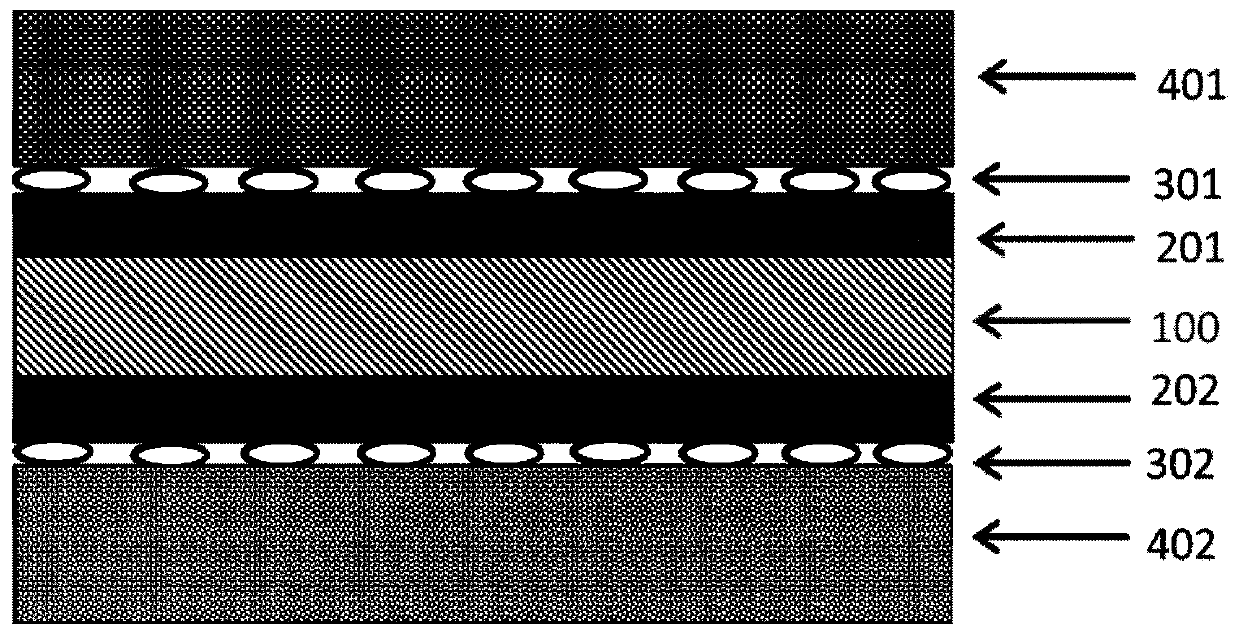

Battery-used separator and preparation method thereof

A diaphragm and battery technology, applied in the field of battery diaphragm and its preparation, can solve the problems of reducing the cycle life of the battery and the diaphragm is prone to plugging, and achieve the effects of reducing the risk of plugging, not endangering human health, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

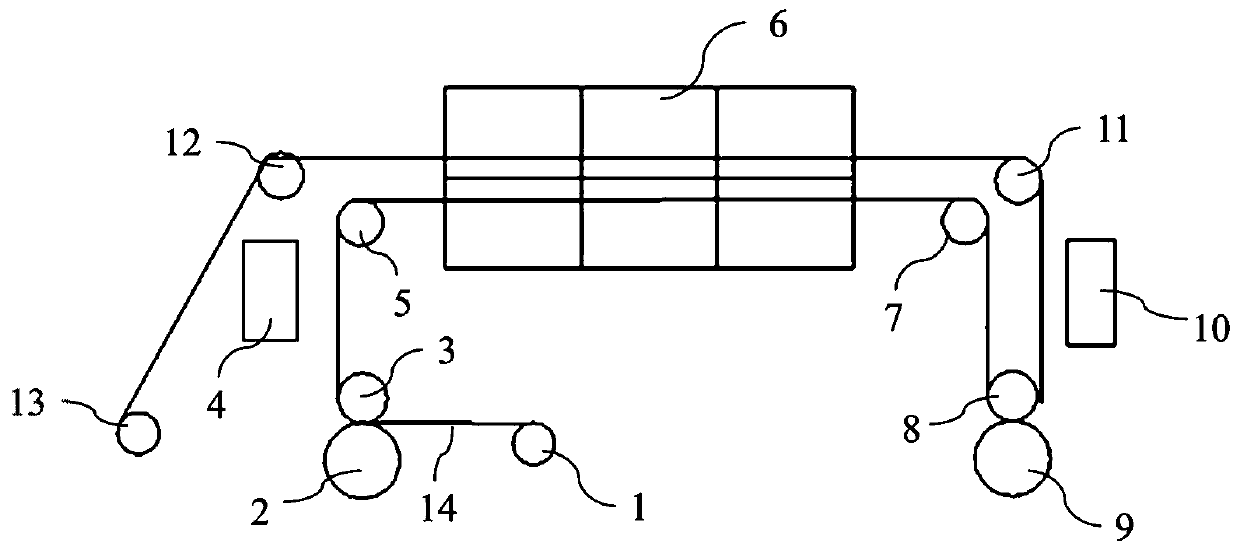

[0082] A method for preparing a battery diaphragm includes the following steps:

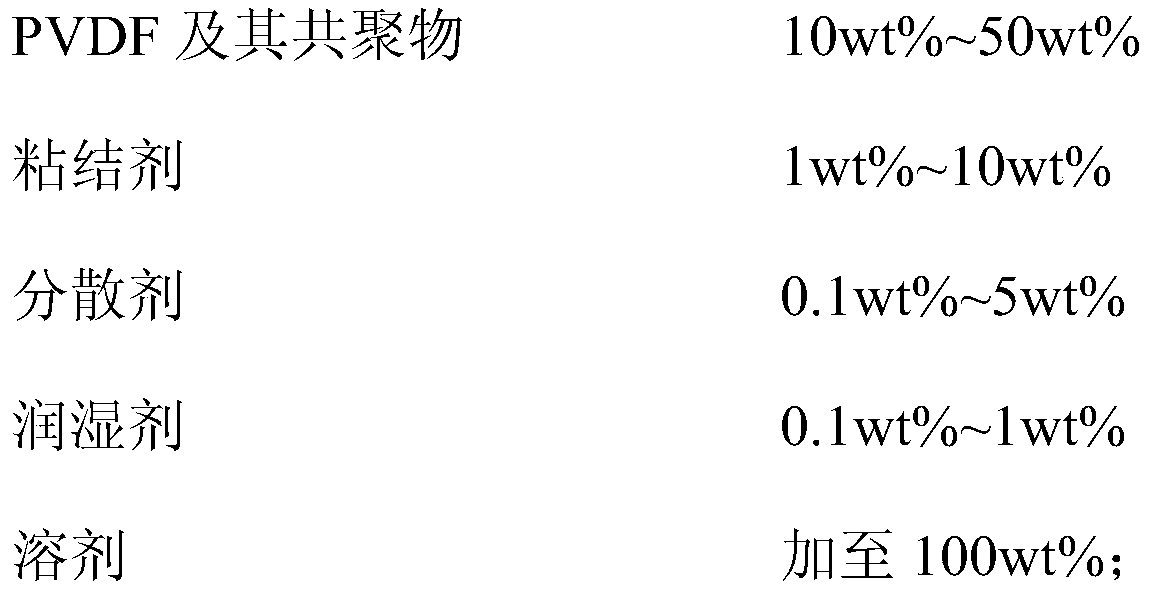

[0083] (1) Mix 35wt% alumina, 2wt% triethyl phosphate and 57.4wt% deionized water in proportion, stir for 1500r / min and mix for 2h, then add 5wt% polymethyl methacrylate, stir for 1500r / min and mix for 2h , Finally add 0.6wt% sodium dodecylbenzene sulfonate, stir 1500r / min and mix for 2h to prepare ceramic slurry, mix 25wt% polyvinylidene fluoride, 2wt% triethyl phosphate and 67.4wt% deionized water Proportional mixing, stirring 1500r / min for 2h, then adding 5wt% polymethyl methacrylate, stirring for 3h and mixing uniformly, and finally adding 0.6wt% sodium dodecylbenzene sulfonate, stirring for 1500r / min and mixing for 2h to prepare polymer Slurry

[0084] (2) After coating ceramic slurry on both sides of the PP film with anilox rollers, air spray the polymer slurry directly on both sides of the ceramic diaphragm. The coating area of the polymer slurry accounts for the total area of the base fil...

Embodiment 2

[0087] A method for preparing a battery diaphragm includes the following steps:

[0088] (1) Mix 50wt% boehmite, 5% polyethylene glycol and 41.9% deionized water in proportion, stir at 2000r / min for 1h, then add 3wt% polybutyl methacrylate, stir at 2000r / min for 1h, Finally, add 0.1wt% sodium lauryl sulfate, stir at 2000r / min and mix for 1h to prepare ceramic slurry. Mix 10wt% polyvinylidene fluoride-trifluoroethylene, 0.1wt% polyethylene glycol and 78.8wt% deionized water Mix in proportion, stir 500r / min for 5h, then add 10wt% polybutyl methacrylate, stir for 5h and mix uniformly, finally add 1wt% sodium lauryl sulfate, stir for 500r / min and mix for 5h to prepare polymer slurry ;

[0089] (2) After coating ceramic slurry on both sides of the PP film with anilox rollers, air spray the polymer slurry directly on both sides of the ceramic diaphragm. The coating area of the polymer slurry accounts for the total area of the base film. The percentage is 10%. After drying at 60°C, ...

Embodiment 3

[0091] A method for preparing a battery diaphragm includes the following steps:

[0092] (1) Mix 20wt% zinc oxide, 0.1wt% ammonium polyacrylate and 68.9wt% deionized water in proportion, stir 500r / min for 5h, then add 10wt% styrene butadiene latex, stir 500r / min for 5h, and finally add 1wt% sodium butyl naphthalene sulfonate, stir 500r / min for 5h to prepare ceramic slurry, mix 50wt% polyvinylidene fluoride-hexafluoroethylene, 5wt% ammonium polyacrylate and 43.9wt% deionized water in proportion, Stir at 2000r / min for 1h, then add 1wt% styrene-butadiene latex, stir for 1h and mix uniformly, finally add 0.1wt% sodium butyl naphthalene sulfonate, stir at 2000r / min for 1h to prepare polymer slurry;

[0093] (2) After coating ceramic slurry on both sides of the PE film with anilox rollers, air spray the polymer slurry directly on both sides of the ceramic diaphragm. The coating area of the polymer slurry accounts for the total area of the base film. The percentage is 50%, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com