Coated diaphragm for ternary lithium ion battery, and preparation method thereof

A lithium-ion battery and separator technology, applied in the field of preparation of lithium-ion battery separators, can solve the problems of insufficient battery safety performance and cycle performance, limited electrolyte inhibition effect, easy to generate heat accumulation, etc., to promote large-scale application, electronic Outstanding conductivity and the effect of suppressing structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

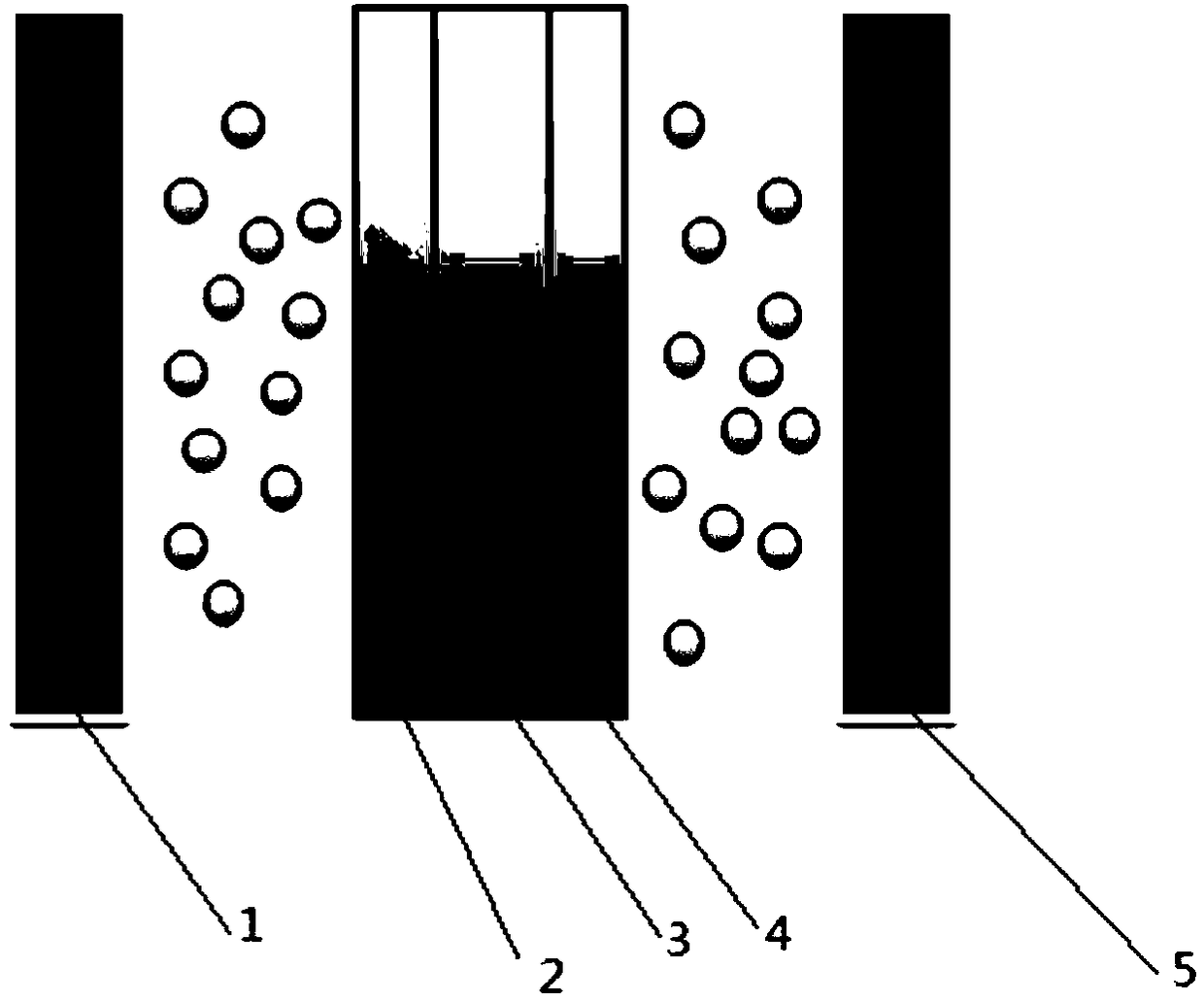

[0027] A kind of coating diaphragm of ternary lithium ion battery, comprises PE diaphragm substrate 3, ceramics / graphene composite coating 4, PVDF coating 2, and ceramics / graphene composite coating 4, PVDF coating 2 are respectively coated on On both sides of the diaphragm substrate 3, the ceramic / graphene composite coating 4 corresponds to the positive electrode 5 of the battery, the PVDF coating 2 corresponds to the negative electrode 1 of the battery, the PE diaphragm substrate 3 is 20 μm thick, and the ceramic / graphene The thickness of composite coating 4 and PVDF coating 2 is 5 μm.

[0028] Add nano-α-alumina powder, graphene oxide, gelatin, and polyvinylpyrrolidone with a mass ratio of 70:15:10:5 into a certain amount of deionized water for stirring and dispersing to obtain a mixed slurry with a solid content of 67%. Then the slurry was coated on one side of the PE diaphragm base material, dried and rolled, and left to stand for 120 minutes. Then take a little oily PVDF...

Embodiment 2

[0030] A coating diaphragm for a ternary lithium ion battery, comprising a PP diaphragm substrate 3, a ceramic / graphene composite coating 4, a PVDF coating 2, and the ceramic / graphene composite coating 4 and the PVDF coating 2 are respectively coated on On both sides of the diaphragm substrate 3, the ceramic / graphene composite coating 4 corresponds to the positive electrode 5 of the battery, the PVDF coating 2 corresponds to the negative electrode 1 of the battery, the thickness of the PP diaphragm substrate 3 is 4 μm, and the ceramic / graphene The thickness of composite coating 4 and PVDF coating 2 is 0.5 μm.

[0031] Add silicon oxide powder, reduced graphite oxide, LA133, and polyethylene glycol with a mass ratio of 65:20:8:7 to a certain amount of deionized water and n-propanol for stirring and dispersion to obtain a mixed slurry with a solid content of 59%. material, and then apply the slurry on one side of the PP separator substrate, dry, roll and let stand for 240 minute...

Embodiment 3

[0033] A coated diaphragm for a ternary lithium-ion battery, comprising a PE / PP composite diaphragm substrate 3, a ceramic / graphene composite coating 4, a PVDF coating 2, a ceramic / graphene composite coating 4, and a PVDF coating 2 respectively Coated on both sides of the separator substrate 3, the ceramic / graphene composite coating 4 corresponds to the positive electrode 5 of the battery, the PVDF coating 2 corresponds to the negative electrode 1 of the battery, and the PE / PP composite separator substrate 3 is 30 μm thick, The thickness of the ceramic / graphene composite coating 4 and the PVDF coating 2 is 10 μm.

[0034]Calcium oxide powder with a mass ratio of 72:11:9:8, nitrogen-doped functional graphene, sodium alginate, and polyethylene glycol were added to a certain amount of deionized water for stirring and dispersion, and a solid content of 61% was obtained. Mix the slurry, and then apply the slurry on one side of the PE / PP composite diaphragm substrate, dry, roll and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com