Composite negative electrode material, preparation method thereof, battery negative electrode and lithium ion battery

A negative electrode material and polymer technology, applied in the field of battery materials, can solve the problems of material performance impact, unstable large particles, and graphite layer peeling, and achieve the effects of uniform size, good cycle performance, and increased specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

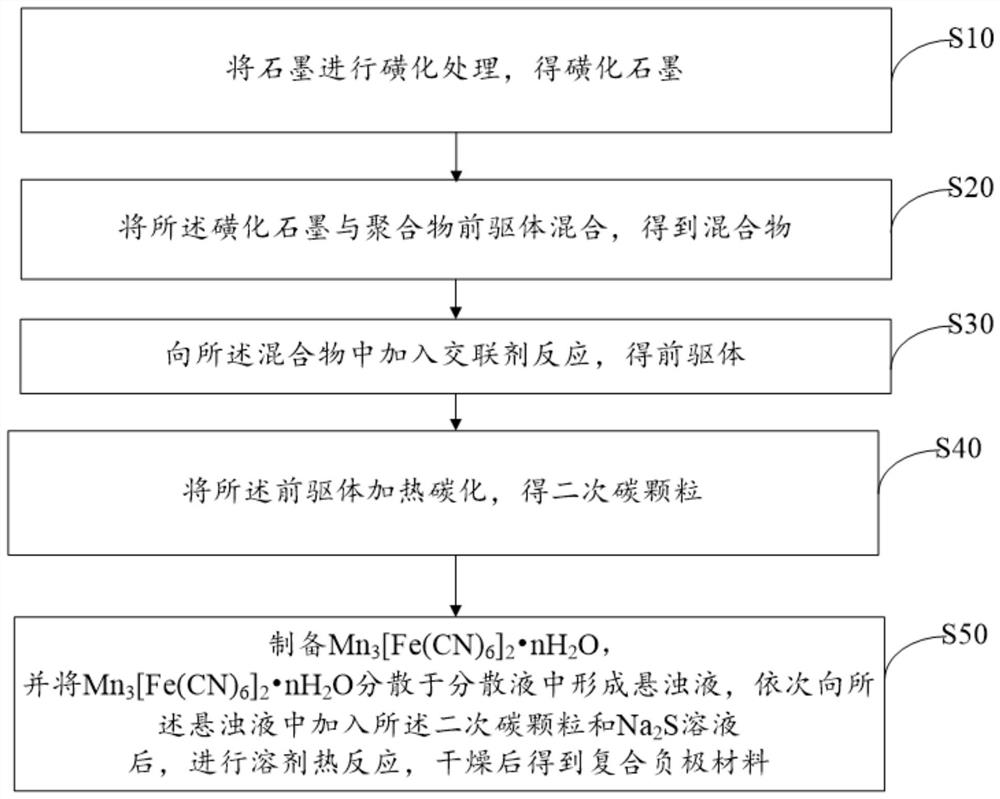

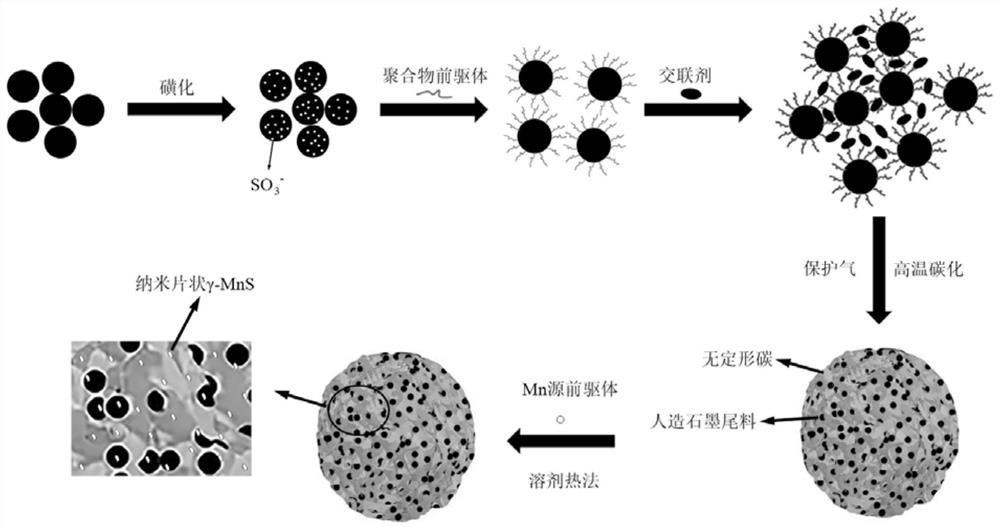

[0080] The present application further proposes a preparation method of the composite negative electrode material, figure 1 For a schematic flowchart of an embodiment of the method for preparing a composite negative electrode material proposed in this application, please refer to figure 1 , the preparation method of composite negative electrode material comprises the following steps:

[0081] S10, sulfonating the graphite to obtain sulfonated graphite.

[0082] In the embodiment of the present application, it is preferable to use graphite tailings for processing. Before preparing the graphite as the negative electrode material for the battery, the graphite needs to be classified to obtain the negative electrode material with the desired particle size range and the graphite tailings with a particle size of less than 2 μm. The embodiments of the present application aim to use graphite tailings with a particle size of less than 2 μm to prepare secondary carbon particles, so as t...

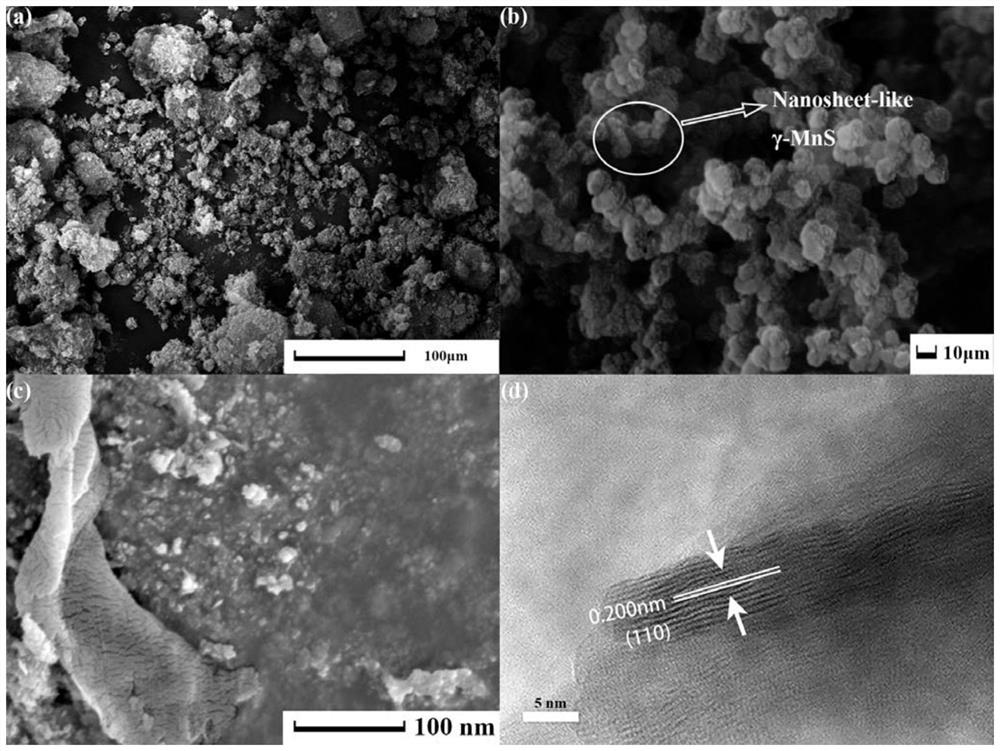

Embodiment 1

[0120] (1) Sulfonation of graphite tailings: 5.0 g of graphite tailings were added to a mixed solution of 5 mL of concentrated sulfuric acid and 100 mL of acetic anhydride, and stirred at 70° C. for 4 h to obtain crude sulfonated graphite tailings.

[0121] The crude sulfonated graphite tailings were repeatedly washed with deionized water until the pH of the cleaning solution was neutral, and then dried in a vacuum drying oven at 60 °C for 24 h.

[0122] (2) Disperse 0.5 g of citric acid in 30 mL of deionized water, stir with a magnetic stirrer for 30 min at 60° C. to obtain a solution; gradually add 0.5 g of the sulfonated graphite tailings prepared in step (1) to the solution, and then add 0.5 g of the sulfonated graphite tailings prepared in step (1). At 60 °C, stir with a magnetic stirrer for 2 h to obtain a mixed solution;

[0123] (3) Add 0.32 g of ethylene glycol (ethylene glycol:citric acid=2:1, mol / mol) to the mixed solution in step (2). Stir at 130 °C for 6 h to obt...

Embodiment 2

[0129] (1) Sulfonation of graphite tailings: Add 1.05 g of graphite tailings to a mixed solution of 5 mL of concentrated sulfuric acid and 100 mL of acetic anhydride, and stir at 70° C. for 4 h to obtain crude sulfonated graphite tailings.

[0130] The crude sulfonated graphite tailings were repeatedly washed with deionized water until the pH of the cleaning solution was neutral, and then dried in a vacuum drying oven at 60 °C for 24 h.

[0131] (2) Disperse 0.5 g of citric acid in 30 mL of deionized water, stir with a magnetic stirrer for 30 min at 60° C. to obtain a solution; gradually add 0.5 g of the sulfonated graphite tailings prepared in step (1) to the solution, and then add 0.5 g of the sulfonated graphite tailings prepared in step (1). At 60 °C, stir with a magnetic stirrer for 2 h to obtain a mixed solution;

[0132] (3) adding glycerol to the mixed solution in step (2) so that the molar ratio of glycerol and citric acid is 1:1, and stirring at 130° C. for 6 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com