A kind of low-expansion silicon-carbon composite negative electrode material and preparation method thereof

A negative electrode material, silicon carbon composite technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor cycle and rate performance of silicon carbon materials, and achieve improved cycle and storage performance, high ionic conductivity, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

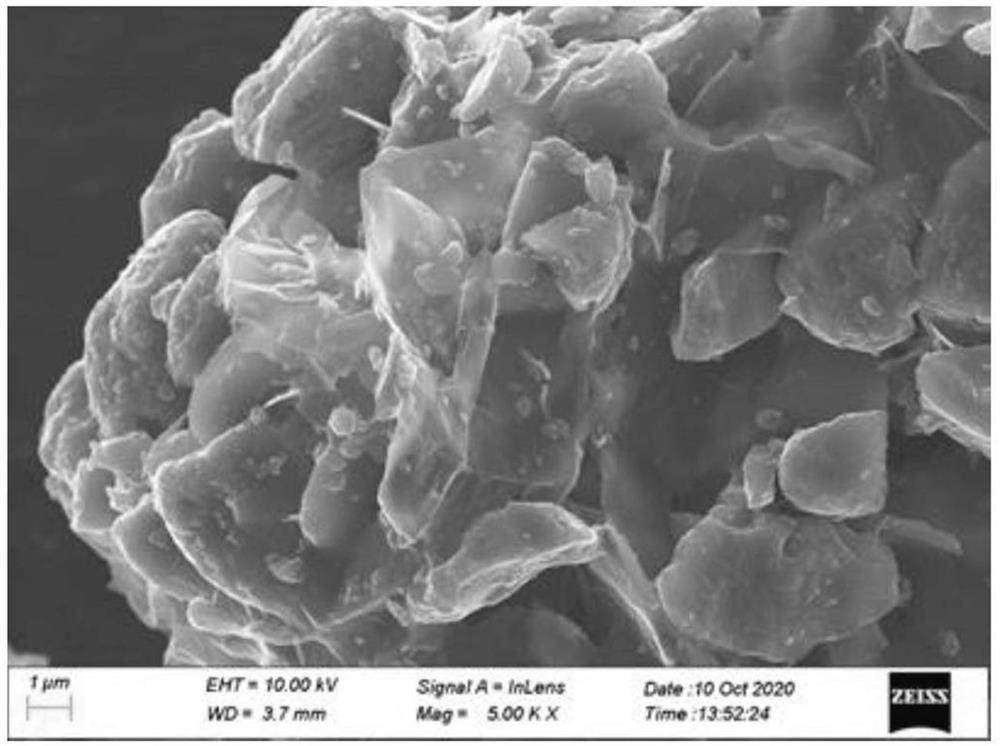

Image

Examples

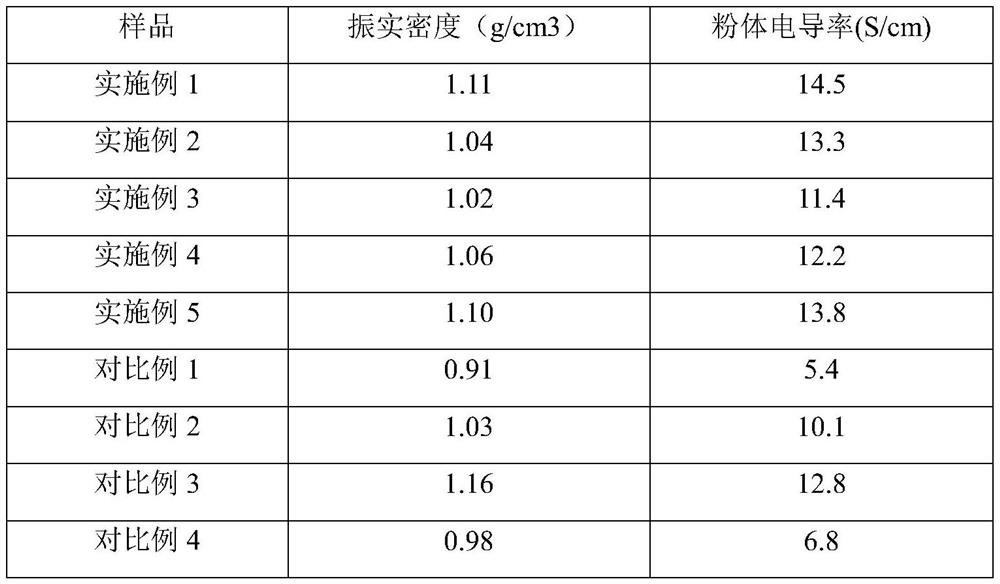

Embodiment 1

[0032] S1, mix 3g lithium lanthanum zirconate, 3g aminated graphene TEPA, 3g γ-aminopropyltrimethoxysilane and 500g N-methylpyrrolidone to obtain a coating liquid;

[0033] S2, adding 20 g of silicon monoxide into the coating solution, and performing a hydrothermal reaction at a temperature of 150° C. and a pressure of 3 MPa for 6 hours to prepare a composite material B coated with a solid electrolyte on the surface;

[0034] S3. Mix 20 g of polyamic acid and N-methylpyrrolidone to prepare a 1% polyamic acid solution, then add 3 g of single-walled carbon nanotubes and 100 g of composite material B, and prepare a spinning solution with a concentration of 6.1 wt%;

[0035] S4. The spinning solution is sprayed onto the light plate by electrospinning, then pulverized and heated under nitrogen atmosphere to convert the polyamic acid into polyimide. The imide nanofiber membrane silicon-carbon composite material is a low-expansion silicon-carbon composite negative electrode material....

Embodiment 2

[0037] S1, mix 1g lithium lanthanum zirconate, 1g aminated graphene TEPA, 5g γ-aminopropyltriethoxysilane and 100g carbon tetrachloride to obtain a coating solution;

[0038] S2, adding 30 g of silicon monoxide into the coating liquid, and performing a hydrothermal reaction at a temperature of 150° C. and a pressure of 3 MPa for 6 hours to prepare a composite material B coated with a solid electrolyte on the surface;

[0039] S3. Mix 10 g of polyamic acid and N-methylpyrrolidone to prepare a 0.5% polyamic acid solution, then add 5 g of single-walled carbon nanotubes and 100 g of composite material B, and prepare a spinning solution with a concentration of 5.75 wt%;

[0040] S4. The spinning solution is sprayed onto the light plate by electrospinning, then pulverized and heated under nitrogen atmosphere to convert the polyamic acid into polyimide. The imide nanofiber membrane silicon-carbon composite material is a low-expansion silicon-carbon composite negative electrode materi...

Embodiment 3

[0042] S1, mix 5g lithium lanthanum zirconate, 5g aminated graphene TEPA, 1g γ-aminopropylmethyldiethoxysilane and 500g cyclohexane to obtain a coating solution;

[0043] S2, adding 50 g of silicon monoxide into the coating solution, and performing a hydrothermal reaction at a temperature of 150° C. and a pressure of 3 MPa for 6 hours to prepare a composite material B coated with a solid electrolyte on the surface;

[0044] S3, mix 30g of polyamic acid and N-methylpyrrolidone to prepare a 2% polyamic acid solution, then add 5g of single-wall carbon nanotubes, and 100g of composite material B, and prepare a spinning solution with a concentration of 9wt%;

[0045] S4. The spinning solution is sprayed onto a light plate by electrospinning, then pulverized and heated under a nitrogen atmosphere to convert the polyamic acid into polyimide. The imide nanofiber membrane silicon-carbon composite material is a low-expansion silicon-carbon composite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com