Manufacturing process of wood door and half drying machine

A manufacturing process and technology for wooden doors, applied to door leaves, devices for coating liquid on the surface, and surface pretreatment, etc., can solve problems such as peeling and layering of paint on the door surface, cracks on the paint surface, long production cycle, etc., to solve fading and Chromatic aberration problem, full paint film without orange peel, high paint film flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

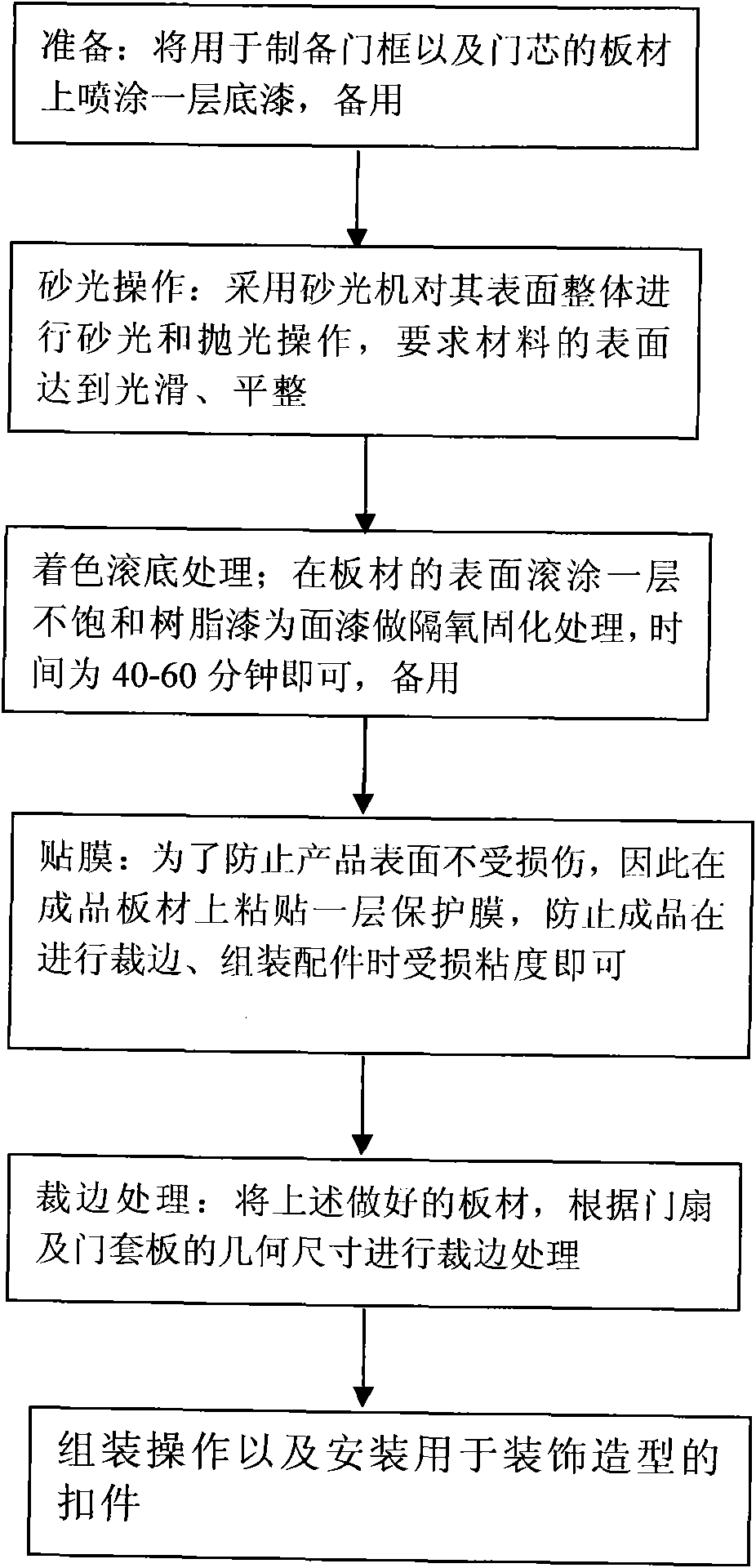

Embodiment approach 1

[0038] 1) Preparation: Spray a layer of primer on the plates used to prepare the door frame and door core, and set aside;

[0039] 2) Sanding operation: Use a sanding machine to sand and polish the surface as a whole, and the surface of the material is required to be smooth and flat;

[0040] 3) Coloring and rolling bottom treatment; roll coating a layer of unsaturated resin paint on the surface of the board as the top coat for oxygen barrier curing treatment, the time is 40-60 minutes, and the unsaturated resin paint can be operated with PV paint and UV paint ,spare;

[0041] 4) Film: In order to prevent the surface of the product from being damaged, a protective film is pasted on the finished plate to prevent the finished product from being damaged when trimming and assembling accessories;

[0042] 5) Edge trimming: trim the above-mentioned finished panels according to the geometric dimensions of the door leaf and the door cover;

[0043] 6) Assembling operation: glue and ...

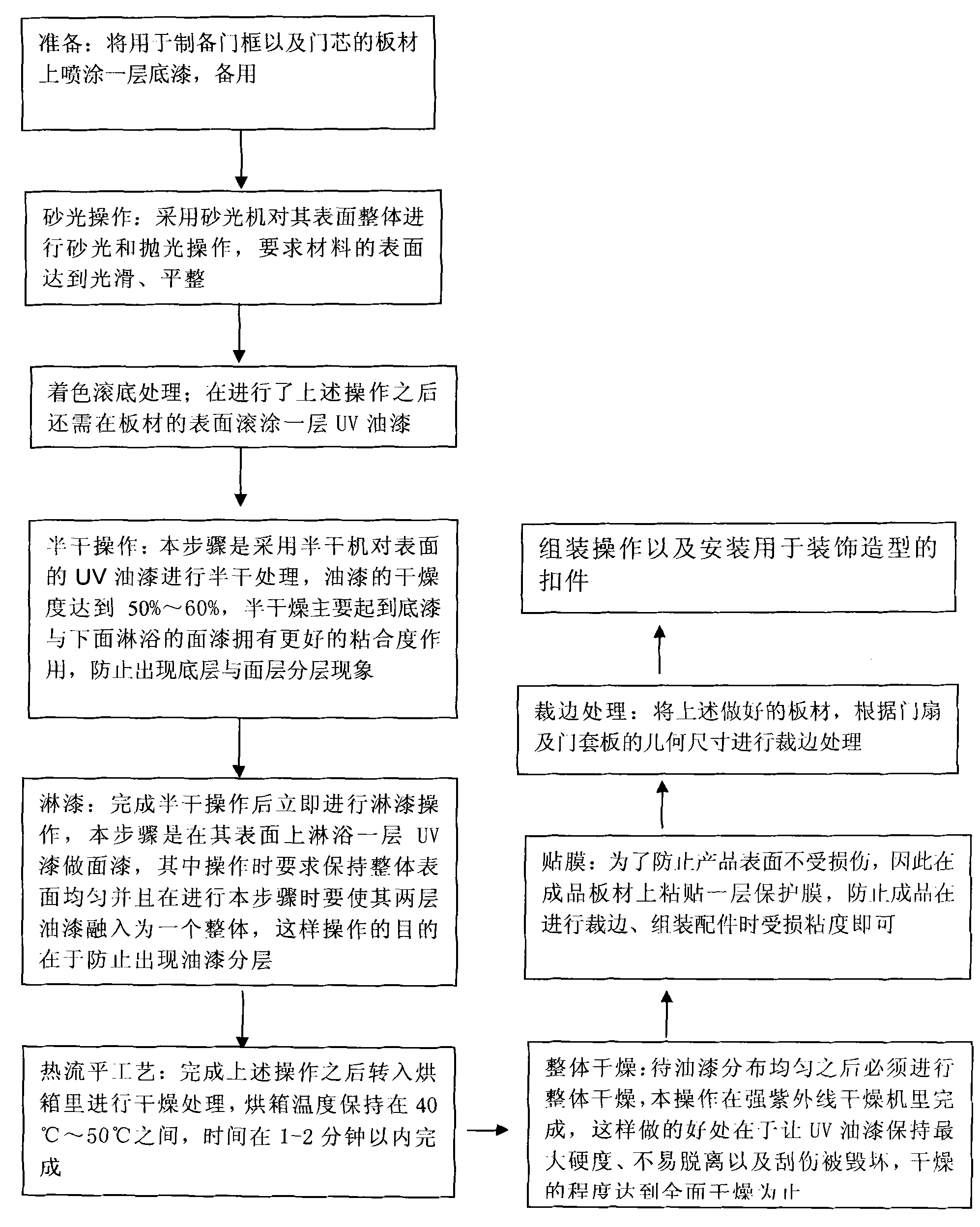

Embodiment approach 2

[0046] However, in the production process, the detailed treatment of the paint is often neglected. Due to improper handling of the paint, the paint on the surface of the produced door often peels off and delaminates, which seriously affects the appearance and use. In order to solve these problems the present invention also provides a kind of improvement on above-mentioned technology basis, and its specific technology is:

[0047] 1) Preparation: Spray a layer of resin paint on the board used to prepare the door frame and door core as an oxygen-barrier curing primer, such as unsaturated resin paint, and then dry it for 40-60 minutes. Standby;

[0048] 2) Sanding operation: use a sanding machine to sand and polish the surface as a whole, and the surface of the material is required to be smooth and flat;

[0049] 3) coloring and rolling bottom treatment; after the above operations, it is necessary to roll one layer of UV paint on the surface of the plate as a primer;

[0050] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com