Casing pipe combination type rebar connecting device and method

A technology of connecting device and connecting method, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of unrealizable and unrealized steel bar connection, and achieve the effect of increasing firmness and firmness of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a casing combined steel bar connection device and a connection method thereof.

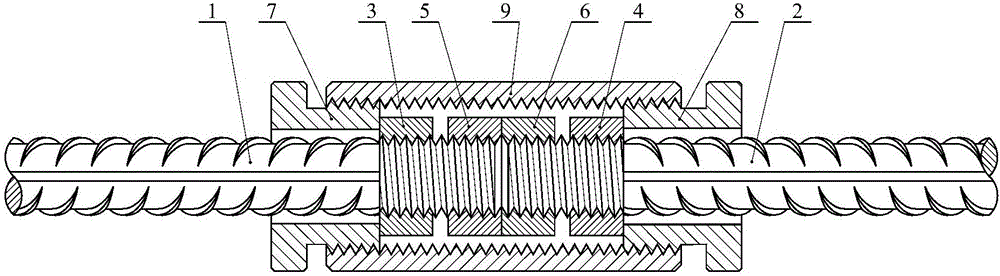

[0072] refer to figure 1 As shown, the specific connection method, structure, characteristics and functions of a casing combined steel bar connection method and processing device proposed in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0073] The present invention is a kind of method applicable to steel bar connection in construction engineering, and it mainly comprises following connection steps:

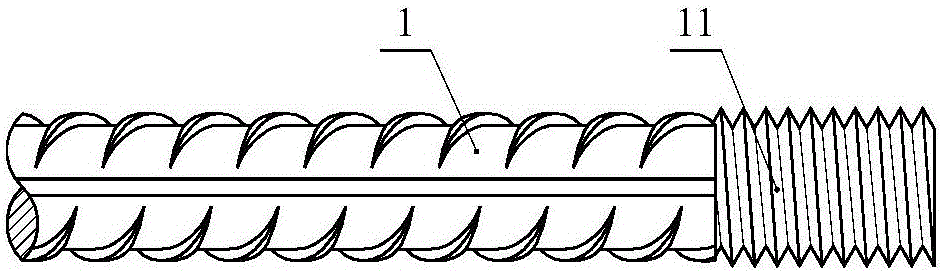

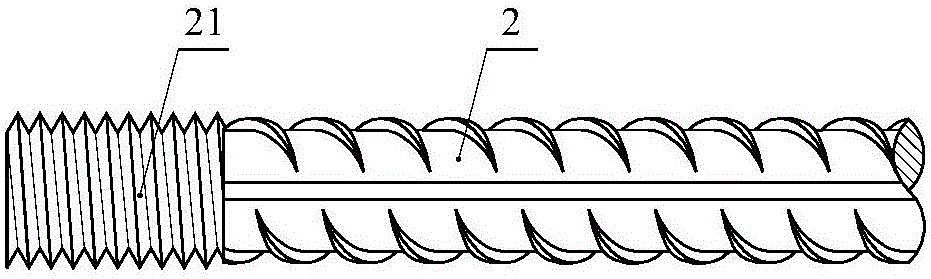

[0074] The connecting device is respectively equipped with: connected steel bar 1, connected steel bar 2, tension screw sleeve 3, tension screw sleeve 4, pressure screw sleeve 5, pressure screw sleeve 6, locking screw sleeve 7, locking screw sleeve Screw sleeve 8 and sleeve pipe 9 are formed.

[0075] A locking screw sleeve 7 with an external thread is inserted on the connected steel bar 1, and the external th...

Embodiment 2

[0086] The purpose of the present invention can also be further implemented through the following technical solutions.

[0087] refer to Figure 11 As shown, the specific connection method, structure, characteristics and functions of another casing combined steel bar connection method and processing device proposed in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0088] The present invention is a kind of method applicable to steel bar connection in construction engineering, and it mainly comprises following connection steps:

[0089] The connecting device is respectively equipped with: the connected steel bar, the connected steel bar, the tension screw sleeve, the tension screw sleeve, the pressure bearing screw sleeve, the pressure bearing screw sleeve, the locking screw sleeve and the casing. The inside of the casing in this embodiment is stepped, such as Figure 12 As shown, the lock nut in this embodiment is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com