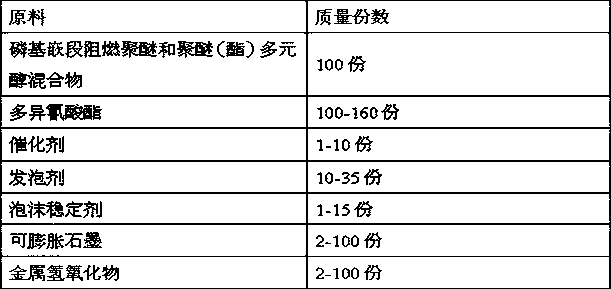

Phosphorus-based flame-retardant block polyether, preparation method thereof and application of phosphorus-based flame-retardant block polyether to rigid polyurethane foam

A technology of rigid polyurethane and flame-retardant polyether, which is applied in the field of flame-retardant polyurethane foam materials, can solve the problems of rigid polyurethane foam, poor dimensional stability, and low flame-retardant efficiency, and achieve excellent flame-retardant and mechanical properties, Good dimensional stability and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

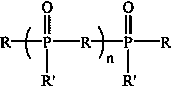

[0027] Step (1): Dissolve 11.21g (0.0575mol) of phenylphosphoryl dichloride in 35ml of tetrahydrofuran solvent and slowly add dropwise to 23g (0.0575mol) of polyether (ester) polyol with an average molecular weight of 400 and 5.82g ( 0.0575mol) in 35ml tetrahydrofuran solvent of triethylamine, stirring at 0°C to complete the dropwise addition process;

[0028] Step (2): After the dropwise addition, raise the temperature to 40°C, and continue stirring for 6 hours;

[0029] Step (3): After the reaction is over, the phosphorus-based block flame-retardant polyether is obtained through vacuum distillation;

[0030] Step (4): 20 parts of expandable graphite, 60 parts of magnesium hydroxide, 10 parts of water, 6 parts of catalyst, 10 parts of foam stabilizer and 100 parts of phosphorus-based block flame-retardant polyether and polyether (ester) polyol The mixture is mixed (10 parts of phosphorus-based block flame-retardant polyether, 90 parts of polyether (ester) polyol), and stirre...

Embodiment 2

[0033] Step (1): Dissolve 12.13g (0.0575mol) of phenyl phosphate dichloride in 30ml of 1,4-dioxane solvent and slowly add dropwise to 23g (0.115mol) of polyether polyol with an average molecular weight of 200 and 11.64g (0.115mol) of triethylamine in 35ml of 1,4-dioxane solvent, stirring at 20°C to complete the dropwise addition process;

[0034] Step (2): After the dropwise addition, raise the temperature to 65°C, and continue stirring for 12 hours;

[0035] Step (3): After the reaction is over, the phosphorus-based block flame-retardant polyether is obtained through vacuum distillation;

[0036] Step (4): 50 parts of expandable graphite, 60 parts of aluminum hydroxide, 20 parts of water, 10 parts of catalyst, 12 parts of foam stabilizer and 100 parts of phosphorus-based block flame-retardant polyether and polyether (ester) polyol The mixture is mixed (20 parts of phosphorus-based block flame-retardant polyether, 80 parts of polyether (ester) polyol), and stirred evenly at r...

Embodiment 3

[0039] Step (1): Dissolve 8.70g (0.06mol) of vinylphosphonyl chloride in 20ml of N,N-dimethylformamide solvent and slowly add dropwise to 7.2g (0.072mol) of polyether polyol with an average molecular weight of 100 and 8.29g (0.06mol) of potassium carbonate in 25ml of N,N-dimethylformamide solvent, stirring at 30°C to complete the dropwise addition process;

[0040] Step (2): After the dropwise addition, the temperature is still maintained at 30°C, and the reaction is continued for 4 hours with stirring;

[0041] Step (3): After the reaction is over, the phosphorus-based block flame-retardant polyether is obtained through vacuum distillation;

[0042] Step (4): 100 parts of expandable graphite, 15 parts of aluminum hydroxide, 15 parts of magnesium hydroxide, 25 parts of n-pentane, 1 part of catalyst, 15 parts of foam stabilizer and 100 parts of phosphorus-based block flame-retardant polyether Mix with polyether (ester) polyol mixture (30 parts of phosphorus-based block flame-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com