Functional modified diaphragm as well as preparation method and application thereof

A functional and diaphragm technology, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as poor rate and cycle performance, poor electrolyte retention capacity, and polyolefin diaphragms that cannot absorb electrolyte well. Achieve the effects of strong liquid absorption and liquid retention, low price, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Preparation of a functionalized modified diaphragm and its application in lithium-ion batteries

[0063] Preparation of functionalized modified separator:

[0064] Prepare a pH buffer solution: use water / ethanol with a volume ratio of 1:1 as a solvent to prepare a 10 mmol / L tris / hydrochloric acid pH buffer solution with a pH of 8.5.

[0065] Preparation of mixed monomer polymerization precursor solution: dissolving catechol in the prepared pH buffer solution to prepare a 20 mmol / L solution. The molar ratio is: catechol / tetraethylenepentamine=4 / 1, and a certain amount of tetraethylenepentamine is added. Thoroughly stir, dissolve and mix to prepare a mixed monomer polymerization precursor.

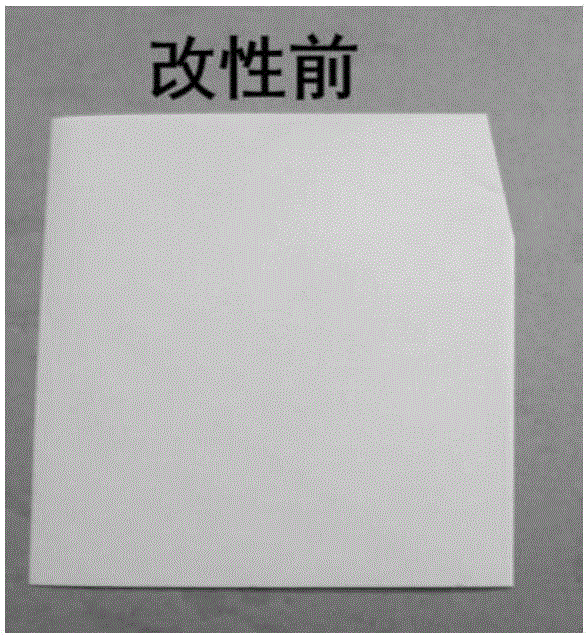

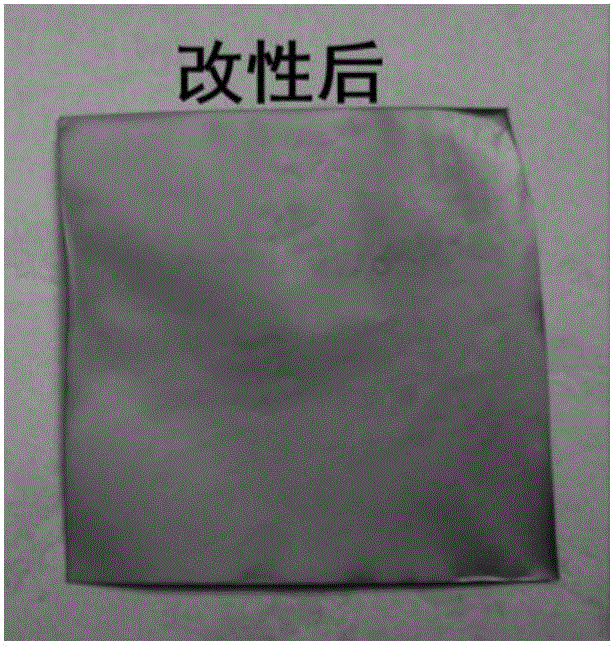

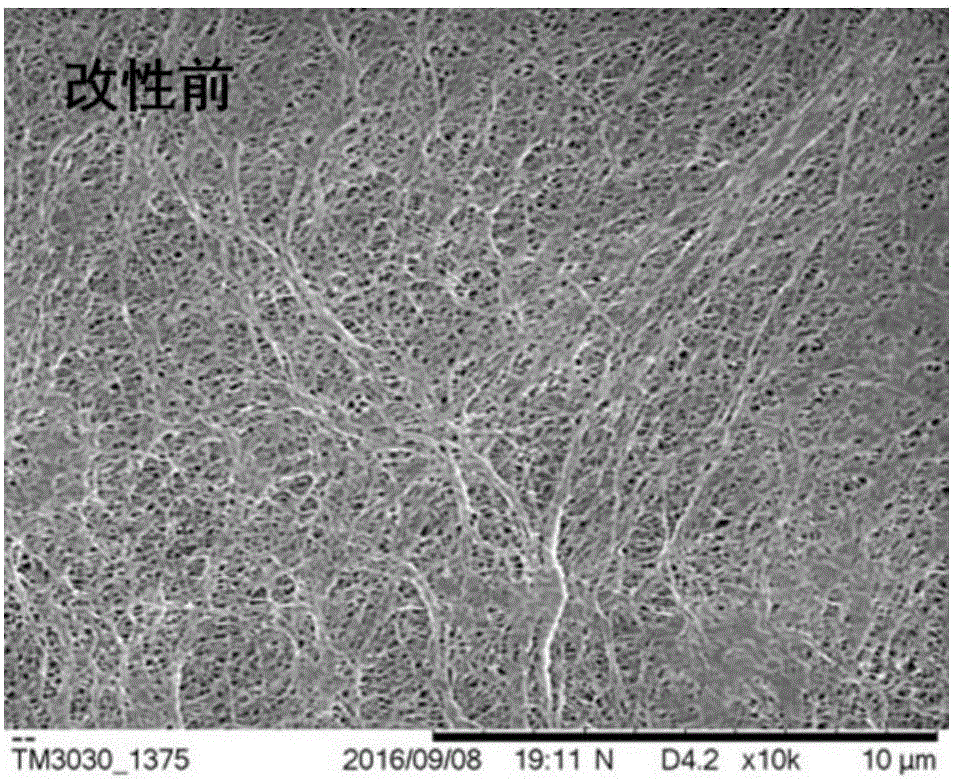

[0066] Preparation of functionalized modified diaphragm: 100cm 2 Immerse in 50mL mixed monomer polymerization precursor solution, and soak and react at room temperature for 24h under the condition of oxygen flow. Afterwards, the diaphragm was pulled out, washed repeated...

Embodiment 2

[0074] Example 2: Preparation of a functionalized modified diaphragm and its application in lithium-ion batteries

[0075] Preparation of functionalized modified separator:

[0076] Prepare a pH buffer solution: use water / methanol with a volume ratio of 1:1 as a solvent to prepare a 10 mmol / L tris / hydrochloric acid pH buffer solution with a pH of 10.

[0077] Preparation of mixed monomer polymerization precursor: 3-methylcatechol was dissolved in the prepared pH buffer solution to prepare a 400 mmol / L solution. The molar ratio is: 3-methylcatechol / polyethyleneimine (molecular weight: 600)=10 / 1, and quantitative polyethyleneimine (molecular weight: 600) is added. Thoroughly stir, dissolve and mix to prepare a mixed monomer polymerization precursor.

[0078] Preparation of functionalized modified diaphragm: the polypropylene (PP) diaphragm sample (that is, the organic diaphragm substrate to be modified) was 2 Immerse in 50mL mixed monomer polymerization precursor solution, an...

Embodiment 3

[0083] Example 3: Preparation of a functionalized modified diaphragm and its application in lithium-ion batteries

[0084] Preparation of functionalized modified separator:

[0085] Prepare a pH buffer solution: use water / dimethylacetamide with a volume ratio of 1:1 as a solvent to prepare a 10 mmol / L tris / hydrochloric acid pH buffer solution with a pH of 12.

[0086] Prepare mixed monomer polymerization precursor solution: dissolve tannic acid in the prepared pH buffer solution to make a 2 mmol / L solution. The molar ratio is: tannic acid / p-methylphenethylamine=1 / 5, and a quantitative amount of p-methylphenethylamine is added. Thoroughly stir, dissolve and mix to prepare a mixed monomer polymerization precursor.

[0087] Preparation of functionalized modified diaphragm: Scrape-coat 500mL of mixed monomer polymerization precursor solution on 1m 2 The surface of the polyvinyl chloride diaphragm sample (that is, the organic diaphragm substrate to be modified) is placed in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com