Sheet Bundle Binding Device And Image Forming System Having The Same

A processing device and sheet technology, which can be used in thin material processing, stack receiving device, transportation and packaging, etc., and can solve the problems of limited number of sheets and reduced binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

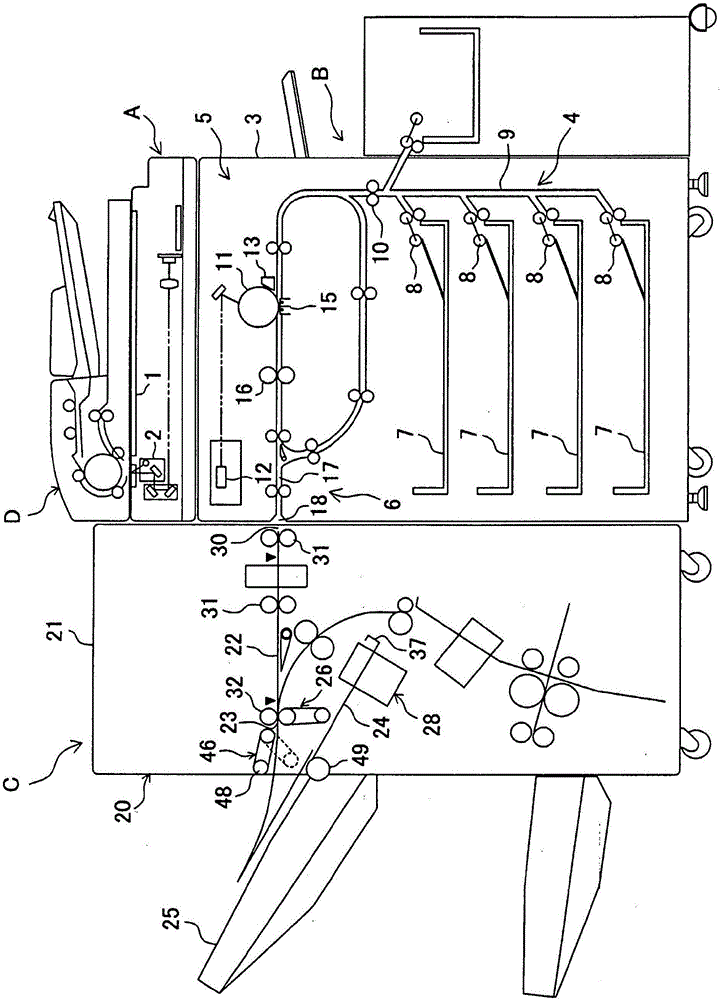

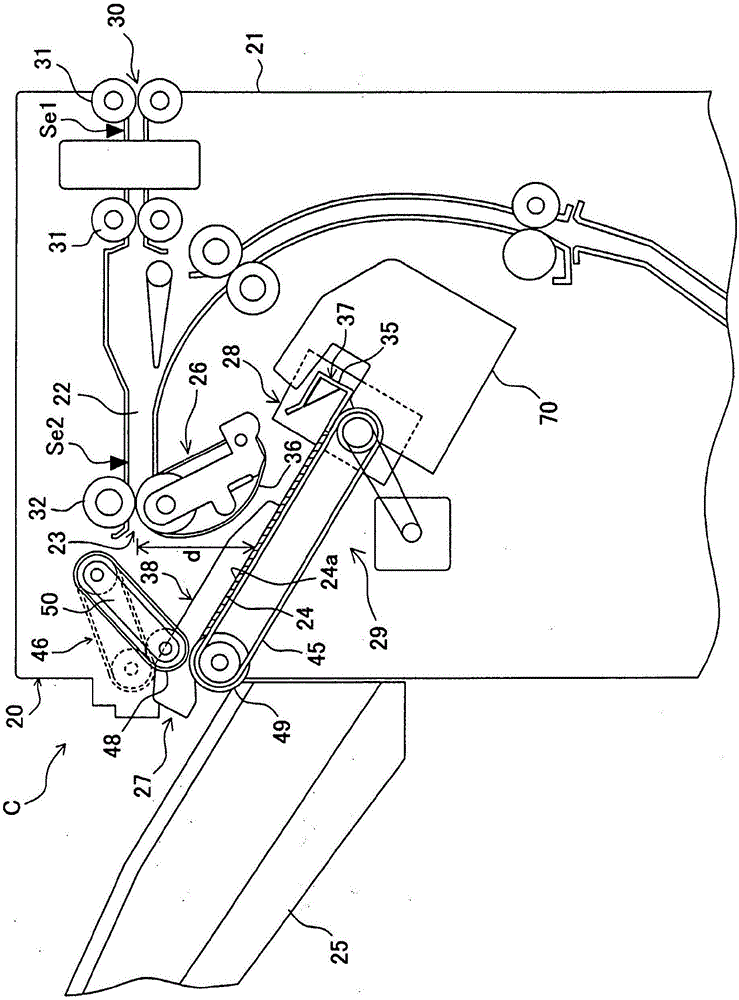

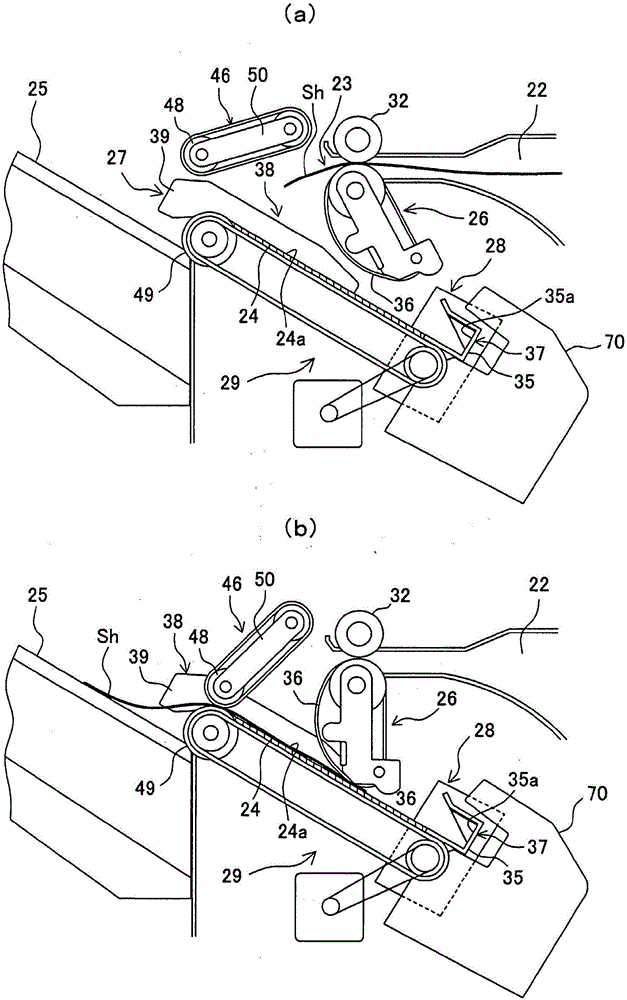

[0082] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the drawings, the same reference numerals are assigned to similar components throughout the specification.

[0083] In addition, in this specification, "offset conveyance of the sheet bundle" means that the sheet bundle formed by accumulating the sheets loaded onto the processing tray from the paper discharge port is moved in a direction perpendicular to (or intersecting) the sheet conveyance direction. Move in the direction (as far as possible to move to the side), and "offset" refers to the amount of movement. In addition, "alignment of sheet bundles" refers to aligning a plurality of sheets of different sizes loaded from the paper discharge port onto the processing tray according to a predetermined standard (for example, the direction perpendicular to the sheet conveyance direction as the processing tray, i.e. The center reference o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com