Method for extracting resveratrol from Polygonum cuspidatum

A technology of resveratrol and Polygonum cuspidatum, which is applied in the field of extracting resveratrol, can solve the problems of resveratrol loss, achieve high extraction efficiency, easy operation, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

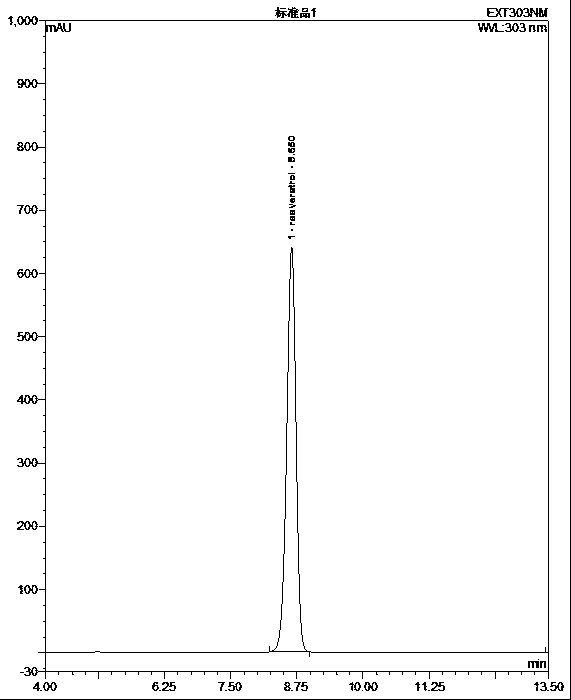

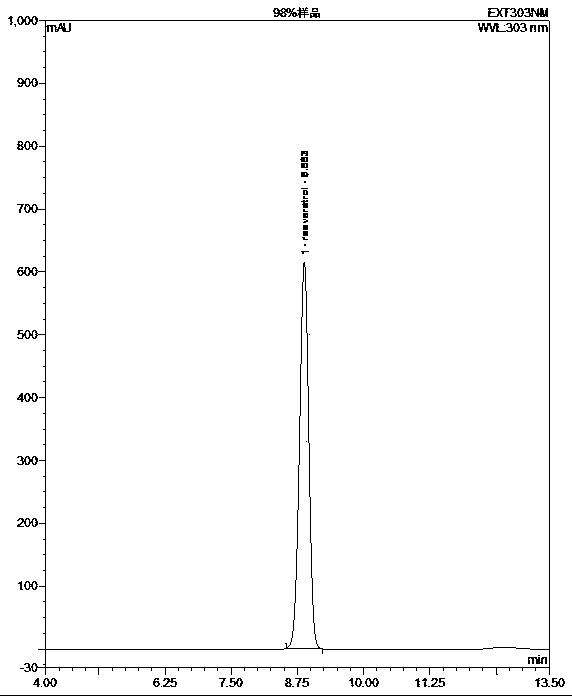

Image

Examples

Embodiment 1

[0020] Crush 100g of dried Polygonum cuspidatum to 50 mesh, and irradiate with ultraviolet rays for 60 minutes to inactivate the enzyme. Then add 200g of water to the coarse powder of Polygonum cuspidatum, adjust the pH to 5, then add 0.2g of cellulase, enzymolyze at 45°C for 4h, and ultrasonically treat the enzymolyzed solution for 10min every 30min, the ultrasonic frequency is 80kHz, and the ultrasonic power is 200W , to obtain enzymolysis solution I; add 75% ethanol to enzymolysis solution I, extract 2 to 3 times, combine the extracts and filter, and concentrate the filtrate to obtain thick paste extract I; Mix 10 times the volume of water and 0.2% of its mass of cellulase, stir, enzymolyze at 45°C for 4 hours, and ultrasonically treat the enzymatic solution for 10 minutes every 30 minutes to obtain enzymatic solution II; add 75 % ethanol, extract 2 to 3 times, combine the extracts and filter, and concentrate the filtrate into a thick paste extract II; use macroporous adsor...

Embodiment 2

[0022] Crush 500g of dried Polygonum cuspidatum to 60 mesh, and irradiate with ultraviolet rays for 60 minutes to inactivate the enzyme. Then add 1L of water to the coarse powder of Polygonum cuspidatum, adjust the pH=5, then add *1.2g cellulase, enzymolyze at 50°C for 4 hours, and ultrasonically treat the enzymolyzed solution for 10min every 30min, the ultrasonic frequency is 60kHz, and the ultrasonic power is 300W to obtain enzymatic solution I; add 80% ethanol to the enzymatic solution I, extract 2 to 3 times, combine the extracts and filter, and concentrate the filtrate to obtain thick paste extract I; Mix 10 times its volume of water and 0.2% of its mass of β-glucosidase, stir, enzymolyze at 50°C for 4 hours, and ultrasonically treat the enzymatic solution for 10 minutes every 30 minutes to obtain enzymatic solution II; Add 80% ethanol to the mixture, extract 2 to 3 times, combine the extracts and filter, and concentrate the filtrate to obtain thick paste extract II; use ...

Embodiment 3

[0024] Crush 5000g of dried Polygonum cuspidatum to 60 mesh, and irradiate with ultraviolet rays for 60 minutes to inactivate the enzyme. Then add 8.5L of water to the coarse powder of Polygonum cuspidatum, adjust the pH=5, then add 12g of cellulase, enzymolyze at 50°C for 4h, and ultrasonically treat the enzymolyzate for 10min every 30min, the ultrasonic frequency is 80kHz, and the ultrasonic power is 200W , to obtain enzymatic solution I; add 90% ethanol to the enzymatic solution I, extract 2 to 3 times, combine the extracts and filter, and concentrate the filtrate to obtain a thick paste extract I; add other extracts to the thick paste extract 10 times the volume of water, then add 0.3% of the mass of the mixture of β-glucosidase and cellulase (wherein the ratio of β-glucosidase to cellulase mass is 2:1), stir, at 45 ℃ Under the enzymatic hydrolysis for 4 hours, the enzymatic hydrolysis solution was ultrasonically treated for 10 minutes every 30 minutes to obtain the enzyma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com