Method for forging step shaft with electroslag ingots

A technology of electroslag ingots and stepped shafts, applied in the field of forging, can solve the problems of low utilization rate of forgings, increase of production cost, waste of materials, etc., and achieve the effect of improving utilization rate and enterprise production cost, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] The inventive method comprises the following steps:

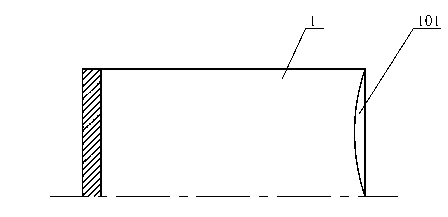

[0020] The first step: if Figure 4 As shown, the electroslag ingot 1 with the riser end 101 is placed on the upset drain plate 2 .

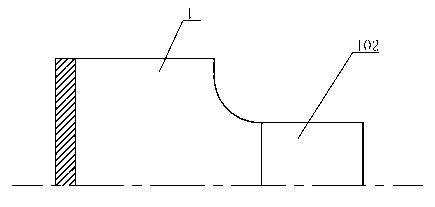

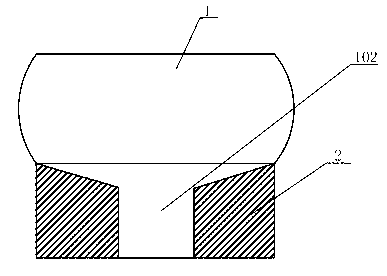

[0021] Step 2: Use a hydraulic machine to upset the electroslag ingot 1. Since the upsetting drain plate 2 is provided with an inner concave surface, after the electroslag ingot 1 is upset by the hydraulic machine, the riser end 101 of the electroslag ingot 1 is upset After that, a drum-shaped convex surface is formed, and the drum-shaped convex surface is as Figure 5 shown.

[0022] Step 3: Use the jaws of the manipulator to hold the electroslag ingot described in step 2, and elongate the electroslag ingot. Since the riser end of the electroslag ingot is a drum-shaped end face, it will not be stretched during the elongation process. produce s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com