Preparation of polymer solid electrolyte

A solid electrolyte and polymer technology, which is applied in the field of preparation of functional polymer materials, can solve the problems of difficulty in forming a gel-type polymer electrolyte, complicated film-making process, volatile electrolyte, etc., and achieves overcoming the difficulty in forming and simple operation. , Overcome the volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

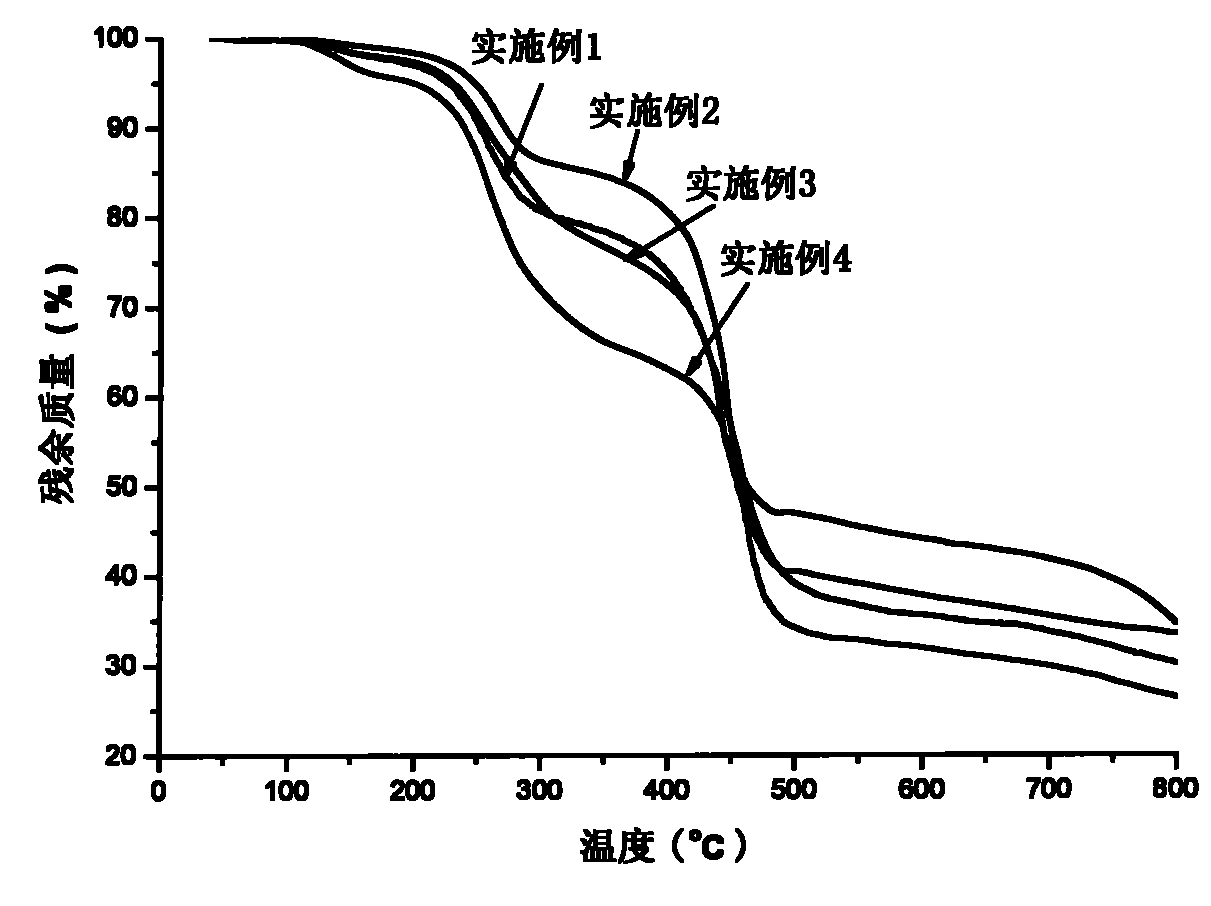

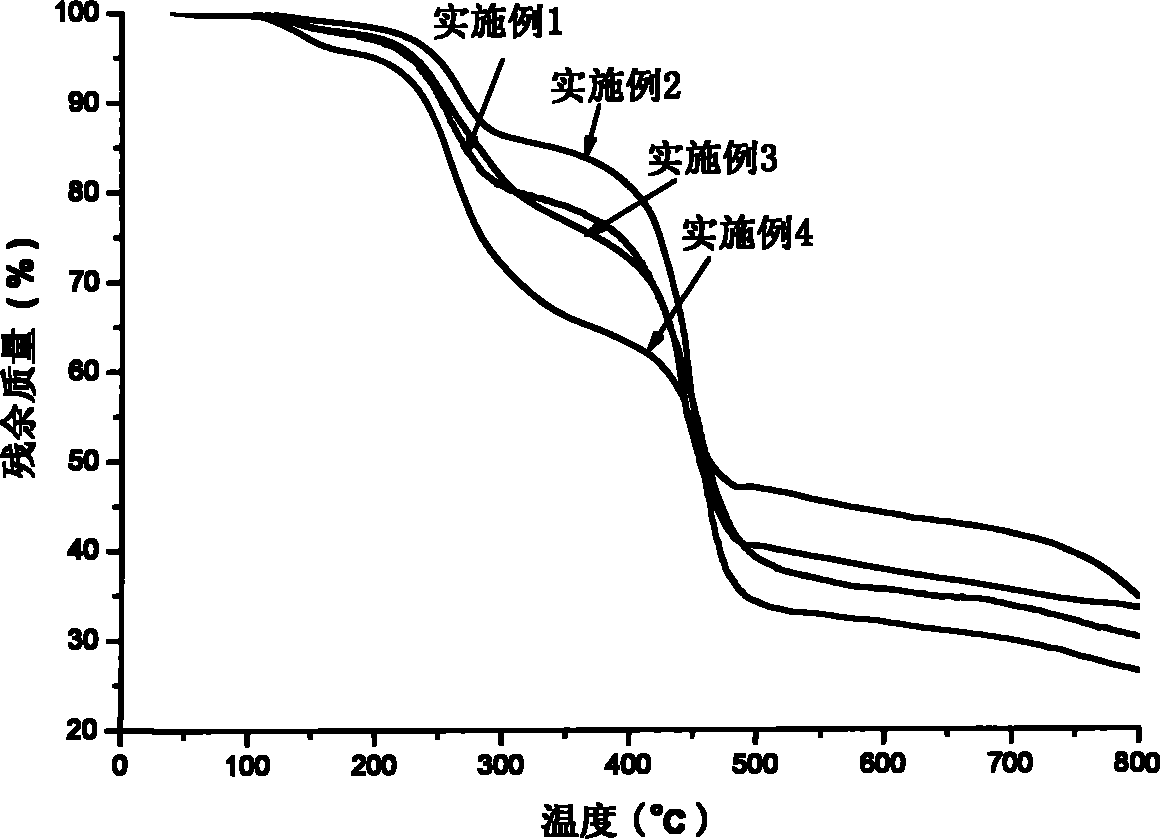

[0026] Embodiments 1 to 4: Dissolve nitrile rubber in 25 parts of methyl ethyl ketone according to the formula in Table 1, add 25 parts of methanol to the resulting homogeneous solution, precipitate the nitrile rubber, then wash it repeatedly with methanol and place it in a vacuum at 45°C Dry in an oven for 24 hours to remove residual solvent to obtain purified and dried nitrile rubber; add the purified and dried nitrile rubber, epoxy resin and lithium perchlorate into tetrahydrofuran, place it at room temperature for 6 hours, and then magnetically stir for 15 minutes. Obtain a uniform transparent viscous solution, pour it into a polytetrafluoroethylene mold, evaporate the solvent, and dry it in vacuum to obtain a polymer solid electrolyte. The conductivity value of the obtained polymer solid electrolyte is shown in Table 2, and the obtained polymer solid electrolyte is subjected to thermogravimetric analysis, and the results are shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com