Polymer for lithium ion battery, preparation method of polymer, lithium ion battery gel electrolyte and preparation method thereof

A technology of lithium ion battery and gel electrolyte, applied in the field of lithium ion battery and its preparation, can solve the problems of inability to meet ultra-thin electronic devices, low energy density, low safety factor, etc., and achieves improved safety factor, excellent chemical performance, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The electrolyte solution is mixed with the raw materials and additives for preparing polymers for lithium-ion batteries, and the mixed solution is heated at 70°C for 2 hours, and the raw materials for preparing polymers for lithium-ion batteries are exchanged under the action of additives. to form polymers for lithium-ion batteries. Lithium-ion batteries use polymers to firmly adsorb the electrolyte solution to form a lithium-ion battery gel electrolyte.

[0050] Wherein, the electrolyte solution is an organic solvent in which lithium salt is dissolved, and the lithium salt concentration is 0.5 mol / L. The lithium salt is lithium hexafluorophosphate, the organic solvent is vinylene carbonate and diethyl carbonate, and the weight ratio of vinylene carbonate and diethyl carbonate is 1:1.

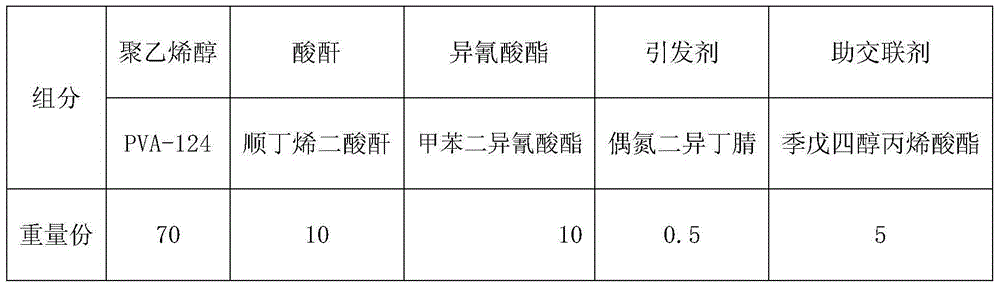

[0051] The proportioning ratio of the raw materials and auxiliary agents used to prepare the polymer for lithium ion batteries is shown in Table 1, and the weight of the prepared polyme...

Embodiment 2

[0055] The electrolyte solution is mixed with the raw materials and additives for preparing polymers for lithium-ion batteries, and the mixed solution is heated at 70°C for 2 hours, and the raw materials for preparing polymers for lithium-ion batteries are exchanged under the action of additives. to form polymers for lithium-ion batteries. Lithium-ion batteries use polymers to firmly adsorb the electrolyte solution to form a lithium-ion battery gel electrolyte.

[0056] Wherein, the electrolyte solution is an organic solvent in which lithium salt is dissolved, and the lithium salt concentration is 1.5 mol / L. The lithium salt is lithium hexafluorophosphate, the organic solvent is vinylene carbonate and diethyl carbonate, and the weight ratio of vinylene carbonate and diethyl carbonate is 1:1.

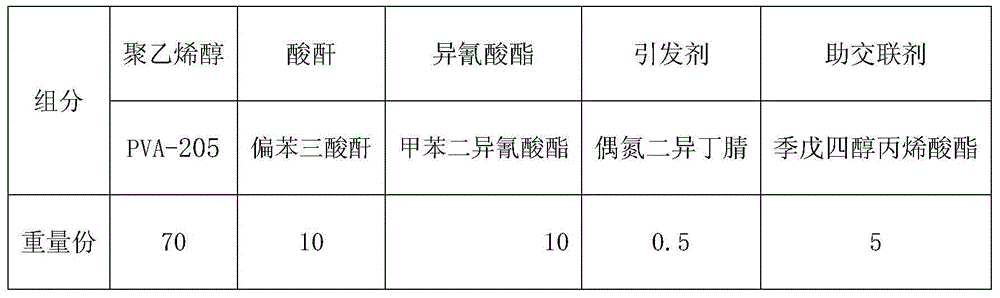

[0057] The proportioning ratio of the raw materials and auxiliary agents used to prepare the polymer for lithium ion batteries is shown in Table 2, and the weight of the prepared polyme...

Embodiment 3

[0061] The electrolyte solution is mixed with the raw materials and additives for preparing polymers for lithium-ion batteries, and the mixed solution is heated at 70°C for 2 hours, and the raw materials for preparing polymers for lithium-ion batteries are exchanged under the action of additives. link to form polymers. Lithium-ion batteries use polymers to firmly adsorb the electrolyte solution to form a lithium-ion battery gel electrolyte.

[0062] Wherein, the electrolyte solution is an organic solvent in which lithium salt is dissolved, and the lithium salt concentration is 1.0 mol / L. The lithium salt is lithium hexafluorophosphate, the organic solvent is vinylene carbonate and diethyl carbonate, and the weight ratio of vinylene carbonate and diethyl carbonate is 1:1.

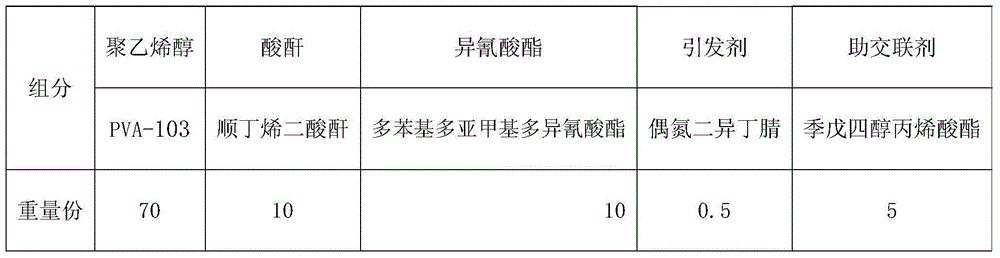

[0063] The proportioning ratio of raw materials and auxiliary agents used to prepare the polymer for lithium ion batteries is shown in Table 3, and the weight of the prepared polymer for lithium ion batteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com