Fully automatic electric needle-free environmental paper stapler

A fully automatic, paper-binding technology, applied in binding and other directions, can solve the problems of failing to achieve the use effect and work efficiency, difficult to popularize and apply needleless staplers, inconvenient to use on the table, and achieve the mechanical transmission process. Stable and reliable, small torque, large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

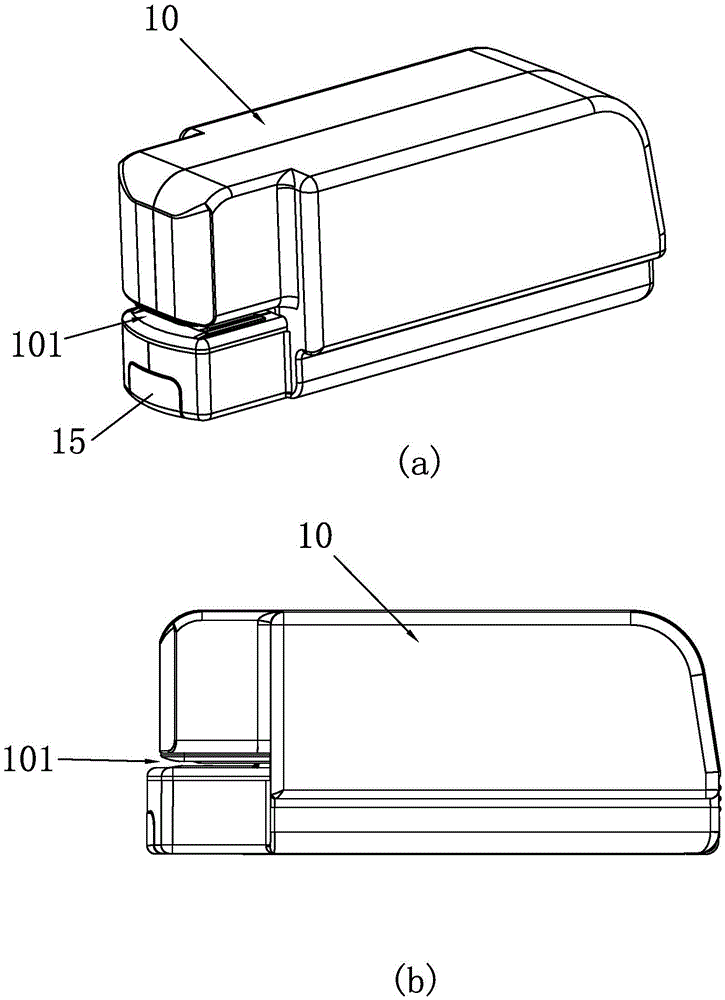

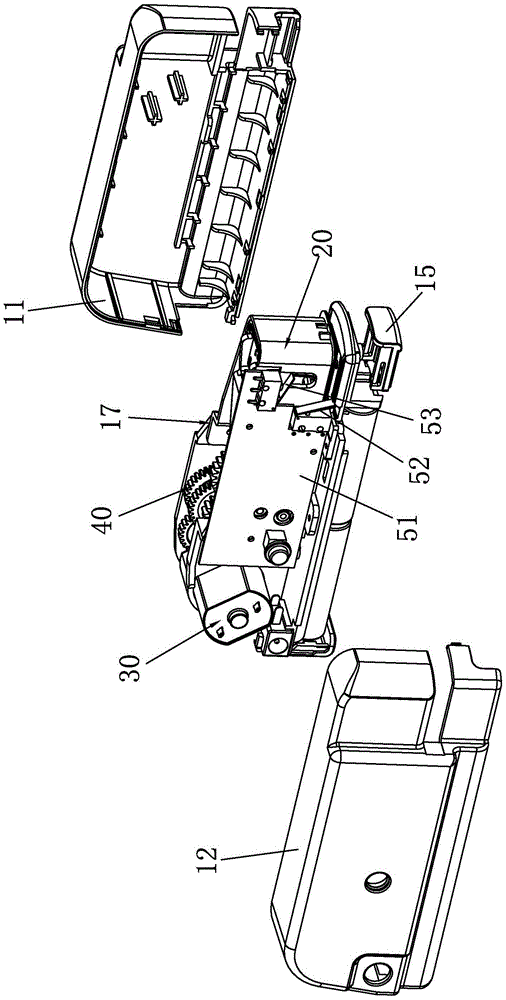

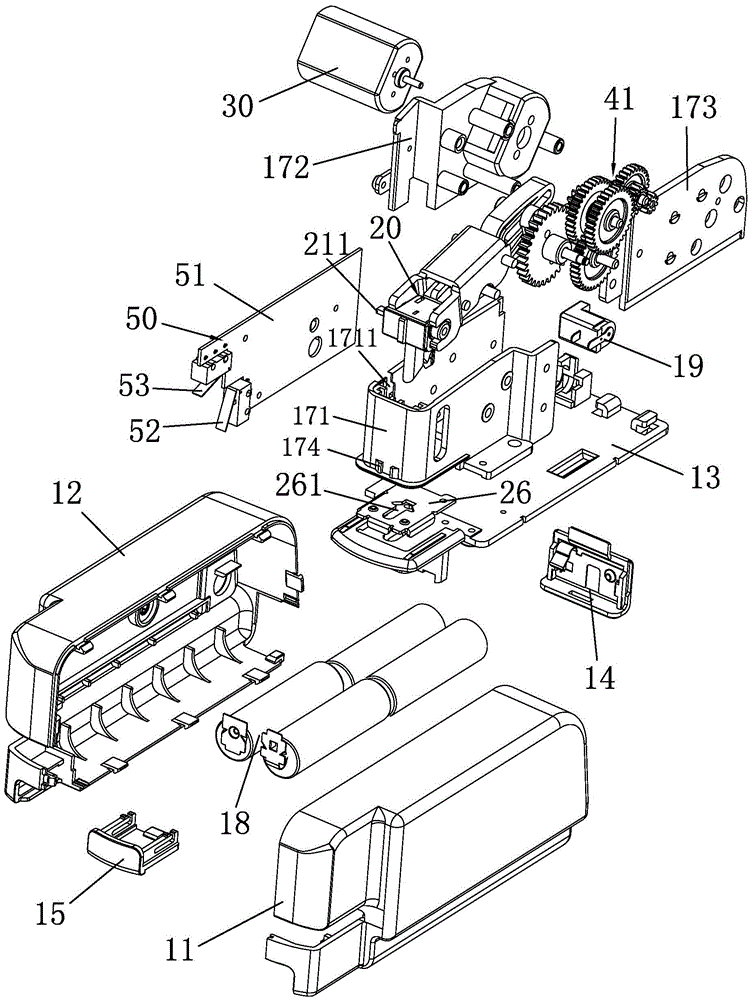

[0079] Please refer to Figure 1 to Figure 13 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes a housing 10 and a needleless stapler assembly 20 installed in the housing 10, the housing 10 is provided with a binding opening 101 (such as figure 1 and figure 2 As shown), the needleless paper stapling assembly 20 is set corresponding to the position of the binding port 101. For the needleless paper stapling assembly 20, a power supply, a motor 30, and a mechanical transmission between the motor 30 and the needleless paper stapling assembly 20 are provided. 40 pieces, an automatic control assembly 50 for controlling the opening and closing of the motor 30 and a bracket 17 for arranging the motor 30 and the mechanical transmission set 40, wherein the bracket 17 is fixed relative to the aforementioned housing 10 .

[0080] See Figure 2 to Figure 5 , Figure 10 to Figure 11 As shown, the mechanical transmission group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com