Positive electrode material, preparation method thereof and lithium ion battery

A technology of positive electrode materials and active materials, applied in the field of positive electrode materials and their preparation, can solve problems such as cladding layer and material surface delamination, adverse effects on battery electrochemical performance, limited increase in energy density, etc., to achieve improved surface stability performance, good chemical stability, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

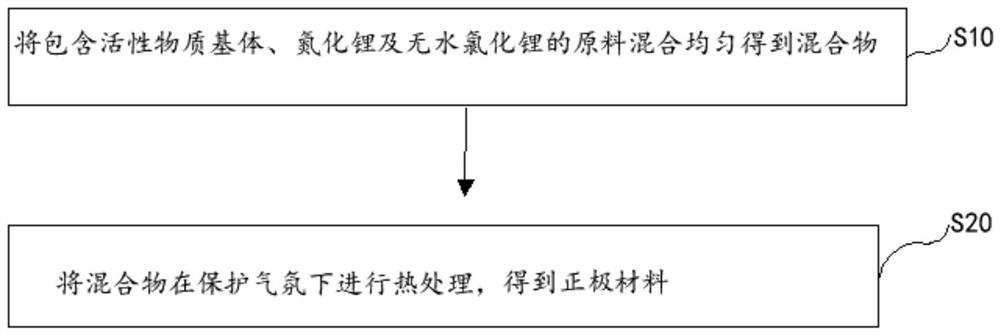

[0082] In the second aspect, the present application provides a method for preparing a cathode material, Figure 1 The flow diagram of the preparation method of the cathode material provided for the embodiment of the application is as follows: Figure 1 As shown, the preparation method comprises the following steps S10 to S20:

[0083] S10, mixing the active material matrix, lithium nitride and anhydrous lithium chloride evenly to obtain the mixture;

[0084] S20, heat treat the mixture in a protective atmosphere to obtain a positive electrode material.

[0085] In the above scheme, lithium nitride and anhydrous lithium chloride form Li on the surface of the active material matrix 3 N cladding, LiCl cladding and Li 9 N 2 Cl 3 At least two of the cladding, Li 3 N cladding, LiCl cladding and Li 9 N 2 Cl 3 The composite of coating layer can realize the effect of multiple coating. However, in the prior art, multi-step processing is required to realize the doping and coating process. Fir...

Embodiment 1

[0121] (1) Dissolve the Ni source, Co source and Mn source according to the molar ratio Ni ∶ Co: Mn = 0.83 ∶ 0.11 ∶ 0.06 to prepare an aqueous solution of 2.0mol / l, prepare 8mol / L sodium hydroxide solution and 2mol / L ammonia solution, and carry out coprecipitation reaction to synthesize the precursor.

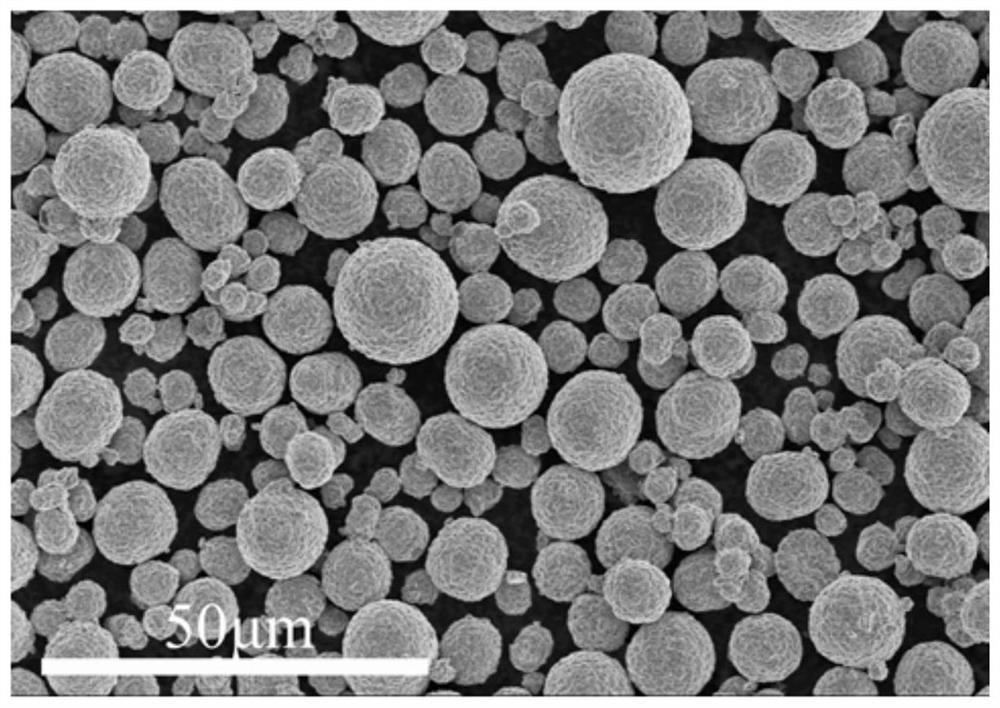

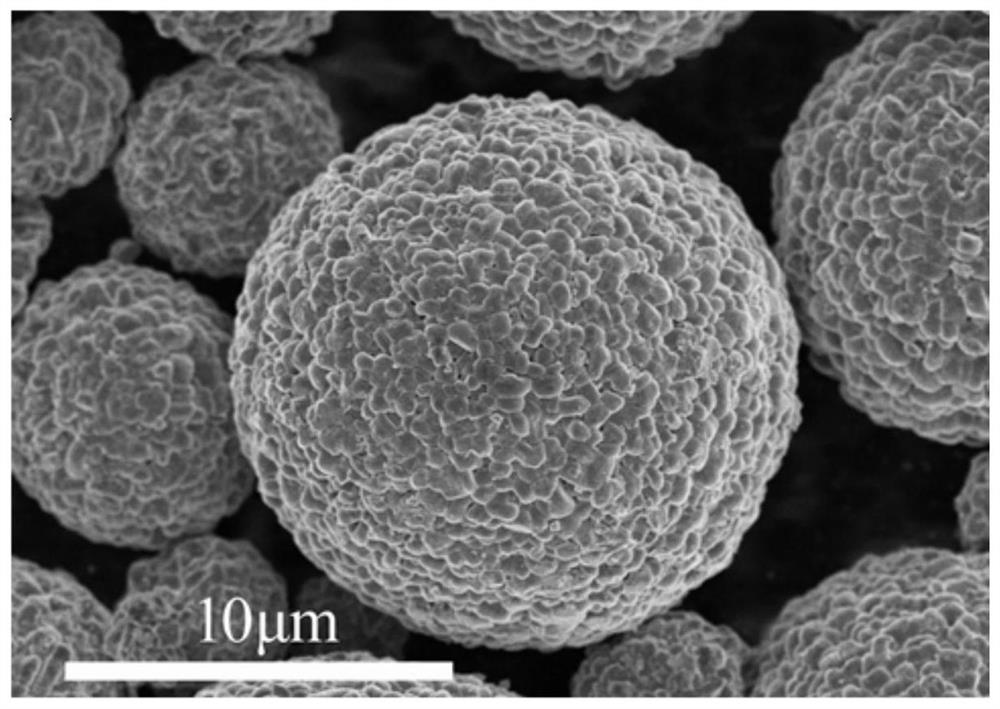

[0122] (2) The obtained precursor is fully mixed with excess LiOH to obtain the first mixture. The first mixture is placed in the atmosphere of pure oxygen, the furnace pressure is controlled at 10Pa, the temperature is raised to 800 ℃ at the heating rate of 1.5 ℃ / min, and the sintering treatment is continued for 9 hours. Lini is obtained after natural cooling 0.83 Co 0.11 Mn 0.06 O 2 Active material matrix. Figure 2A 、 Figure 2B A scanning electron microscope photograph of the cathode material of embodiment 1 of the present application, such as Figure 2A 、 Figure 2B As shown in the figure, it can be seen that the outline of the spherical primary particles is clear, and the s...

Embodiment 2

[0128] Different from embodiment 1, (3) use a high mixer to mix the above lini 0.83 Co 0.11 Mn 0.06 O 2 Active material matrix and lithium nitride (Li 3 N) Powder and anhydrous LiCl powder (Li 3 The molar ratio of n to LiCl is 2:3) and the second mixture is obtained by uniformly mixing for 1H according to the mass ratio of 100:1. The second mixture is put into a crucible for heat treatment, sintered into nitrogen atmosphere, heated to 700 ℃ at the rate of 3 ℃ / min, heat treated for 5 hours, and cooled with the furnace to obtain the cathode material.

[0129] The cathode material of embodiment 2 includes an active material matrix lini 0.83 Co 0.11 Mn 0.06 O 2 And a coating layer formed on the surface of the active material substrate, which includes Li 3 N and LiCl, the mass ratio of active material matrix to coating layer is 100:1, and the thickness of coating layer is 2nm. The cathode material includes secondary particles composed of a plurality of primary particles. The average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com