Battery, capacitor diaphragm and preparation method of battery and capacitor diaphragm

A technology for capacitors and diaphragms, which is applied in the field of capacitor diaphragms and their preparation, and batteries. It can solve the problems of difficulty in controlling the pore size and porosity of supercapacitor diaphragms, the inability to achieve single-sided coarsening of the diaphragm, and the difficulty in controlling the sizing process. Soft, strong and tough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

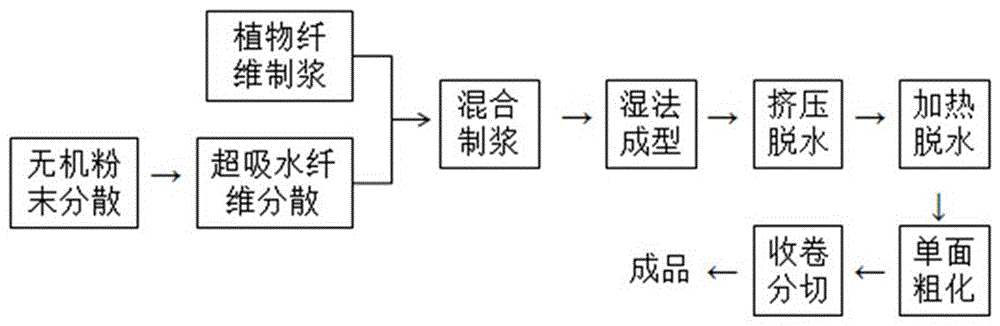

Method used

Image

Examples

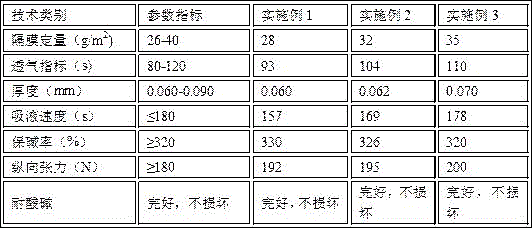

Embodiment 1

[0041] A kind of battery, capacitor diaphragm, according to diaphragm finished product weight 1000Kg, the various raw material weights in the preparation raw material are as follows:

[0042] Sulfite wood pulp 650Kg, SAF super absorbent fiber 200Kg, attapulgite powder 100Kg, chitosan 5Kg, hydrogen storage material ZnO 2 15 Kg, the synthetic fiber is a mixture of polypropylene fiber and polyvinyl alcohol fiber, of which 15Kg is polypropylene fiber and 15Kg is polyvinyl alcohol fiber.

[0043] The preparation method of above-mentioned a kind of battery, capacitor separator, the steps are:

[0044] Plant fiber pulping: beat and disperse sulfite wood pulp and water with a beater at a concentration of 10% to obtain plant fiber slurry for later use;

[0045] ⑵Inorganic powder dispersion: mix attapulgite powder, chitosan and water into a 10% concentration suspension to prepare an inorganic powder suspension for later use;

[0046] (3) Superabsorbent fiber dispersion: the inorganic...

Embodiment 2

[0054] A kind of battery, capacitor diaphragm, according to diaphragm finished product weight 1000Kg, the various raw material weights in the preparation raw material are as follows:

[0055] Sulfite wood pulp 700Kg, SAF super absorbent fiber 150Kg, attapulgite powder 100Kg, chitosan 10Kg, hydrogen storage material ZnO 2 10Kg, the synthetic fiber is a mixture of polypropylene fiber and polyvinyl alcohol fiber, of which 15Kg is polypropylene fiber and 15Kg is polyvinyl alcohol fiber.

[0056] The preparation method of above-mentioned a kind of battery, capacitor separator, the steps are:

[0057] Plant fiber pulping: beat and disperse sulfite wood pulp and water with a beater at a concentration of 12% to obtain plant fiber slurry for subsequent use;

[0058] ⑵Inorganic powder dispersion: mix attapulgite powder, chitosan and water to form a 12% concentration suspension to prepare an inorganic powder suspension for later use;

[0059] (3) Superabsorbent fiber dispersion: the...

Embodiment 3

[0067] A kind of battery, capacitor diaphragm, according to diaphragm finished product weight 1000Kg, the various raw material weights in the preparation raw material are as follows:

[0068] Sulfite wood pulp 750Kg, SAF super absorbent fiber 100Kg, attapulgite powder 100Kg, chitosan 8Kg, hydrogen storage material ZnO 2 12Kg, the synthetic fiber is a mixture of polypropylene fiber and polyvinyl alcohol fiber, of which 15Kg is polypropylene fiber and 15Kg is polyvinyl alcohol fiber.

[0069] The preparation method of above-mentioned a kind of battery, capacitor separator, the steps are:

[0070] Plant fiber pulping: beat and disperse sulfite wood pulp and water with a beater at a concentration of 15% to obtain plant fiber slurry for subsequent use;

[0071] ⑵Inorganic powder dispersion: mix attapulgite powder, chitosan and water to form a 15% concentration suspension to prepare an inorganic powder suspension for later use;

[0072] (3) Superabsorbent fiber dispersion: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com