Surface coating for improving security performance of power lithium ion battery, surface coating application and power lithium ion battery

A lithium-ion battery, safety performance technology, applied in surface coating applications and power lithium-ion battery, power lithium-ion battery, surface coating field, can solve the problem of reducing battery power performance and energy density, aggravating battery polarization phenomenon, increasing battery, etc. problems, to achieve the effect of improving cycle life, avoiding direct contact, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

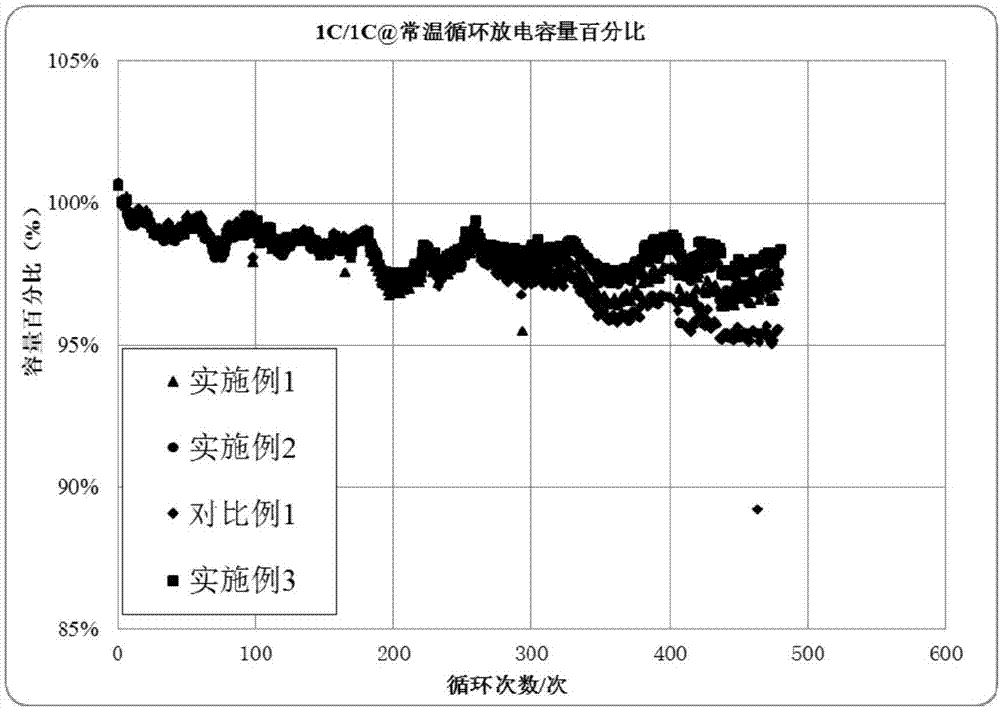

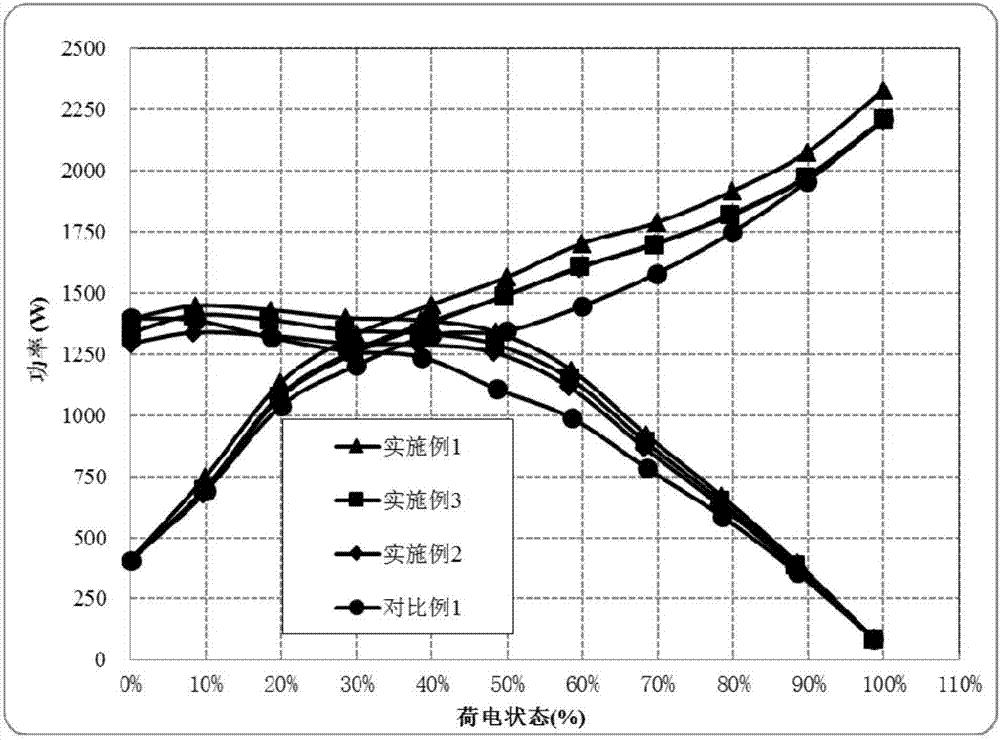

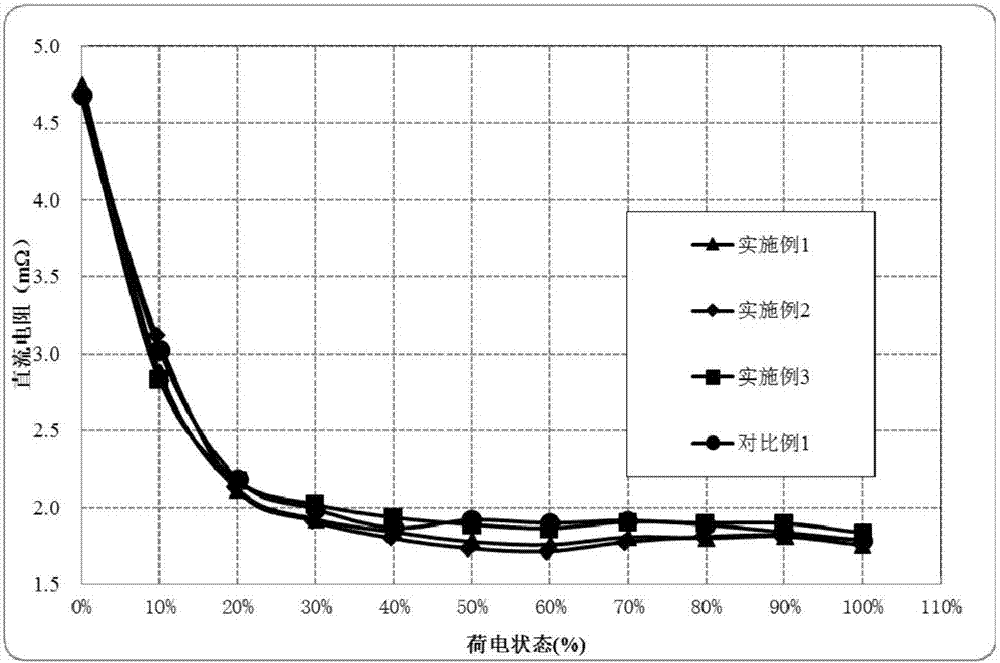

Embodiment 1

[0027] (1) Preparation of surface coating slurry: the α-Al of 30% mass ratio 2 o 3 , 4.0% by mass ratio of polyvinylidene fluoride (PVDF) were added to 66% by mass ratio of N-methylpyrrolidone (NMP), stirred at a speed of 1500-2000r / min for 2-6 hours and evenly mixed to form a surface coating slurry.

[0028] (2) Preparation of positive electrode slurry: LiNi with 98.25% mass ratio 1 / 3Mn 1 / 3Co 1 / 3O 2 The positive electrode active material, the carbon nanotube (CNT) conductive agent of 0.6% by mass ratio, and the polyvinylidene fluoride (PVDF) of 1.15% by mass ratio are added in N-methylpyrrolidone (NMP) respectively, under the rotating speed 2000r / min Stir to mix evenly to form positive electrode slurry.

[0029] (3) Preparation of negative electrode slurry: carboxymethyl cellulose (CMC) and 1.8% mass ratio of artificial graphite of 76.56% mass ratio, natural graphite of 19.14% mass ratio, conductive carbon black of 1% mass ratio, 1.5% mass ratio The mass ratio of st...

Embodiment 2

[0045] (1) Preparation of surface coating slurry: the AlOOH of 30% mass ratio, the polyvinylidene fluoride (PVDF) of 5.0% mass ratio are respectively added in the N-methylpyrrolidone (NMP) of 60% mass ratio, at the rotating speed Stir at 1500-2000r / min for 2-6 hours to evenly mix to form surface coating slurry.

[0046] (2) Preparation of positive electrode slurry: LiNi with 98.25% mass ratio 0.5 mn 0.3 co 0.2 o 2 The positive electrode active material, the carbon nanotube (CNT) conductive agent of 0.6% by mass ratio, and the polyvinylidene fluoride (PVDF) of 1.15% by mass ratio are added in N-methylpyrrolidone (NMP) respectively, under the rotating speed 2000r / min Stir to mix evenly to form positive electrode slurry.

[0047] (3) Preparation of negative electrode slurry: carboxymethyl cellulose (CMC) and 1.8% mass ratio of artificial graphite of 76.56% mass ratio, natural graphite of 19.14% mass ratio, conductive carbon black of 1% mass ratio, 1.5% mass ratio The mass ra...

Embodiment 3

[0055] (1) Preparation of surface coating slurry: the α-Al of 30% mass ratio 2 o 3 , 5.0% by mass ratio of polyvinylidene fluoride (PVDF) were added to 65% by mass ratio of N-methylpyrrolidone (NMP), stirred at a speed of 1500-2000r / min for 2-6 hours and evenly mixed to form a surface coating slurry.

[0056] (2) Preparation of positive electrode slurry: LiNi with 98.25% mass ratio 0.5 mn 0.3 co 0.2 o 2 The positive electrode active material, the carbon nanotube (CNT) conductive agent of 0.6% by mass ratio, and the polyvinylidene fluoride (PVDF) of 1.15% by mass ratio are added in N-methylpyrrolidone (NMP) respectively, under the rotating speed 2000r / min Stir to mix evenly to form positive electrode slurry.

[0057] (3) Preparation of negative electrode slurry: carboxymethyl cellulose (CMC) and 1.8% mass ratio of artificial graphite of 76.56% mass ratio, natural graphite of 19.14% mass ratio, conductive carbon black of 1% mass ratio, 1.5% mass ratio The mass ratio of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com