Candy-shaped metamaterial wave absorber

A wave absorber and metamaterial technology, applied in antennas, electrical components, magnetic field/electric field shielding, etc., can solve the problems of narrow operating frequency band, low absorption rate, unstable electromagnetic wave absorption rate, etc., and achieve wide operating frequency band and absorption rate High, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

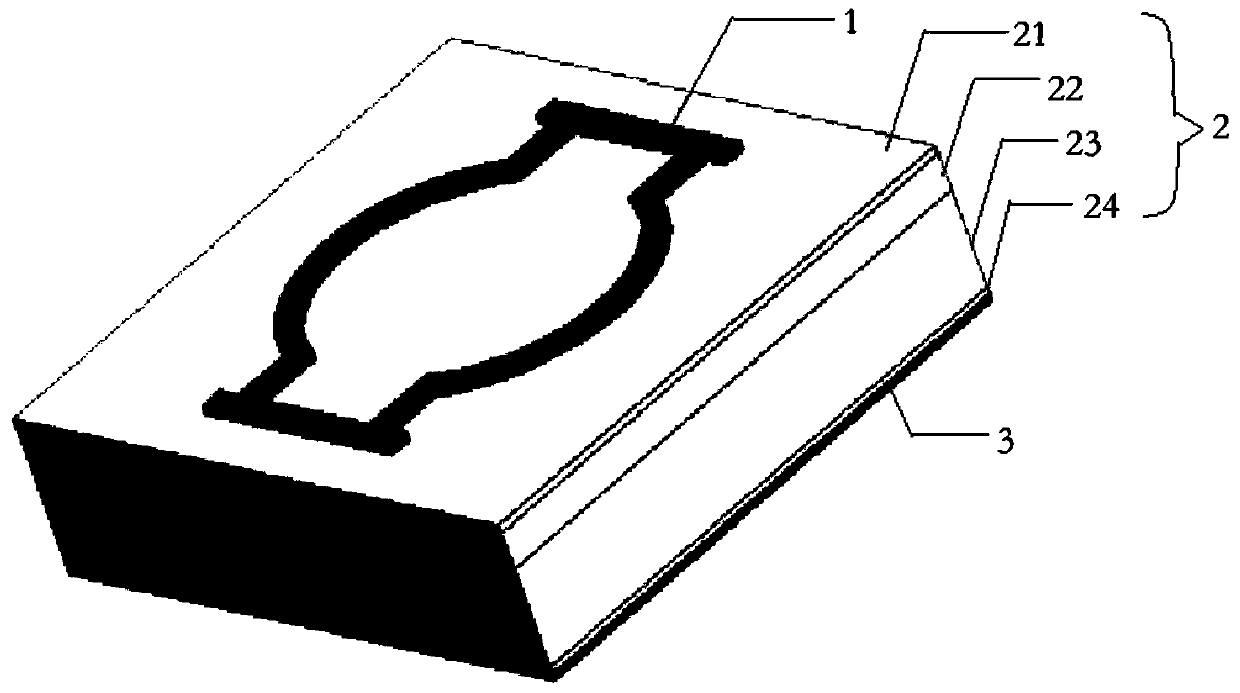

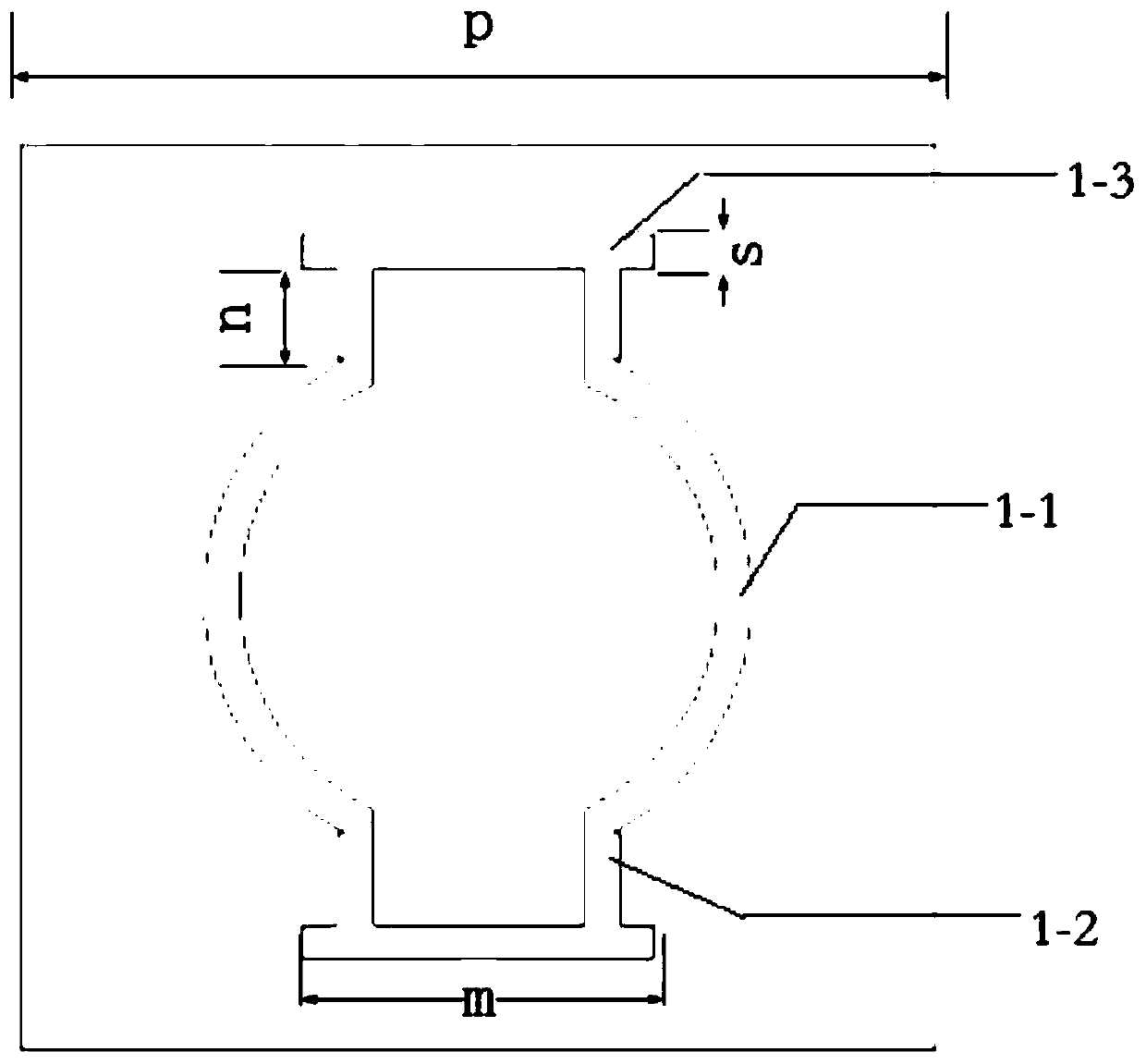

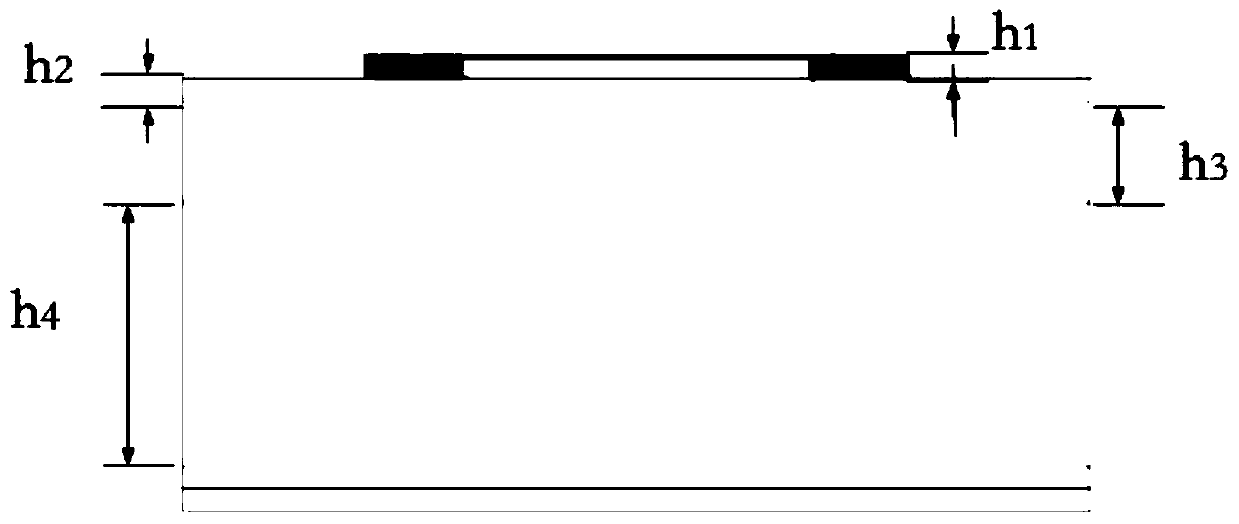

[0026] A candy-shaped metamaterial wave absorber is an infinite periodic structure, including N*M wave absorbing units connected in sequence, and the structural size parameters of each layer of each wave absorbing unit are as follows: the side length p of the wave absorbing unit =13mm, the thickness h of the candy-shaped resistive film 1 1 =0.175mm, the square resistance value R of the candy-shaped resistive film 1=100Ω. The line width of the candy-shaped resistive film 1 is s=0.5mm, the outer diameter of the arc 1-1 is r=3.9mm, the length of the short arm 1-2 is n=1.3mm, and the length of the long arm 1-3 is m=5mm. The thickness of the first PET layer 21 and the second PET layer 24 is the same, the thickness h 2 =0.175mm, thickness h of FR-4 layer 22 3 =0.85mm, the thickness h of the PMMA layer 23 4 = 2.25 mm.

[0027] The simulation results are as Figure 4 , Figure 5 and Figure 6 As shown, the advantages of the candy-type metamaterial wave absorber of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com