Anchor cable bundle supporting device and roadway supporting method

A technology of support device and roadway support, which can be used in earth-moving drilling, installation of bolts, mining equipment, etc., can solve the problems of high roof pressure, difficult support, large deformation of roadway, etc., so as to increase the anchorage length, improve the Support effect, ensure the effect of anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

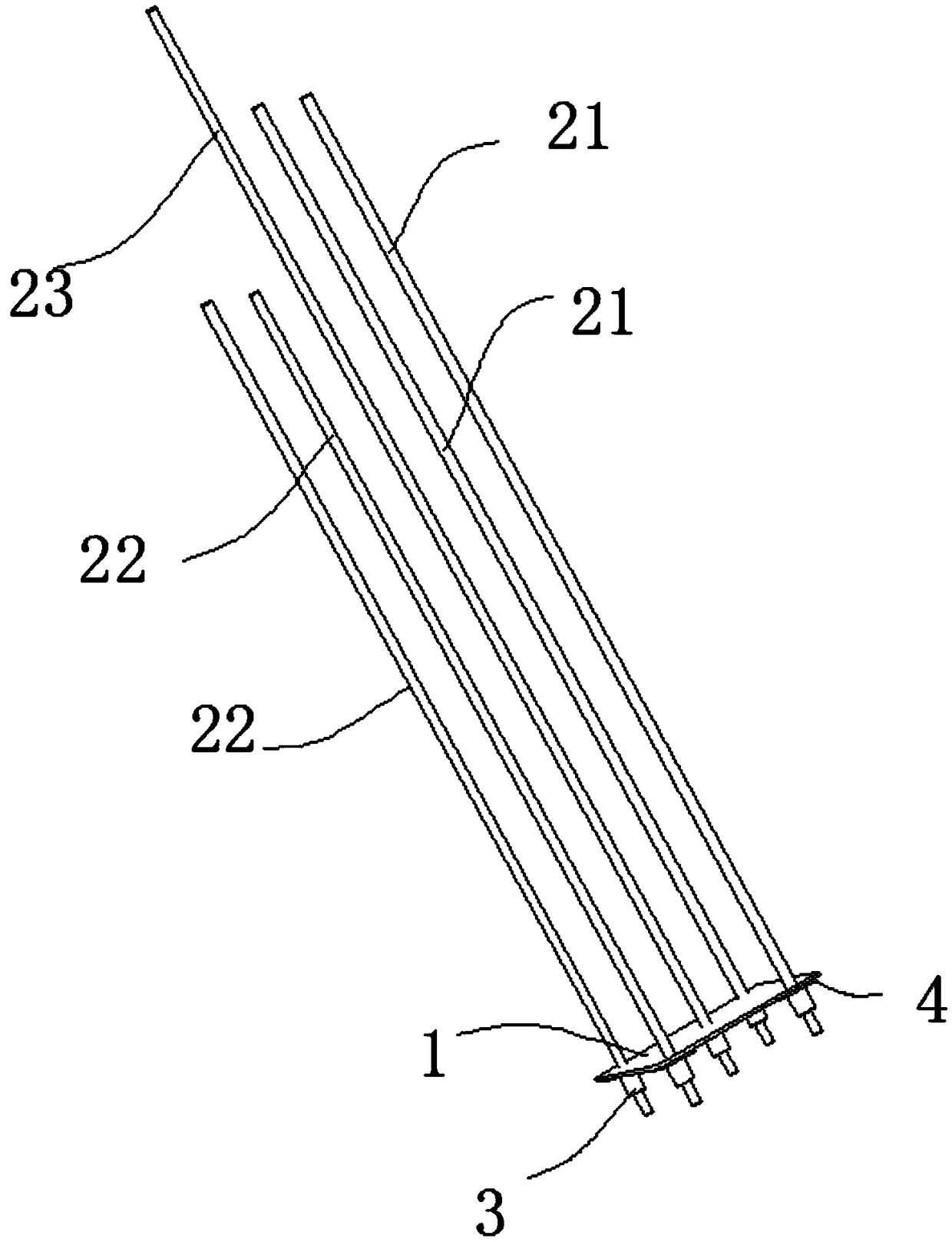

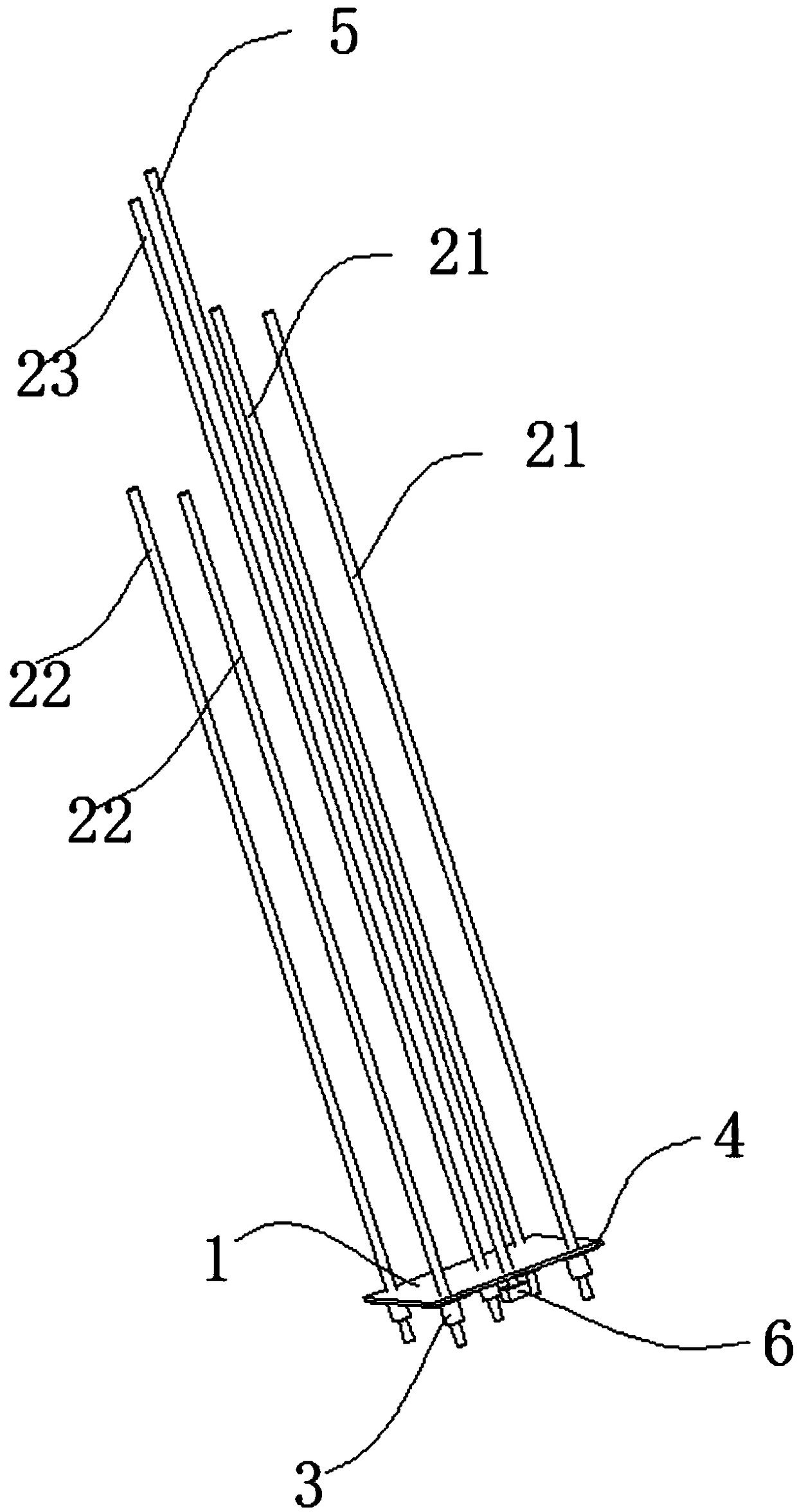

[0031] combined with figure 1 , a support device for anchor cables in the present invention, comprising a tray 1, five anchor cables and five locks 3 respectively corresponding to the five anchor cables, the five anchor cables are respectively two first anchor cables 21, two A second anchor cable 22 and a third anchor cable 23, the lengths of the first anchor cable 21, the second anchor cable 22 and the third anchor cable 23 are respectively a, b and c, c>a>b, the pallet The four corners and the middle part of 1 are respectively provided with anchor cable holes, the bottom of the third anchor cable 23 is fixed on the pallet 1 by the lock 3, and the bottoms of the two first anchor cables 21 are fixed on the pallet by the lock 3 1, the bottoms of the two second anchor cables 22 are fixed on the other side of the pallet 1 by the lock 3.

[0032] Further, five anchor cable pads 4 are included, and the anchor cable pads 4 are located between the lock 3 and the bottom surface of th...

Embodiment 2

[0034] Further, an anchor cable hole is opened on the surface of the tray 1, and also includes an anti-fall anchor cable 5, the bottom of the anti-fall anchor cable 5 is provided with a stopper 6, and the top of the anti-fall anchor cable 5 is lifted from the tray 1 Stretch out upwards in the anchor cable hole, anti-drop anchor rod 5 does not carry out the pretightening and only plays the effect of hanging large pallet 1 when large pallet 1 falls so that it does not fall and smash people.

[0035] Further, the diameter of the first anchor cable 21, the second anchor cable 22 and the third anchor cable 23 is 22mm, and the lengths are 8600mm, 7400mm and 9800mm respectively;

[0036] The length, width and height of tray 1 are 800mm, 900mm and 16mm respectively;

[0037] The length, width and height of the anchor cable cushion block 4 are 150mm, 150mm and 16mm respectively;

[0038] Anchor cable hole diameter is 25mm;

[0039] The distances from the centers of the anchor holes a...

Embodiment 3

[0041] Taking an above-ground tunnel fan chamber as an example, considering the safety of support, it is required to check the maximum support strength of the roadway in the chamber section during theoretical calculation. Then when the full width is checked, the possible fall height of the roof and the rock weight (per meter of roadway) are:

[0042] W=B×h×γ=7.5 / 8.5×4.3×25=806.25KN / 913.75KN;

[0043] In the formula, B is the width of the roadway, B=7.5 / 8.5m; h is the maximum possible caving height of the roof, combined with the actual roof of the 6-coal coal seam, the lithology of the roof of the electromechanical chamber section: 0-3.8m sandy mudstone; 3.8- 4.3m carbonaceous mudstone; 4.3-7.0m sandy mudstone; 7.0-7.1m coal; 7.1-9.6m sandy mudstone; the maximum possible caving height is 4.3m; γ is the rock bulk density, γ=25KN / m3.

[0044] In order to ensure the complete reliability of the support, the auxiliary support force of the roof bolt is not considered in the theoreti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com