Lithium ion battery positive electrode plate and manufacturing method thereof

A lithium-ion battery and manufacturing method technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problem that the contact area between the activated carbon layer and the aluminum foil current collector is small, the current collector occupies a large space, and the electrode is conductive. In order to reduce the volume ratio of the current collector, improve the conductivity, and increase the coating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

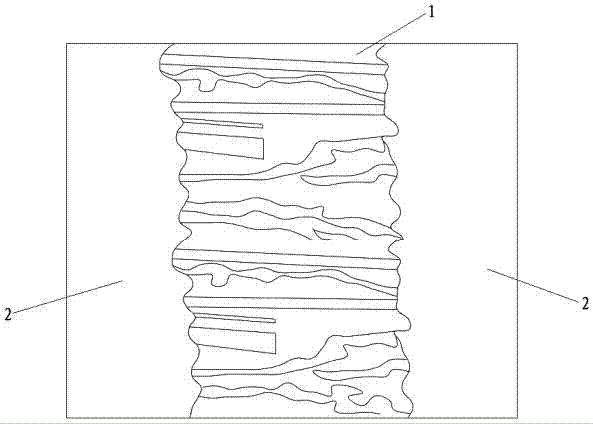

[0026] This embodiment provides a lithium-ion battery positive sheet, including a porous current collector aluminum foil (1) and a positive electrode material layer (2), the porous current collector aluminum foil (1) is distributed with through holes and non-through holes, the porous Both sides of the current collector aluminum foil (1) are coated with a positive electrode material layer (2).

[0027] Preferably, the thickness of the porous current collector aluminum foil (1) is 10-50 μm, the porosity of the porous current collector aluminum foil (1) is 5% to 40%, and the ratio of through holes on the porous current collector aluminum foil (1) is 2 %~35%.

[0028] Preferably, the equivalent diameter of the through hole and the non-through hole is 0.5-5 μm.

Embodiment 2

[0030] A positive electrode sheet of a lithium ion battery of the present embodiment and a manufacturing method thereof, comprising the following steps:

[0031] ①Take an aluminum foil with a thickness of 20 μm, and perform DC etching on the aluminum foil with the parameters of energizing current 0.7A and energizing time 0.5s;

[0032] ②The aluminum foil after DC etching is chemically etched by concentrated sulfuric acid. The equivalent diameter of the surface pores of the etched aluminum foil is 2.7 μm, the porosity is 31%, and the through hole ratio is 22%;

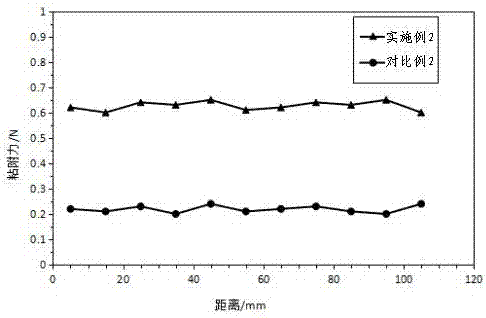

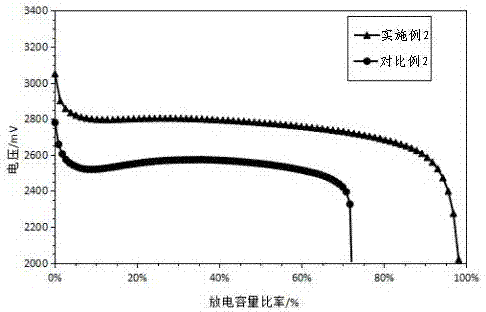

[0033] ③The positive lithium iron phosphate slurry is coated on both sides of the porous current collector aluminum foil (1) of this example through a coating machine, and the positive electrode sheet is obtained after drying, and then passed through a rolling machine, a slitting machine, and a winding A 5Ah aluminum shell square battery cell with a length of 110mm, a width of 60mm, and a thickness of 6mm was prepared b...

Embodiment 3

[0037] A positive electrode sheet of a lithium ion battery of the present embodiment and a manufacturing method thereof, comprising the following steps:

[0038] ① Take a current collector aluminum foil with a thickness of 20 μm, and perform DC etching on the current collector aluminum foil with the parameters of energizing current 1A and energizing time 0.5s;

[0039] ②The aluminum foil after DC etching is chemically etched by concentrated sulfuric acid. The equivalent diameter of the surface pores of the etched aluminum foil is 3 μm, the porosity is 30%, and the through hole ratio is 23%;

[0040] ③ Coat the positive electrode lithium iron phosphate slurry on both sides of the porous current collector aluminum foil (1) prepared in this example through a coating machine, and obtain the positive electrode sheet after drying, and then pass through a rolling machine, a slitting machine, The winding machine prepares the cell, the cell length is 110mm, the width is 60mm, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com