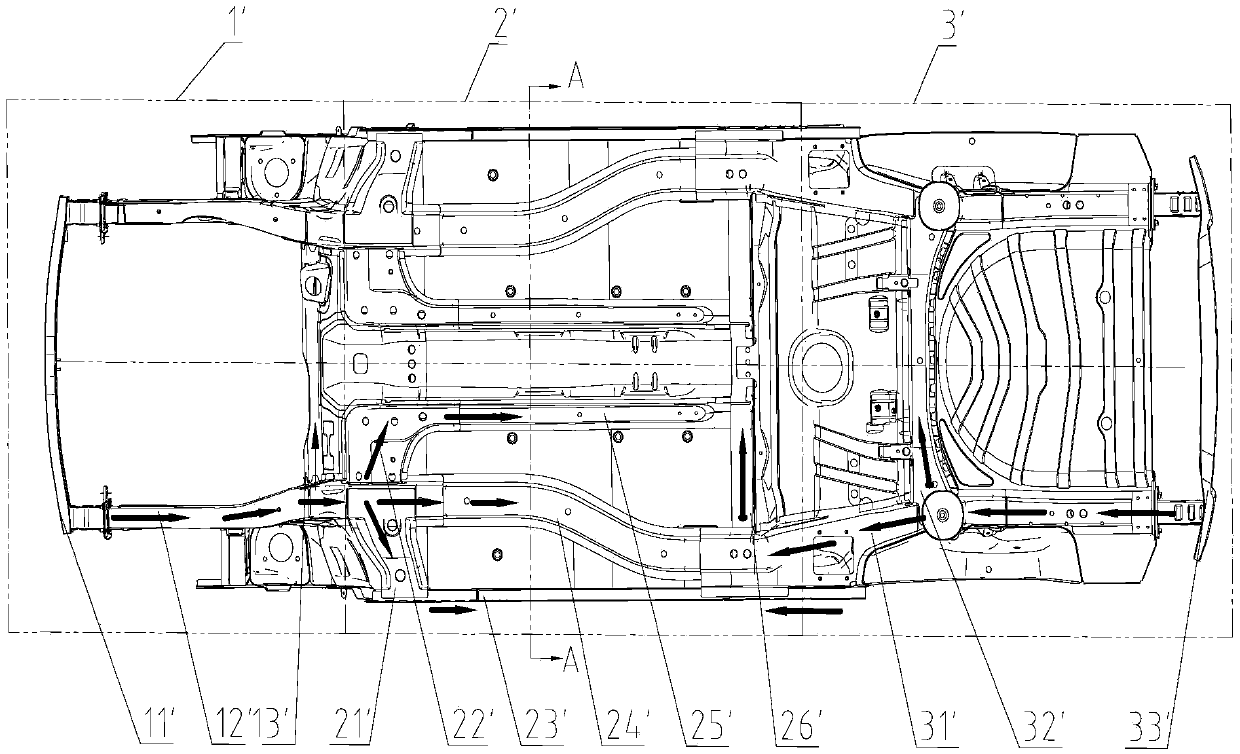

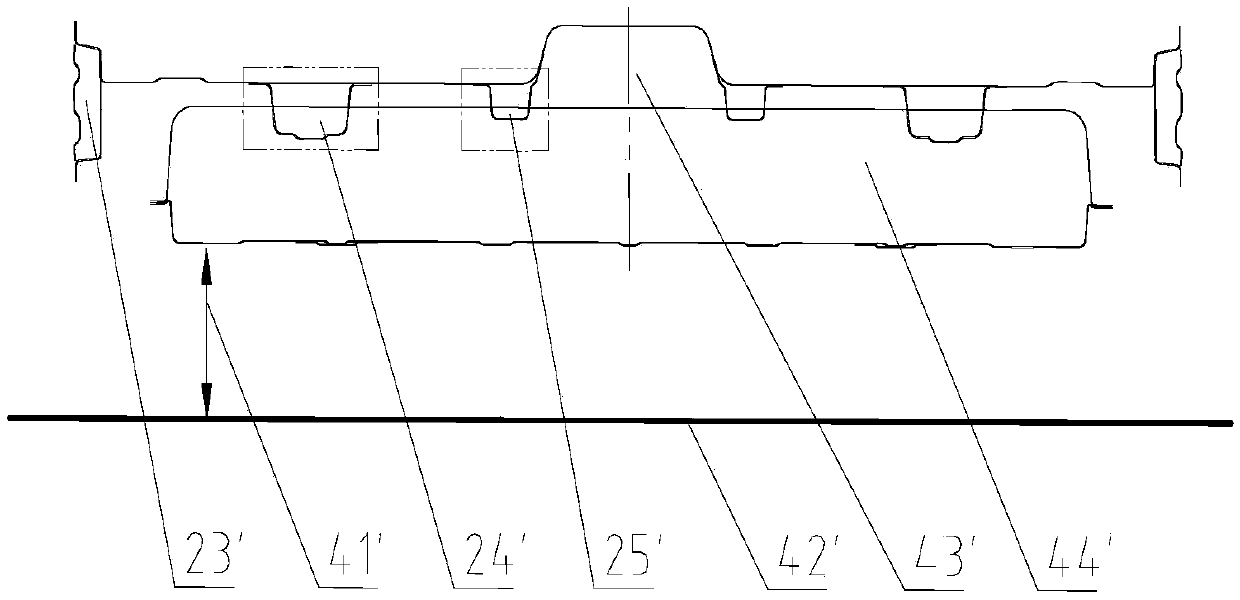

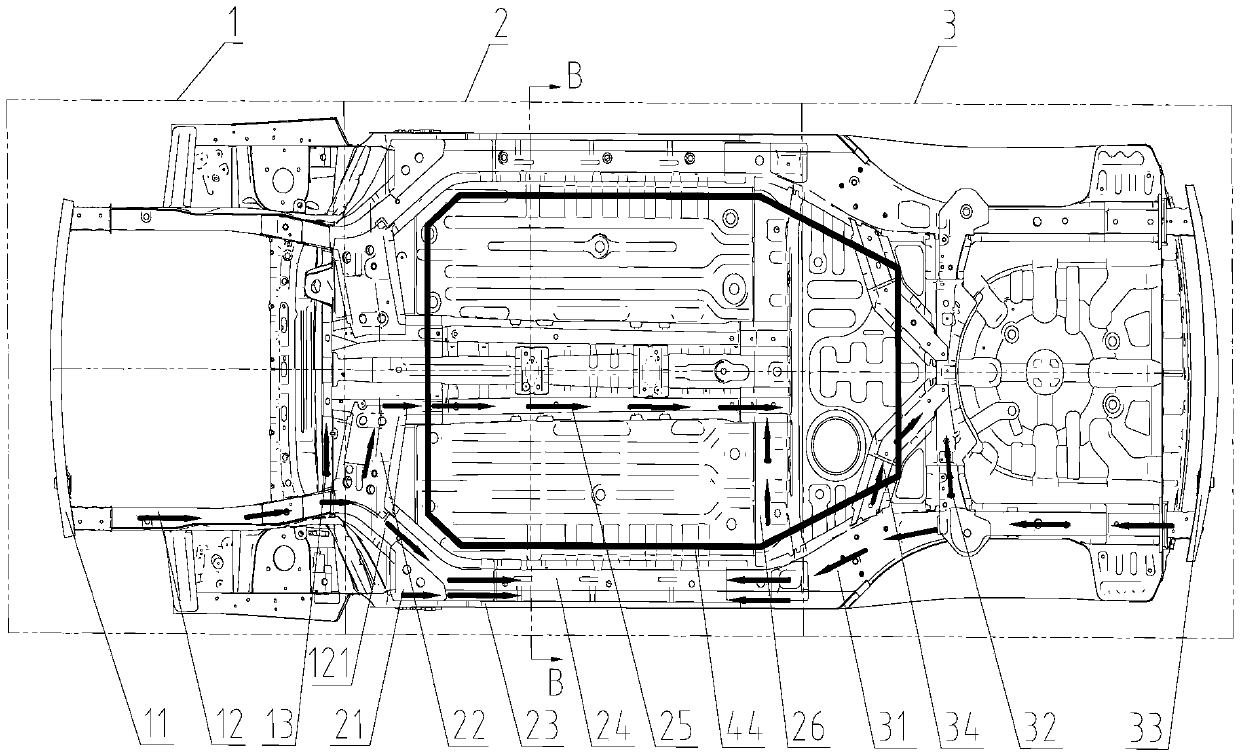

[0034] Such as image 3 Shown is a structural schematic diagram of the bottom structure of a body frame of an electric vehicle in the present invention, including: a cabin assembly 1, a front floor assembly 2, and a rear floor assembly 3 arranged in sequence, and the front floor assembly 2 includes: a front The floor 45 forms a longitudinal mid-floor passage cavity 43 in the center of the floor, is accommodated in the mid-floor passage cavity 43 and is symmetrically arranged in two of the two sides of the central axis of the mid-floor passage cavity 43 . The channel longitudinal beam 25, the power battery 44 arranged under the channel cavity 43 in the floor, and the two front floor longitudinal beams 24 and two door sills arranged symmetrically on both sides of the power battery 44 and sequentially arranged from the inside to the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com