Patents

Literature

41results about How to "Easy to cut and shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

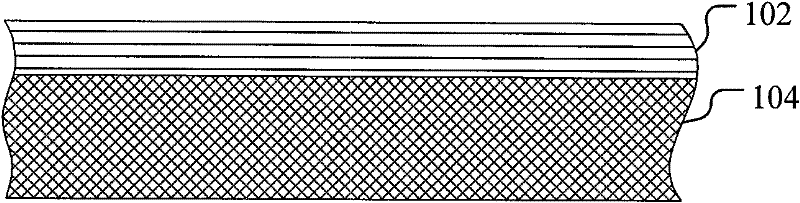

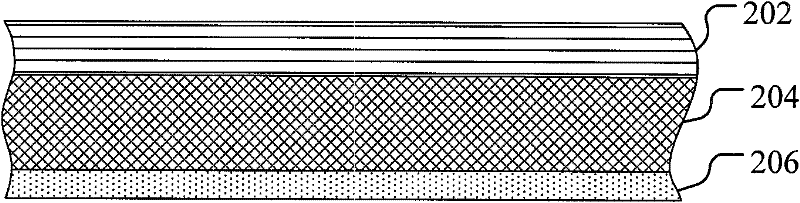

Building sheet material and its manufacture method

InactiveCN102337770AMoisture-proofImprove mildew resistanceConstruction materialCovering/liningsEcological environmentMoisture resistance

The invention provides a building sheet material and a manufacture method for solving the problems of the current building sheet materials which are easy to be wetted, corroded and deformed. According to an enforcement of the present invention, the building sheet material comprises a cement plate layer and a magnesium oxide plate layer. The building sheet material of the present invention employs a composite structure of a cement plate and a magnesium oxide plate or a wood plate, which has the advantages of moisture resistance, mildew resistance, fire resistance, corrosion resistance, sound insulation effect and difficult deformation. The building sheet material of the present invention uses a firm cement plate layer as an exposed surface, and has good durable performance. In addition, because the usage of wood material is reduced, the building sheet material influence on ecological environment can be effectively reduced.

Owner:上海亮世国际贸易有限公司

Ready-to-eat flavored fish skin and preparation method thereof

The invention provides ready-to-eat flavored fish skin and a preparation method thereof. The preparation method comprises the following technology steps: (1) macerating fish skin in wine: adding an edible alcohol solution of which the mass is 20-40% as much as the mass of the fish skin and of which the volume concentration is 60-90% to pretreated fish skin; uniformly stirring the pretreated fish skin and the edible alcohol solution so as to obtain a mixture; and placing the mixture in a sealing manner at a room temperature for 30-60 minutes, and then draining the edible alcohol solution so as to obtain wine-macerated fish skin; (2) preserving the wine-macerated fish skin: adding preserving materials to the wine-macerated fish skin obtained in the step (1), and uniformly stirring the preserving materials and the wine-macerated fish skin so as to obtain a new mixture; and preserving the new mixture in a sealing manner at the temperature of 4-15 DEG C for 4-12 hours so as to obtain preserved fish skin; (3) baking the preserved fish skin: baking the preserved fish skin obtained in the step (2) at the temperature of 50-70 DEG C for 20-50 minutes, after baking, cooling the baked fish skin to be room temperature, and then processing the cooled fish skin into slices so as to obtain dried fish skin slices; (4) deep-frying the dried fish skin slices; and (5) removing oil from the deep-fried fish skin slices, seasoning the dried fish skin slices after oil removal, and packaging the seasoned dried fish skin slices. According to the method disclosed by the invention, original color and original nutrition of the fish skin can be reserved to the maximum extent, the mouth feel and the preservation property are improved, and the processing technology is simple and environmental-friendly.

Owner:SICHUAN UNIV

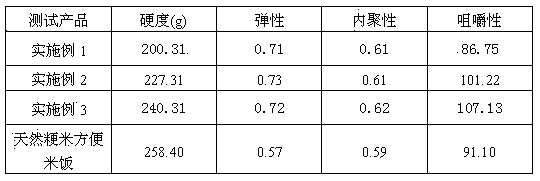

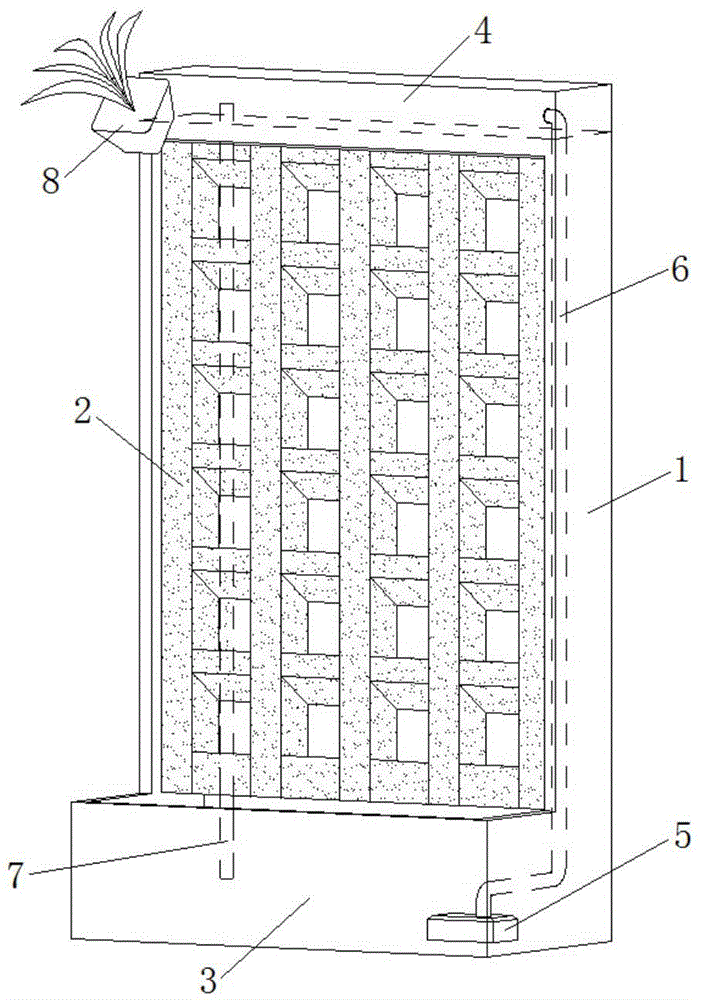

Preparation method of moisturizing instant rice

ActiveCN103519056ATraits that are easy to controlImprove adaptabilityFood thermal treatmentMulti-step food processesRice dishesBroken rice

The invention discloses a preparation method of moisturizing instant rice. By taking broken rice as a raw material, the moisturizing instant rice is prepared by the following steps: pre-cooking; drying; crushing; carrying out twin-screw extrusion; cutting and moulding; packaging; sealing; and sterilizing. In the pre-cooking step, the degree of gelatinization is controlled at 40-60%. In the drying step, the water content is controlled at 20-25%. According to the invention, the moisturizing instant rice is processed and prepared by adopting pre-cooking step combined with twin-screw extrusion, so that the moisturizing instant rice prepared is full in particle, glittering and translucent in color and luster, appropriate in hardness and chewiness and durable in storage, and the quality of the moisturizing instant rice is close to that of natural rice.

Owner:JIANGNAN UNIV

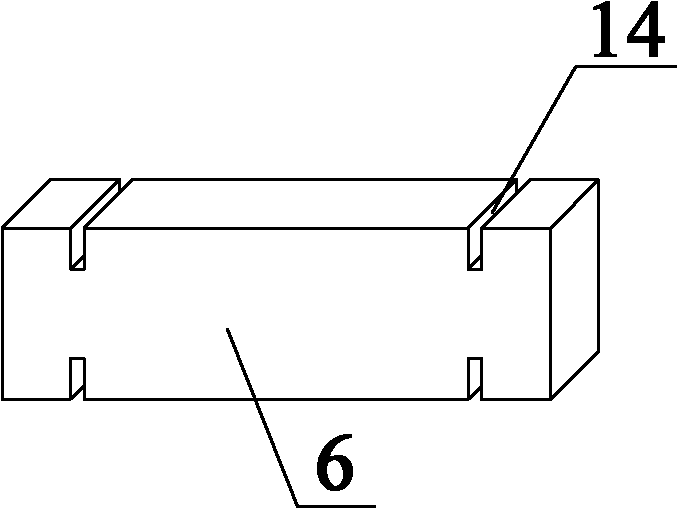

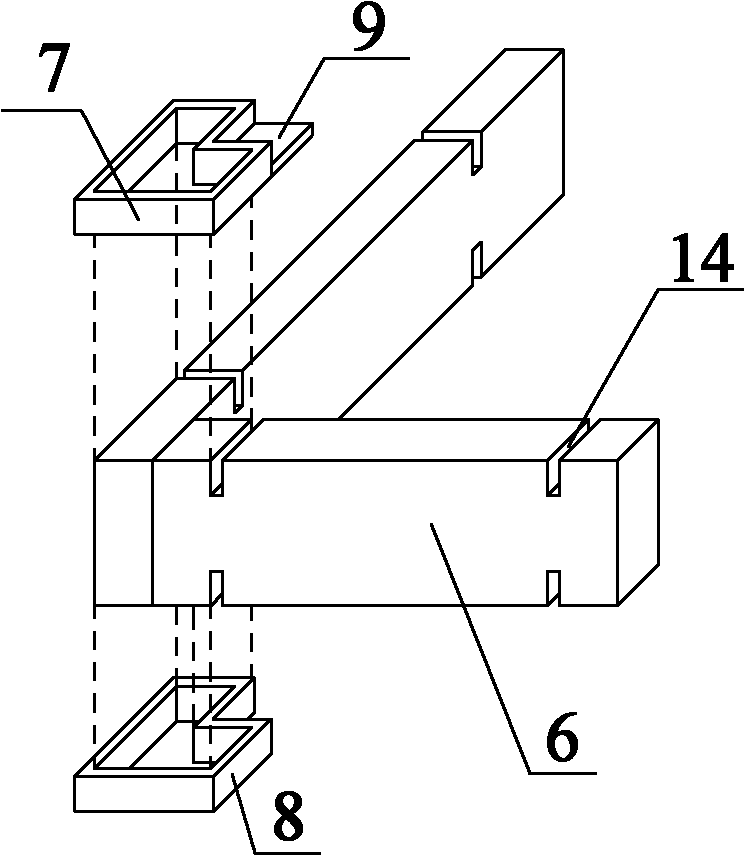

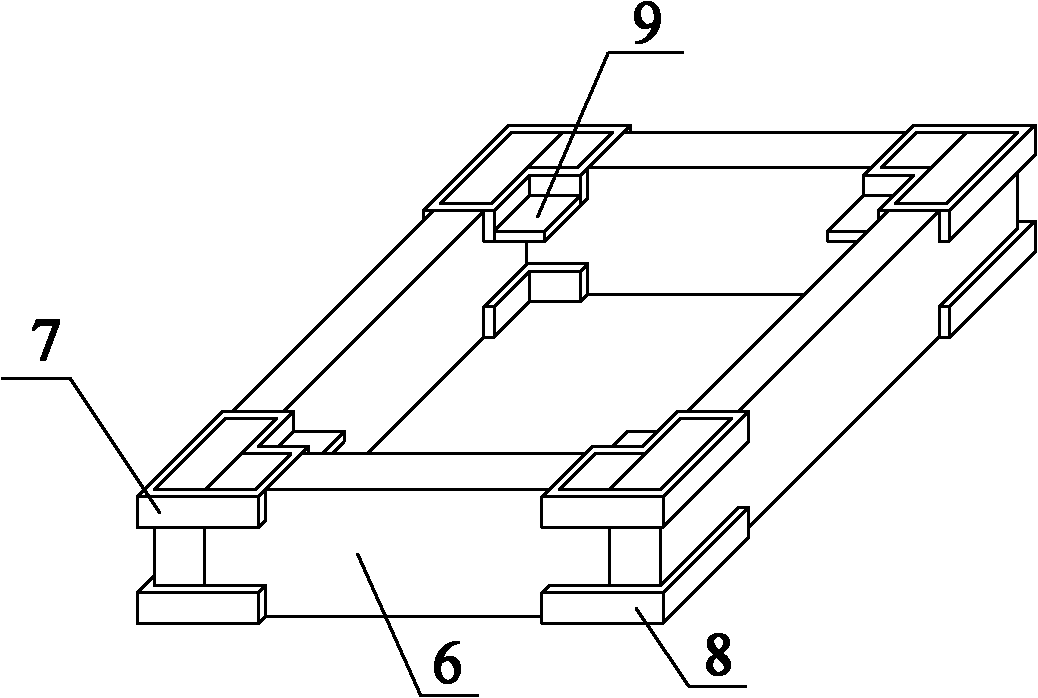

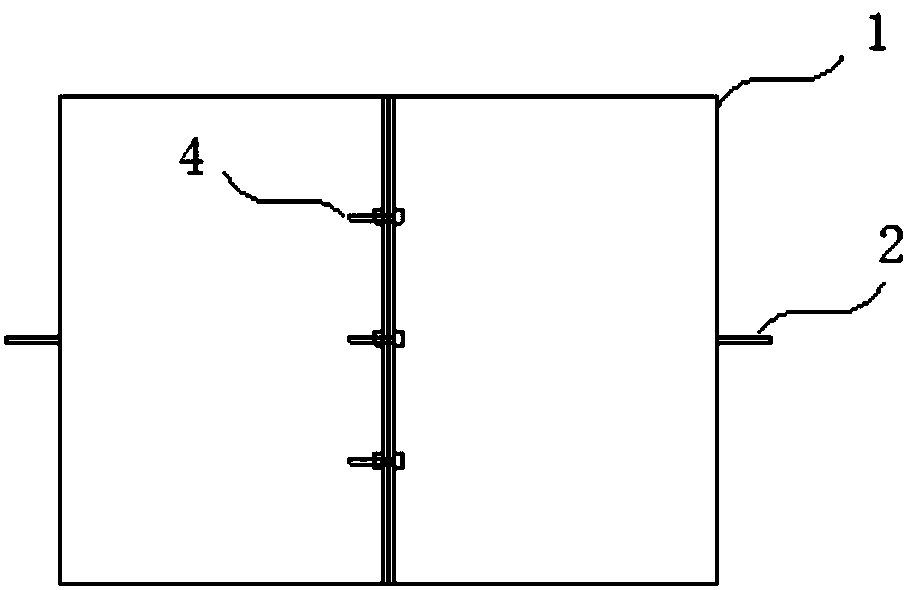

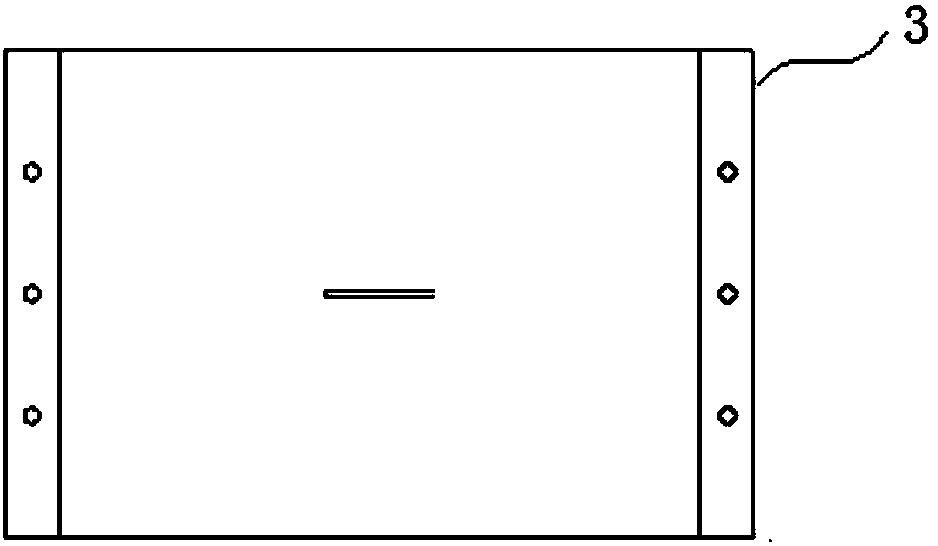

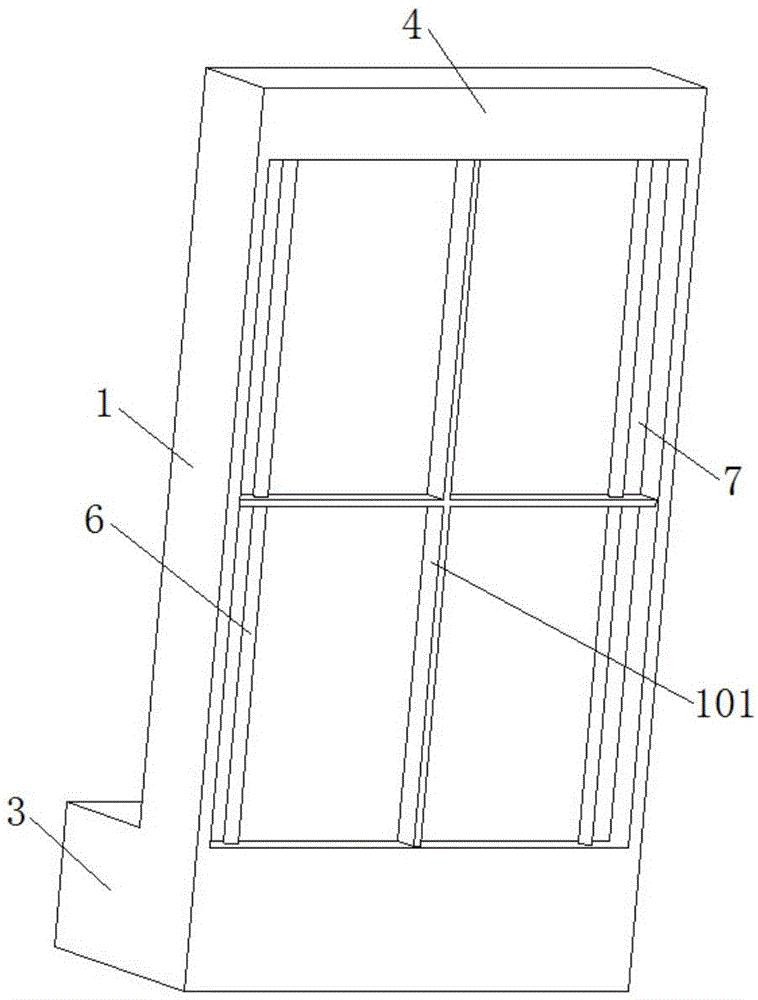

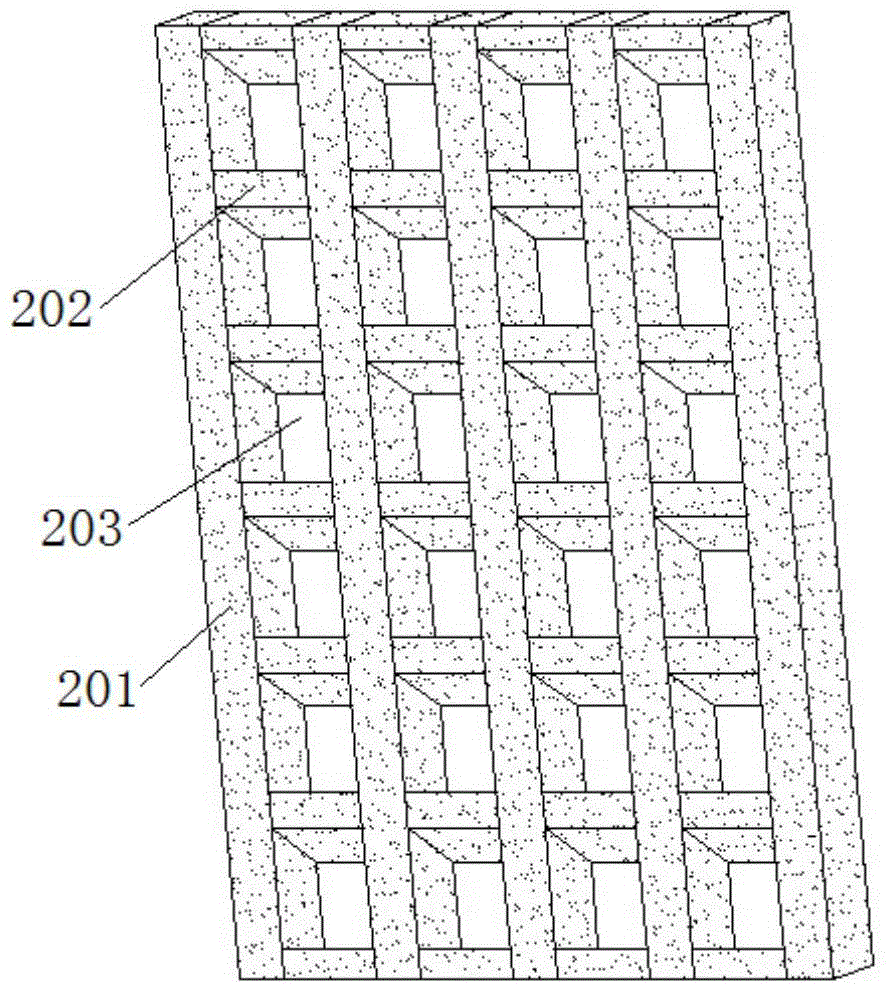

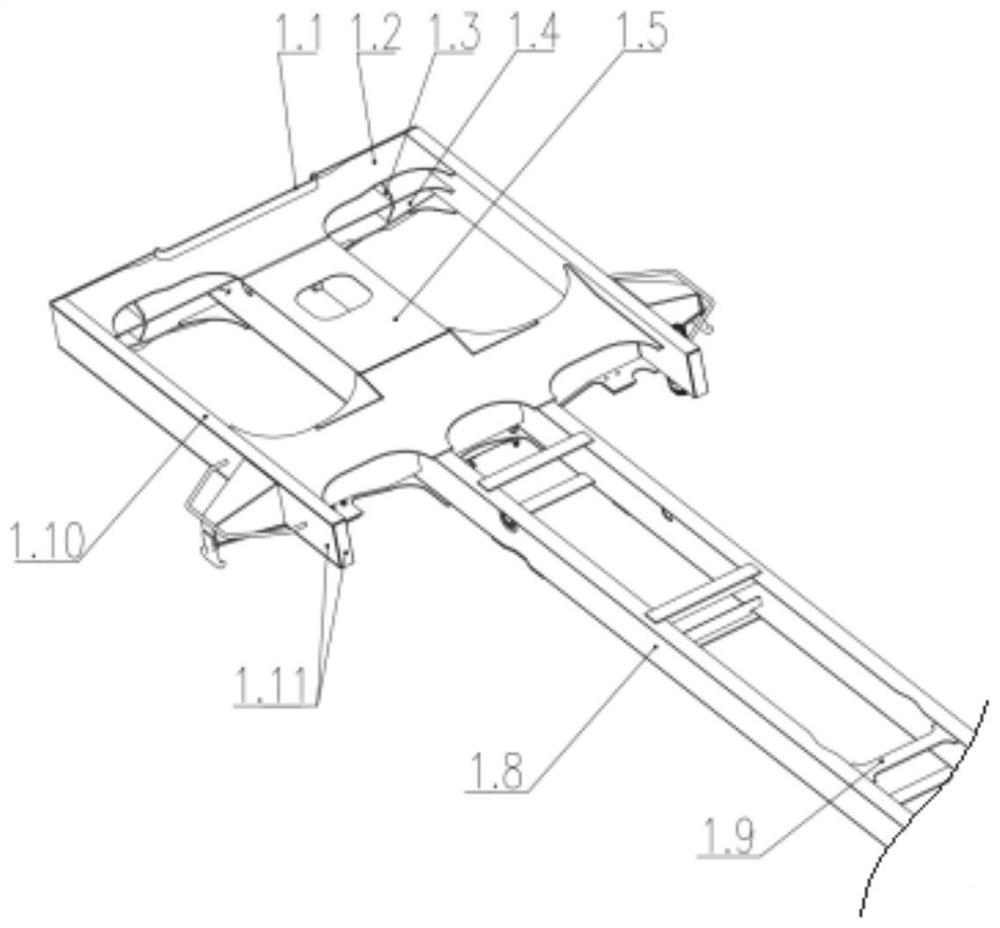

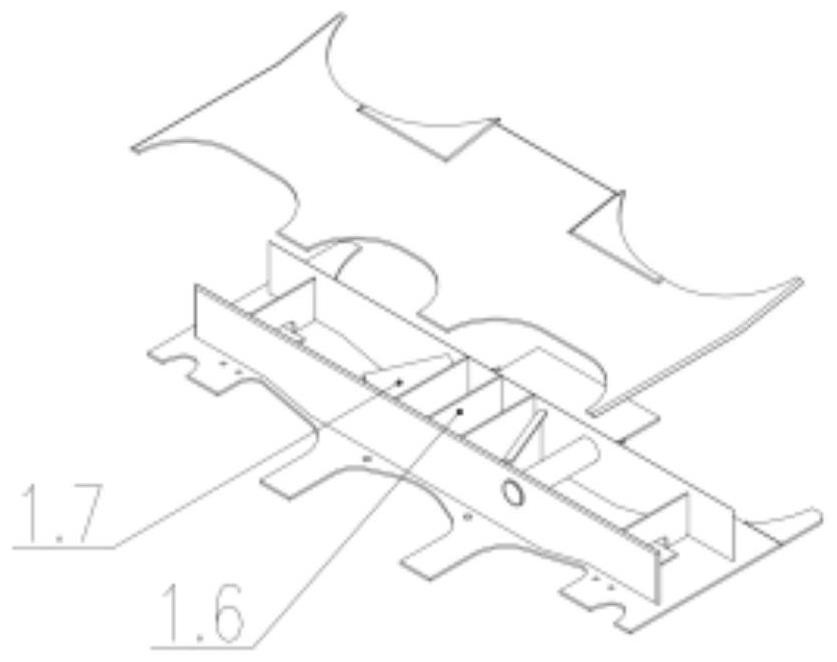

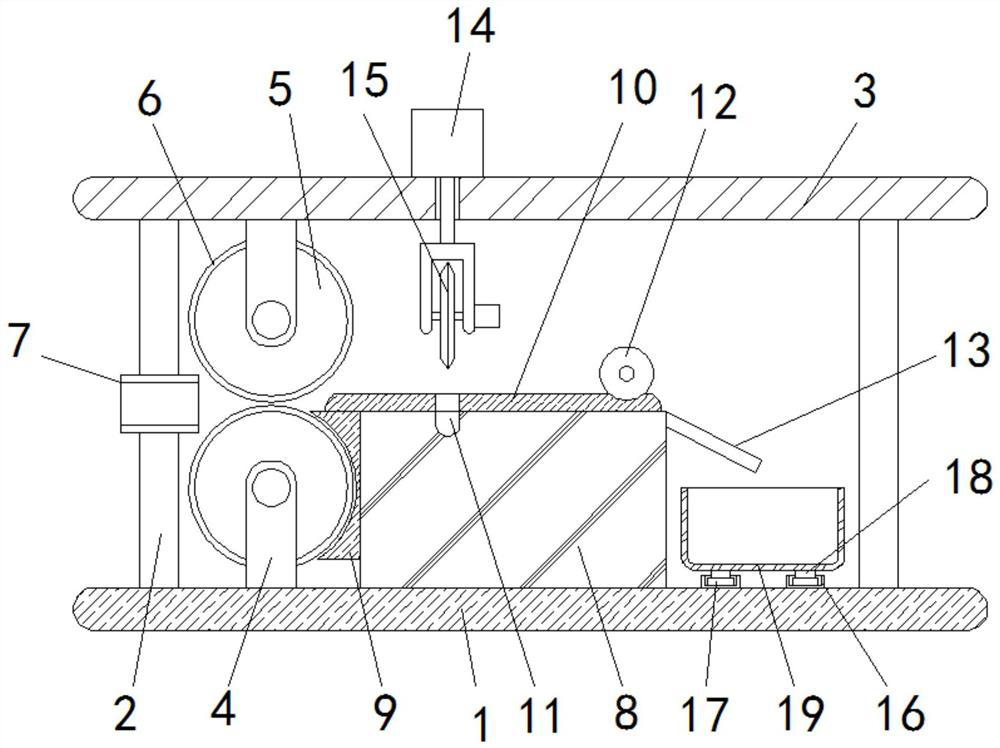

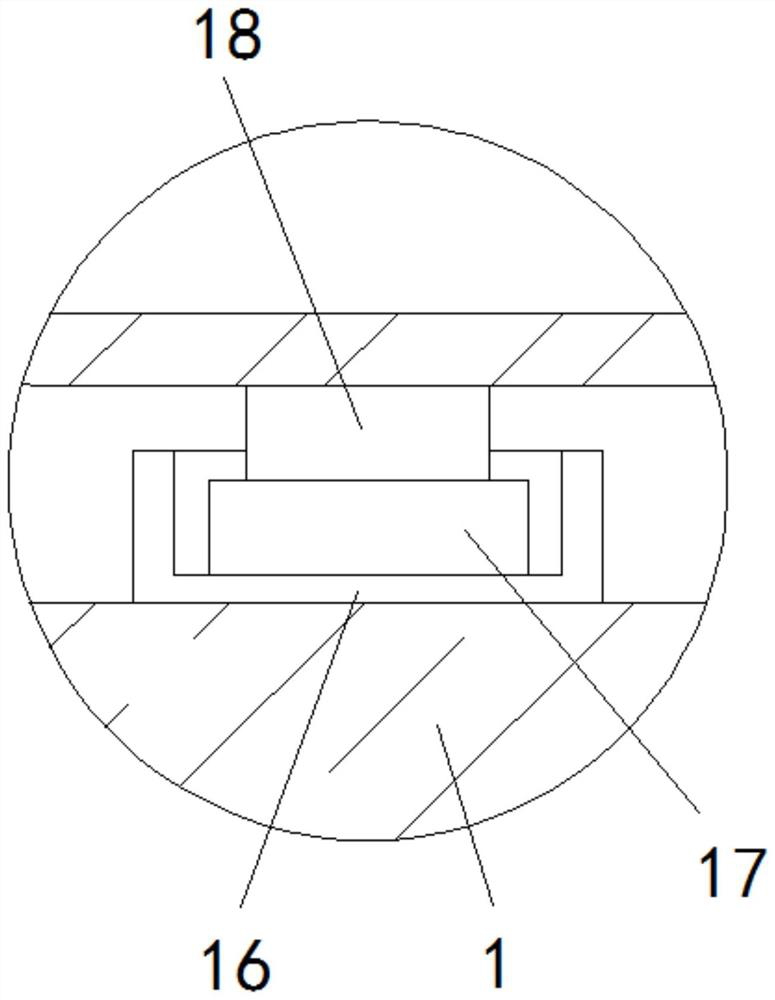

Reinforced concrete hollow floor plate

The invention discloses a reinforced concrete hollow floor plate, comprising reinforced concrete prefabricated construction members (1) and cast-in-place concrete (2), wherein each prefabricated construction member (1) is composed of a prefabricated base plate (3), a prefabricated side wall (4) and a prefabricated top plate (5), the prefabricated side wall (4) is formed by splicing two or more than two prefabricated plates (6) by virtue of a top connecting piece (7) and a bottom connecting piece (8), and the prefabricated top plate (5) is placed on a shelf piece (9) extending from the top connecting piece (7). When construction is carried out, a mouldboard (19) is erected firstly, a plurality of reinforced concrete prefabricated base plates (3) are arranged vertically and horizontally on the mouldboard (19), the prefabricated side wall is well assembled and is placed on the prefabricated base plate (3), then the prefabricated top plate is placed on the shelf piece (9) to form one prefabricated construction member (1), and a seam covering plate (11) is placed at the top of the prefabricated construction members (1). The cast-in-place concrete (2) is cast in the gap between the prefabricated construction members (1) which are arranged vertically and horizontally and at the top of the prefabricated construction members, and the prefabricated construction members (1) and the cast-in-place concrete (2) are cast into a whole, thus the reinforced concrete hollow floor plate is formed.

Owner:吴充

Method for automatically processing almond slices

ActiveCN103535796AFully soakedEasy to peelMulti-step food processesFood shapingMicrowaveFluidized bed

The invention relates to a method for processing nuts and in particular relates to a method for automatically processing almond slices. The method comprises the following steps: A. cleaning almonds to be processed by a nut cleaning device; B. carrying out rolling stewing on the cleaned almonds by a precooker; C. peeling the stewed almonds by a peeling machine; D. carrying out color sorting on the peeled almond pulps by a color sorter; E. carrying out microwave baking on the almond pulps by a microwave baker; F. cutting the almond pulps into almond slices by a slicing machine; G. carrying out vibratory screening on the cut almond slices by a vibrating screen; and H. drying and dehydrating the almond slices by a fluidized bed through high-temperature vapor being 160-190 DEG C. According to the method for automatically processing the almond slices, the efficiency is high, the cost is low, the qualification rate of the produced almond slices is high, and raw materials are saved.

Owner:东莞市绰士食品有限公司

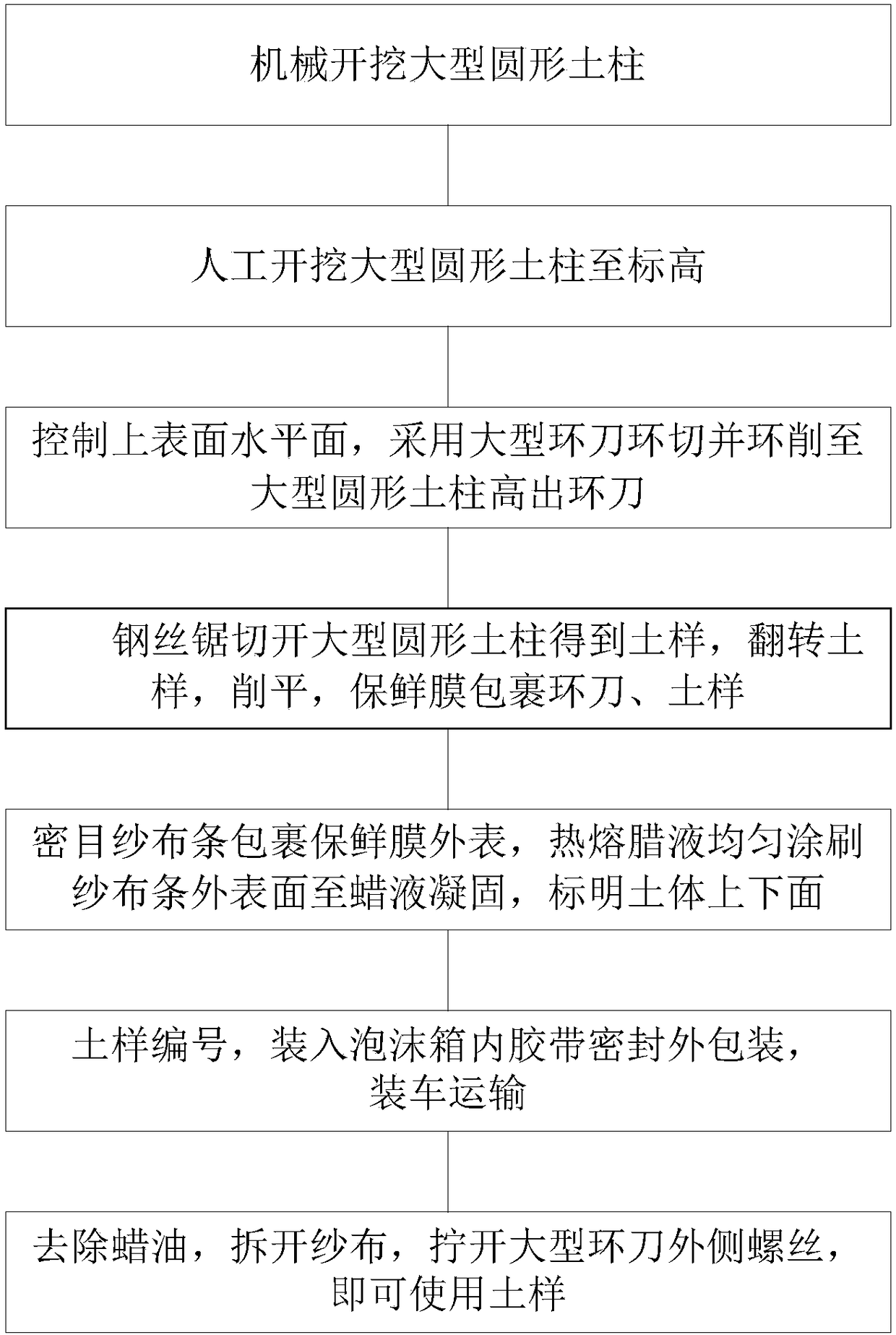

Large raw loess sampling method

ActiveCN108593341ASmall sizeReduce disturbanceWithdrawing sample devicesPreparing sample for investigationWaxSoil science

The invention discloses a large raw loess sampling method. The large raw loess sampling method comprises the following steps: determining a site of a to-be-sampled soil, mechanically excavating untilthe height reaches a large cylinder soil pillar, then manually excavating a large cylinder soil pillar to the elevation of the to-be-sampled soil; controlling a horizontal plane on the upper surface of the large cylinder soil pillar, using a large ring cutter to vertically press downwards, using a soil cutter to press and cut until the large cylinder soil pillar is higher than the ring cutter; using a steel wire saw to cut through the joint of the large cylinder soil pillar and the ground surface to obtain a soil sample, turning the soil sample, beveling the lower part, using a preservative film to wrap the whole soil sample together with the large ring cutter; wrapping with a dense mesh ribbon gauge, evenly brushing a hot melt wax liquid until the wax liquid is solidified, marking the upper surface and the lower surface of a soil body; numbering the soil sample, packaging in a foam box, sealing a paper box with an adhesive tape, loading on a truck, and transporting; removing wax oil,dismounting the gauge, and unscrewing a screw. The method does not change the stress state of the soil body, and disturbance can be avoided. The obtained soil sample meets the requirements of large-size mechanical test on size of the soil sample, the disturbance degree, and the maintenance of the physical mechanical property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

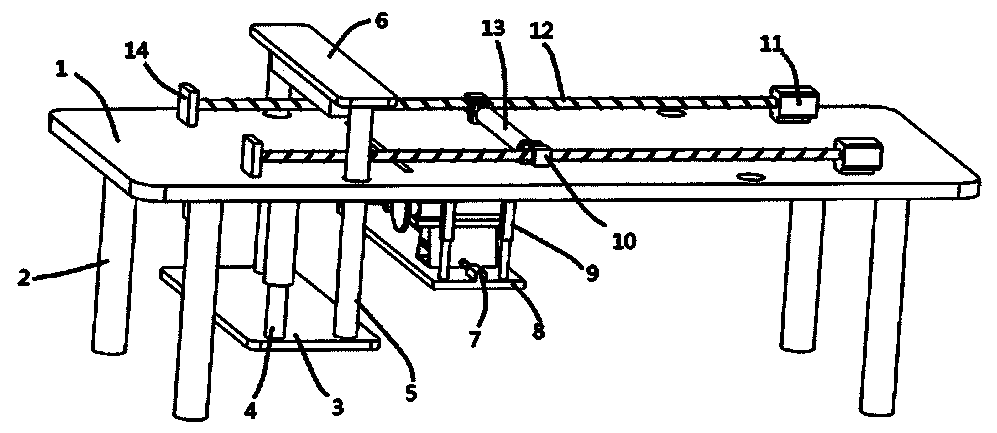

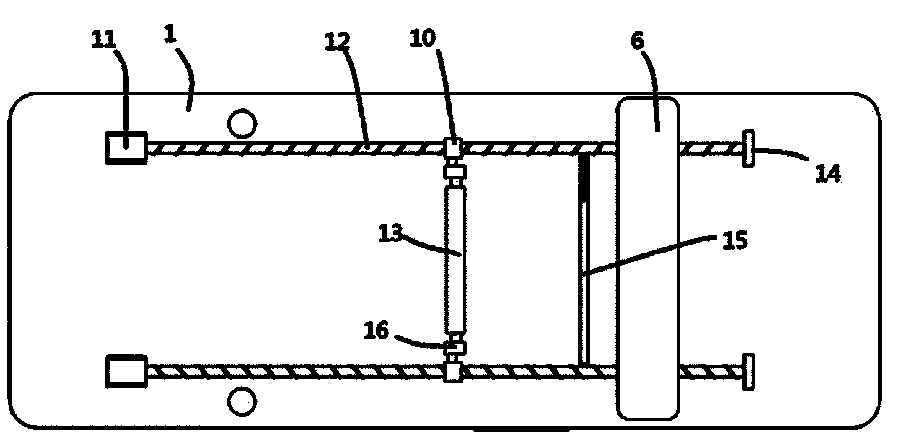

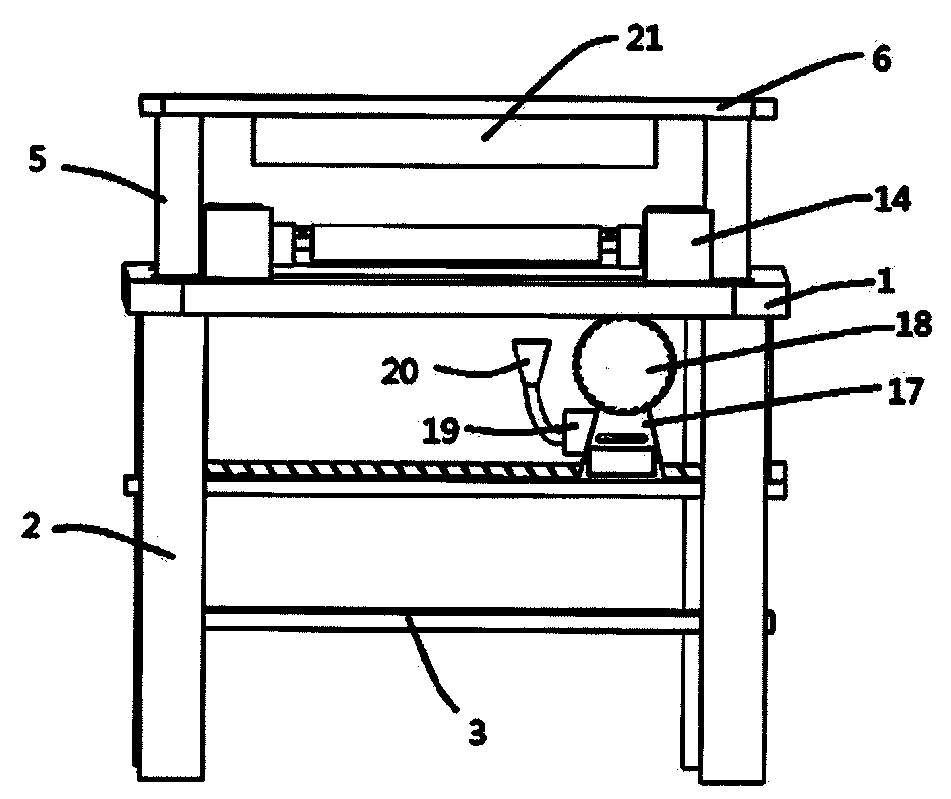

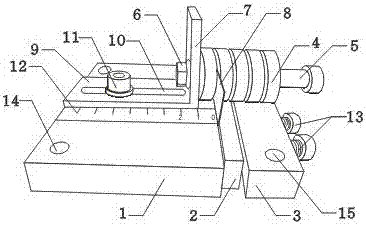

Building brick shape-fixing cutting equipment

InactiveCN108189247ALow costEasy to useWorking accessoriesStone-like material working toolsBrickFixed frame

The invention discloses building brick shape-fixing cutting equipment. The building brick shape-fixing cutting equipment comprises an installation seat; the two ends of the upper surface of the installation seat are fixedly connected with a pair of L-shaped positioning plates; the upper surface of each L-shaped positioning plate is fixedly connected with a fixed pressing plate; the upper surface of the installation seat is fixedly connected with an electrically-controlled telescopic door-shaped frame; the lower surface of a transverse beam of the electrically-controlled telescopic door-shapedframe is fixedly connected with a transverse slide rail; an electrically-controlled movable slide block is arranged on the lower surface of the transverse slide rail, and the lower surface of the electrically-controlled movable slide block is fixedly connected with a door-shaped fixed frame; installation holes are machined in supporting legs of the door-shaped fixed frame, and a cutting motor of which the driving end is in the horizontal direction is embedded in one of the installation holes; the rotary end of the cutting motor is fixedly connected with a connection shaft stretching out through the other installation hole, and the connection shaft is sleeved with a cutting saw web. The building brick shape-fixing cutting equipment has the beneficial effects of being simple in structure andhigh in practicality.

Owner:魏敏生

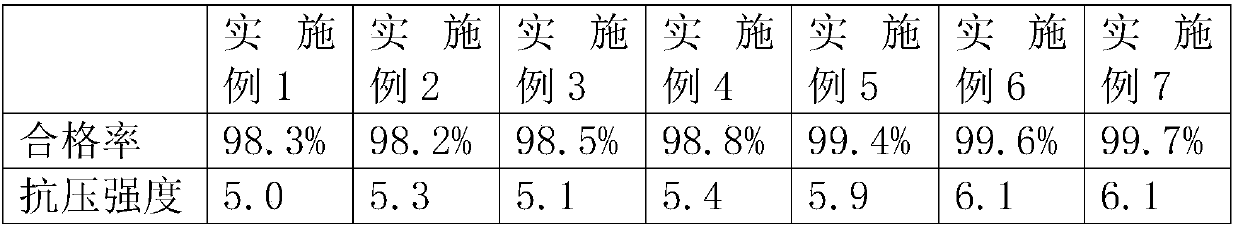

Aerated concrete building block brick

The invention relates to the field of building materials, and provides an aerated concrete building block brick specific to the problem that the building block brick is difficult to cut and form. Theaerated concrete building block brick is prepared from the following ingredients in parts by mass: 45-60 parts of water, 25.5-34 parts of medium sand, 25.5-34 parts of gypsum, 21-28 parts of cement, 22.5-30 parts of lime, 2.1-2.8 parts of fish gelatin powder and 7.5-10 parts of hollow glass beads. By adding the fish gelatin powder, the fish gelatin powder has good affinity and water-retaining property, can form a skin membrane and is conducive to forming a protective film on the outer surface of the concrete building block brick, meanwhile, the thickness of concrete is increased, the concretebuilding block brick is conducive to forming a gelatinization shape in the recuperation process and takes on a jelly-like state in the cutting process, therefore, the elasticity and strength of the concrete building block is conducive to being improved, and the concrete building block is difficult to collapse in the cutting process and convenient to cut and form.

Owner:广州市宏利新型建材有限公司

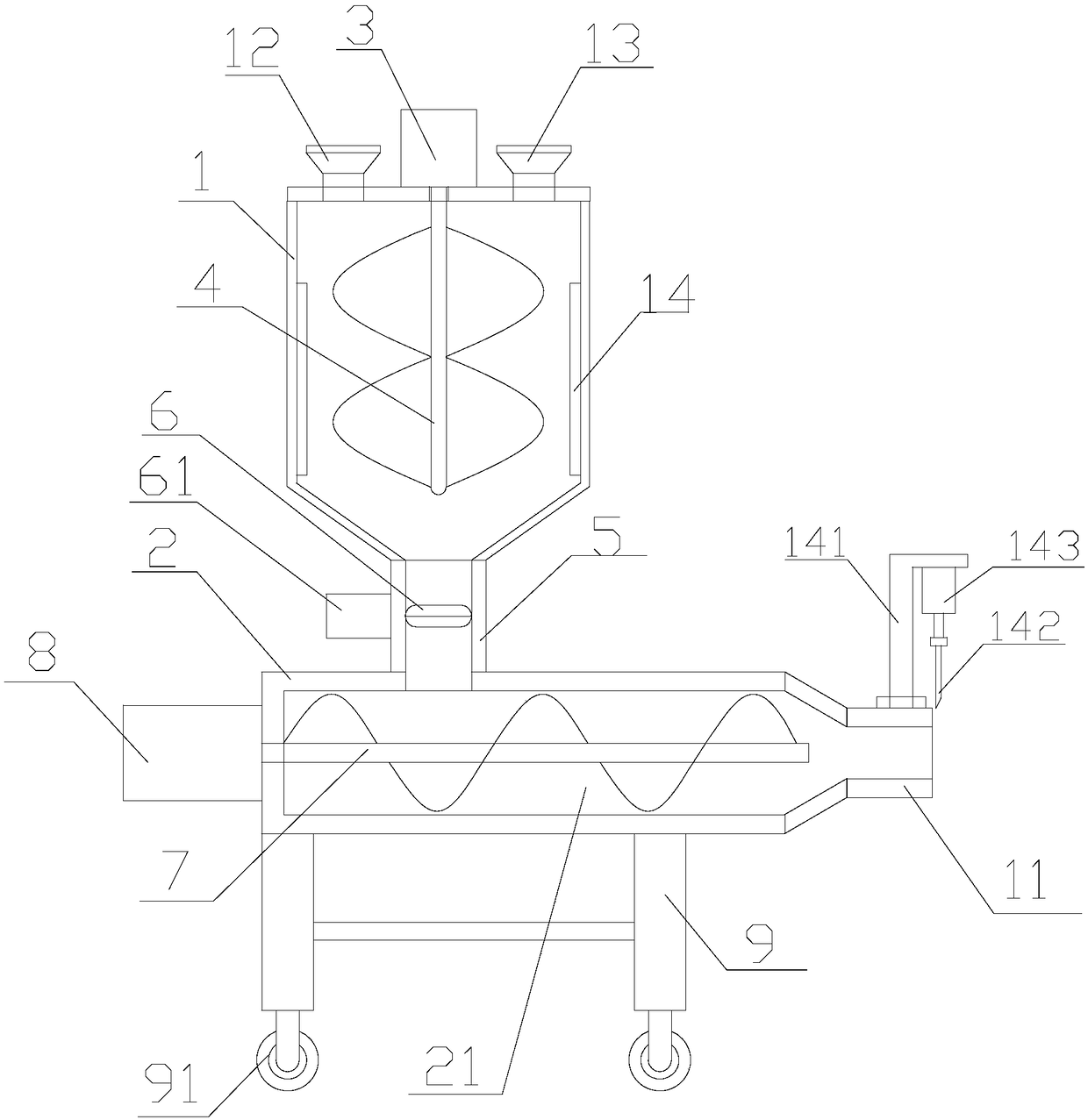

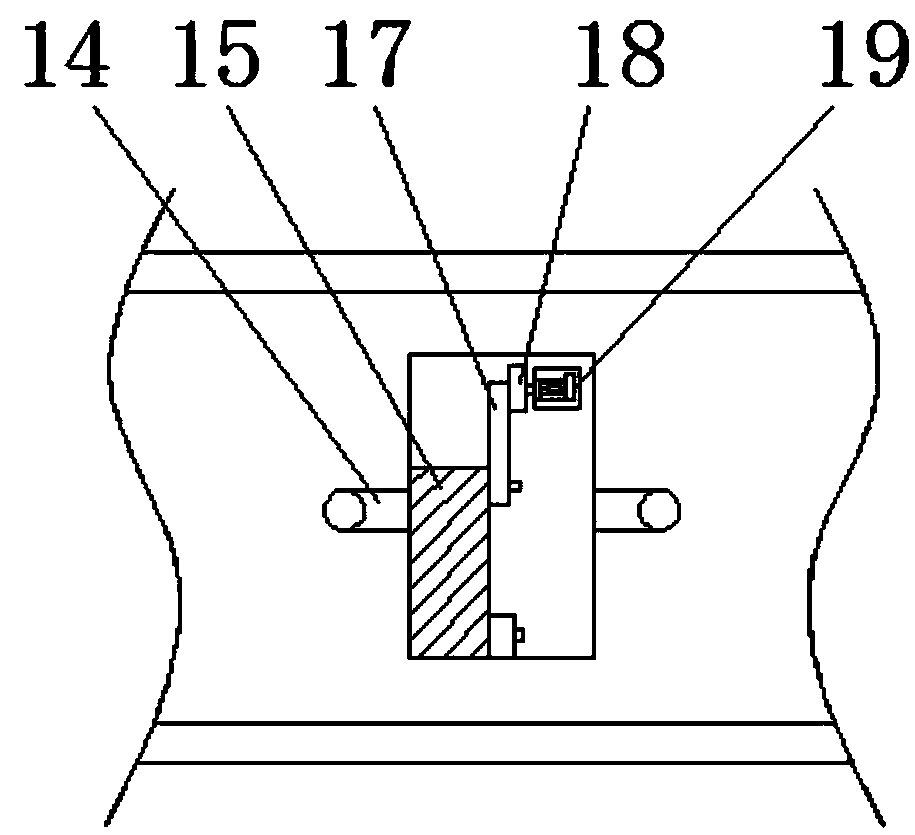

Stemming stirring and extruding device special for iron notch maintenance

The invention discloses a stemming stirring and extruding device special for iron notch maintenance. The stemming stirring and extruding device comprises a stirring tank, an extruded outer casing, a stirring motor, a stirring paddle, a connecting port, a butterfly valve, an extrusion screw, a conveying screw motor, a support frame, a tank cover and a discharge port; and the upper end of the stirring tank is provided with the tank cover, and the center of the upper end of the tank cover is provided with the stirring motor. Stemming stirring equipment is combined with a stemming extrusion molding device, the stemming stirring equipment can evenly stir stemming powder with a stemming solvent, the stemming extrusion molding device is arranged at the lower end of the stemming stirring equipment, stemming extrusion molding is directly carried out after stemming stirring is completed, transferring is not needed, time is saved, and efficiency is improved; the electric butterfly valve is arranged for separating the stemming stirring equipment from the stemming extrusion molding device, and control is facilitated; a cutting device is arranged, cutting and shaping are conveniently carried outduring stemming extrusion; and a powder feeding opening and a solvent feeding opening are formed in the drying tank for dry and wet separation, and the feeding openings are more tidy.

Owner:程智道

3D printing material with bacteriostatic function and preparation method thereof

The invention discloses a 3D printing material with the bacteriostatic function and a preparation method thereof. The 3D printing material is prepared from the following components in parts by weight: 120-140 parts of ABS (acrylonitrile butadiene styrene copolymers), 2-8 parts of light dispersing agent, 2-8 parts of initiator, 10-20 parts of cross-linking agent, 10-20 parts of coupling agent, 10-30 parts of clam shell powder, 2-8 parts of elemental sulfur, 1-4 parts of medical stone powder, 1-4 parts of walnut shell ultrafine powder, 1-6 parts of limonene, 4-20 parts of toosendainin, 2-8 parts of sweet stevia extract and 0.2-0.4 part of additive. The 3D printing material new variety is provided for users to selectively use as required and the application and development space of the 3D printing material with ABS as the main raw material is greatly expanded from the aspect of the 3D printing material, so the significance is outstanding.

Owner:JIANGSU HAOYU ELECTRONICS TECH

High-plasticity insect-trapping 3D printing material and preparation method thereof

InactiveCN105907022AEnhanced network structureImprove toughnessAdditive manufacturing apparatusSulfurLimonene

The invention discloses a high-plasticity insect-trapping 3D printing material and a preparation method thereof. The 3D printing material is prepared from the following components in parts by weight: 120-140 parts of ABS (acrylonitrile-butadiene-styrene), 2-8 parts of photodiffusion agent, 2-8 parts of initiator, 10-20 parts of crosslinking agent, 10-20 parts of coupling agent, 10-30 parts of clam shell powder, 2-8 parts of simple substance sulfur, 1-4 parts of nutshell ultramicropowder, 1-6 parts of limonene, 4-20 parts of antimicrobial agent, 2-8 parts of stevia rebaudiana extract, 2-8 parts of noctilucent powder and 0.2-0.4 part of aid. The invention provides a 3D printing material new species for the users to select and use according to needs, thereby greatly widening the application and development space of the 3D printing material mainly prepared from ABS in the aspect of 3D printing materials, and having obvious meanings.

Owner:JIANGSU HAOYU ELECTRONICS TECH

3D printing material with function of trapping and killing insects and preparation method thereof

InactiveCN105778395AEnhanced network structureImprove toughnessAdditive manufacturing apparatusSulfurLimonene

The invention discloses a 3D printing material with the function of trapping and killing insects and a preparation method thereof. The 3D printing material is prepared from the following components in parts by weight: 120-140 parts of ABS (acrylonitrile butadiene styrene copolymers), 2-8 parts of light dispersing agent, 2-8 parts of initiator, 10-20 parts of cross-linking agent, 10-20 parts of coupling agent, 10-30 parts of clam shell powder, 2-8 parts of elemental sulfur, 1-4 parts of medical stone powder, 1-4 parts of walnut shell ultrafine powder, 1-6 parts of limonene, 4-20 parts of toosendainin, 2-8 parts of sweet stevia extract, 2-8 parts of noctilucent powder and 0.2-0.4 part of additive. The 3D printing material new variety is provided for users to selectively use as required and the application and development space of the 3D printing material with ABS as the main raw material is greatly expanded from the aspect of the 3D printing material, so the significance is outstanding.

Owner:JIANGSU HAOYU ELECTRONICS TECH

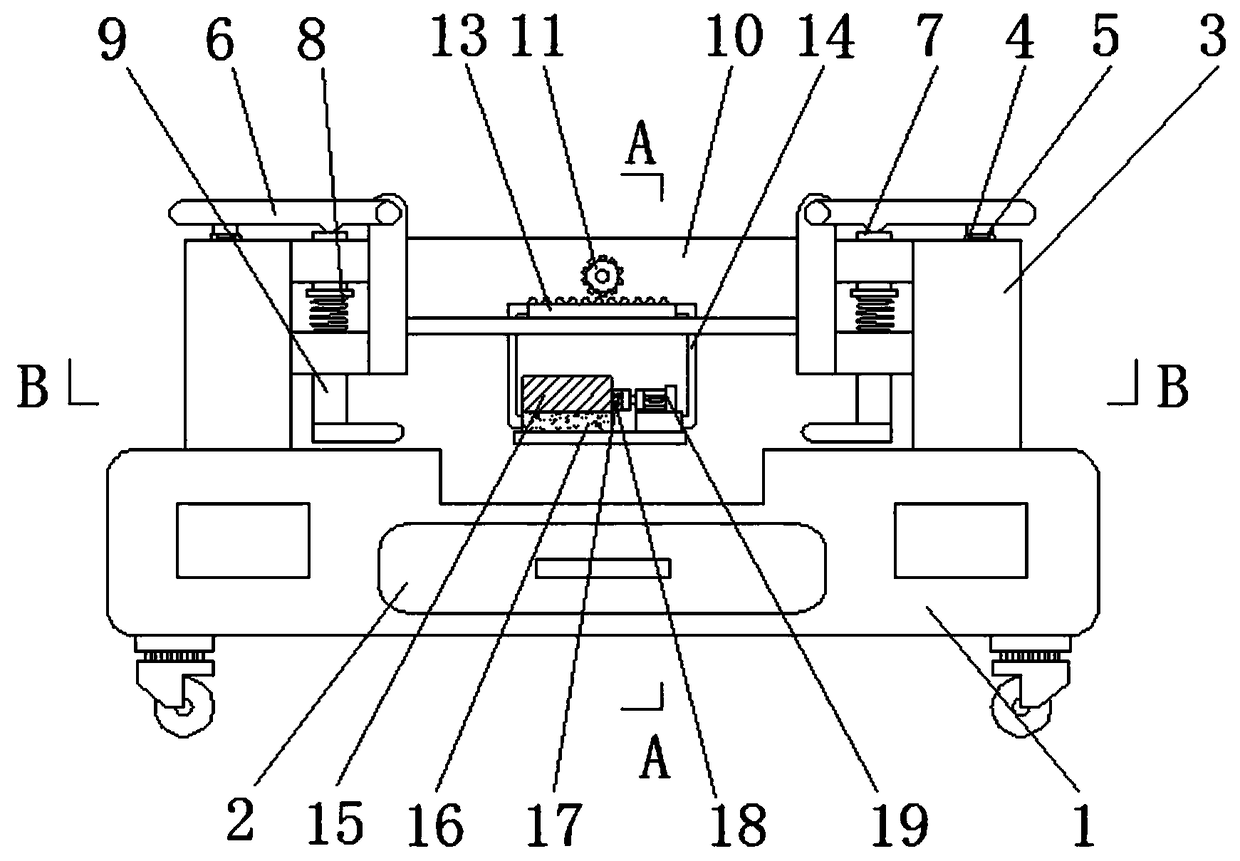

Paper diaper cutting device making paper diaper undergo shaping cutting conveniently

The invention discloses a paper diaper cutting device making a paper diaper undergo shaping cutting conveniently. The paper diaper cutting device comprises a base, a drawer is arranged in the middle of the base, a spring is connected to the lower end of a connecting rod, the lower end of the spring is connected with a clamping block, a transverse plate is arranged on the inner side of the fixing rod, the middle of the transverse plate is provided with a gear, a first driving motor is installed on the rear side of the transverse plate, a transverse block is connected below the gear, the left end and the right end of the transverse block are provided with bearing rods, the inner sides of the bearing rods are provided with a first cutting blade, a second cutting blade is arranged below the first cutting blade, the right side of the second cutting blade is connected with a first limiting rod, the right side of the first limiting rod is connected with a second limiting rod, and a second driving motor is arranged on the right side of the second limiting rod. According to the paper diaper cutting device, the paper diaper is convenient to fix, so that the working efficiency is improved, and the paper diaper can conveniently undergo shaping cutting.

Owner:JIANGXI MEIMAN LIFE ARTICLES CO LTD

Preparation method of moisturizing instant rice

ActiveCN103519056BTraits that are easy to controlImprove adaptabilityFood thermal treatmentMulti-step food processesBroken riceWater content

The invention discloses a preparation method of moisturizing instant rice. By taking broken rice as a raw material, the moisturizing instant rice is prepared by the following steps: pre-cooking; drying; crushing; carrying out twin-screw extrusion; cutting and moulding; packaging; sealing; and sterilizing. In the pre-cooking step, the degree of gelatinization is controlled at 40-60%. In the drying step, the water content is controlled at 20-25%. According to the invention, the moisturizing instant rice is processed and prepared by adopting pre-cooking step combined with twin-screw extrusion, so that the moisturizing instant rice prepared is full in particle, glittering and translucent in color and luster, appropriate in hardness and chewiness and durable in storage, and the quality of the moisturizing instant rice is close to that of natural rice.

Owner:JIANGNAN UNIV

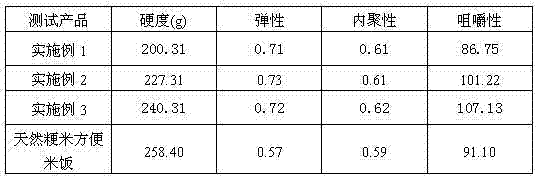

An indoor carbonized cork vertical plant cultivation device

InactiveCN103931440BImprove survival rateEasy to viewWatering devicesPisciculture and aquariaCarbonizationLiquid storage tank

The invention discloses an indoor carbonization cork-wood vertical device for cultivating plants, and belongs to the field of plant cultivating. The indoor carbonization cork-wood vertical device comprises a fixing box, a liquid storage tank, a water pump, a water supplying pipe, a water drainage pipe, a carbonation cork-wood cultivating frame and a water supplying tank, the liquid storage tank is located on the lower portion of the fixing box, the water supplying tank is located on the upper portion of the fixing box, the carbonation cork-wood cultivating frame is installed in a groove of the fixing box and located between the liquid storage tank and the water supplying tank, cultivating grooves are formed in the carbonation cork-wood cultivating frame, the water pump is arranged inside the liquid storage tank and communicated with the water supplying tank through the water supplying pipe, the water supplying tank is communicated with the liquid storage tank through the water drainage pipe, and a water sucking and guiding device for providing water for the plants is arranged between the carbonation cork-wood cultivating frame and the water supplying tank. According to the indoor carbonization cork-wood vertical device, the plants are cultivated through the excellent characteristics of carbonization cork wood, water adjustment is facilitated, and the survival rate and the ornamental value of the plants are improved; meanwhile, even water supplying is guaranteed, water supplying noise is lowered, the structure is simple, and cost is low; in addition, plant bonsais can be changed at will, and maintenance is convenient to achieve.

Owner:罗荣华

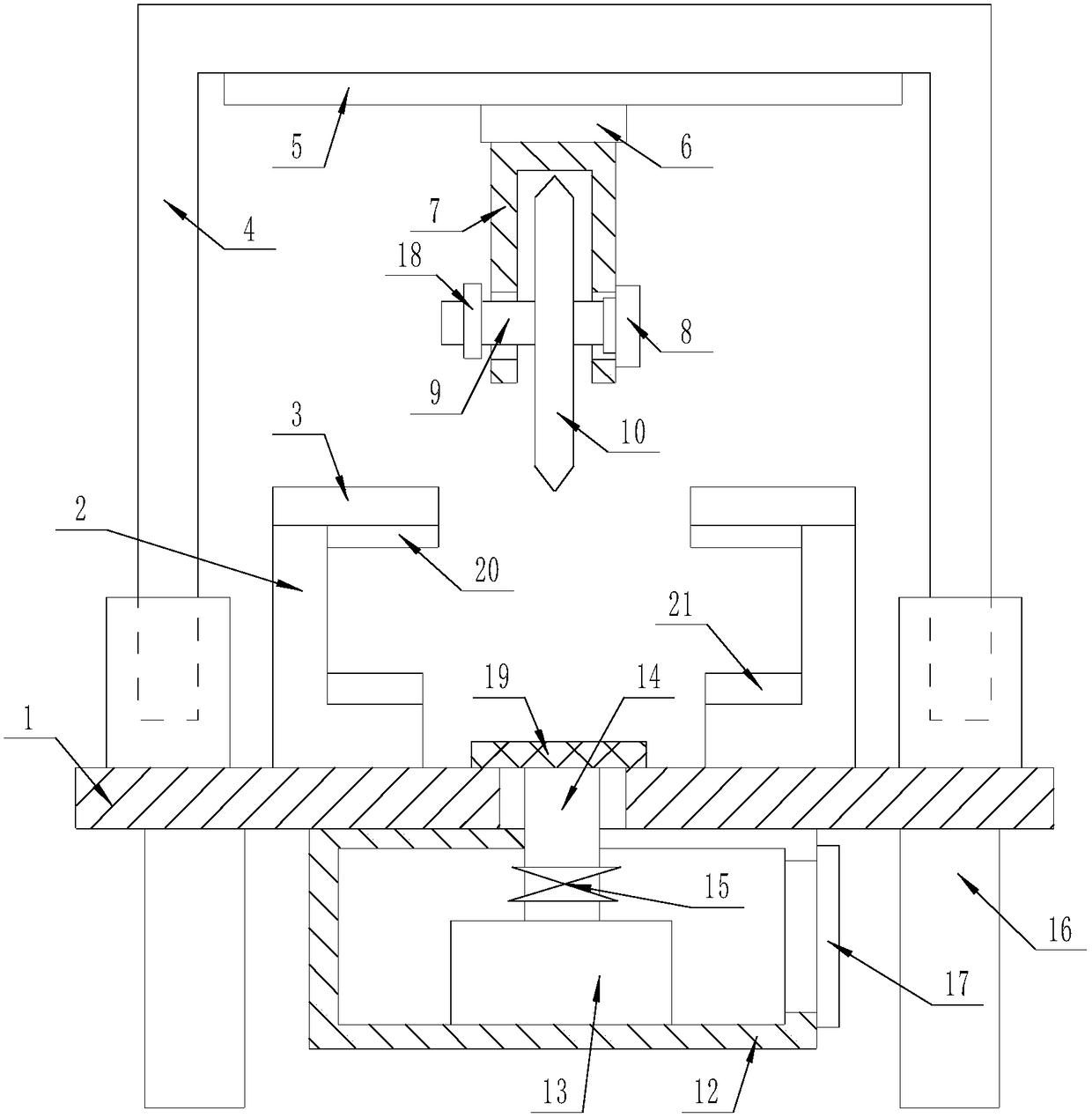

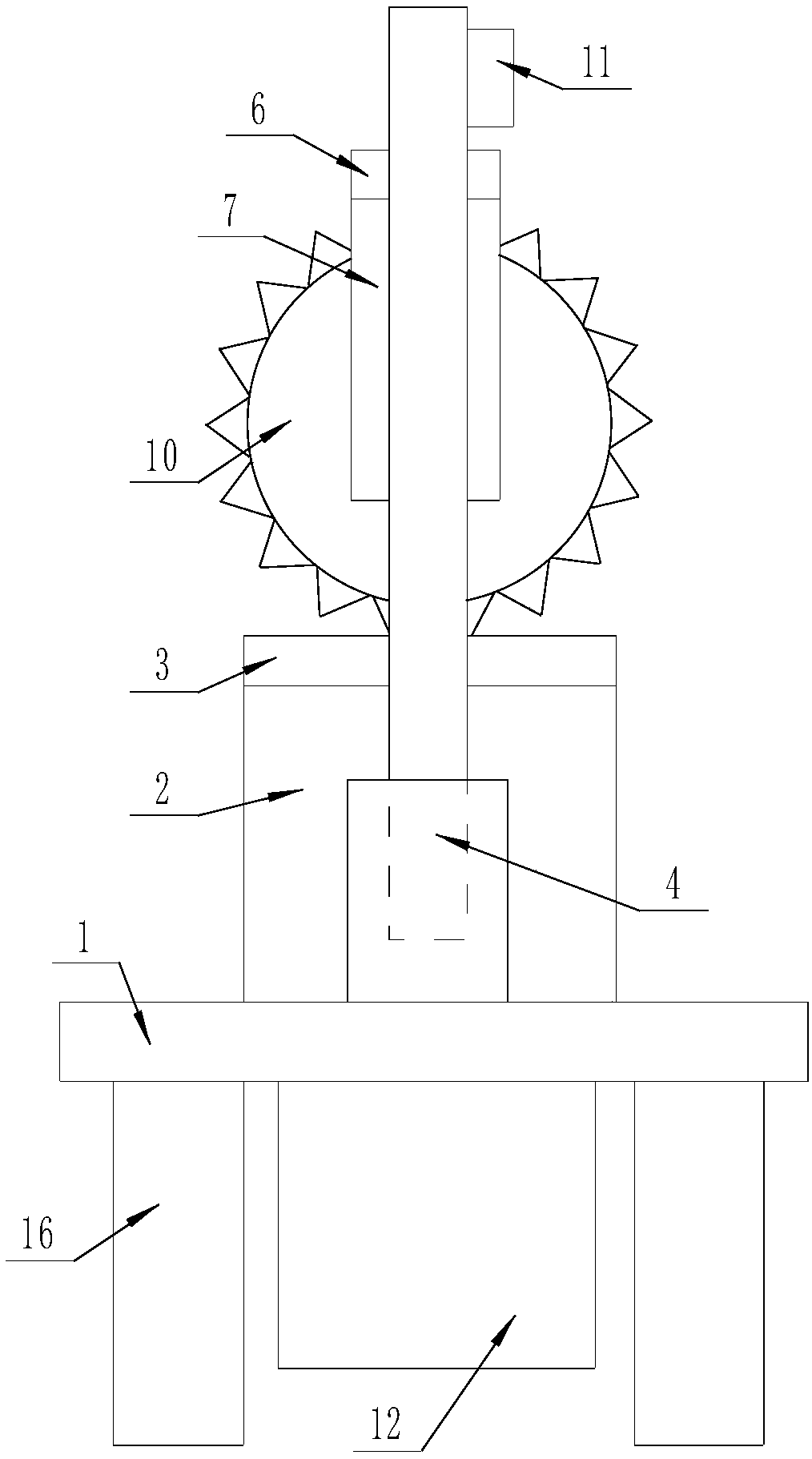

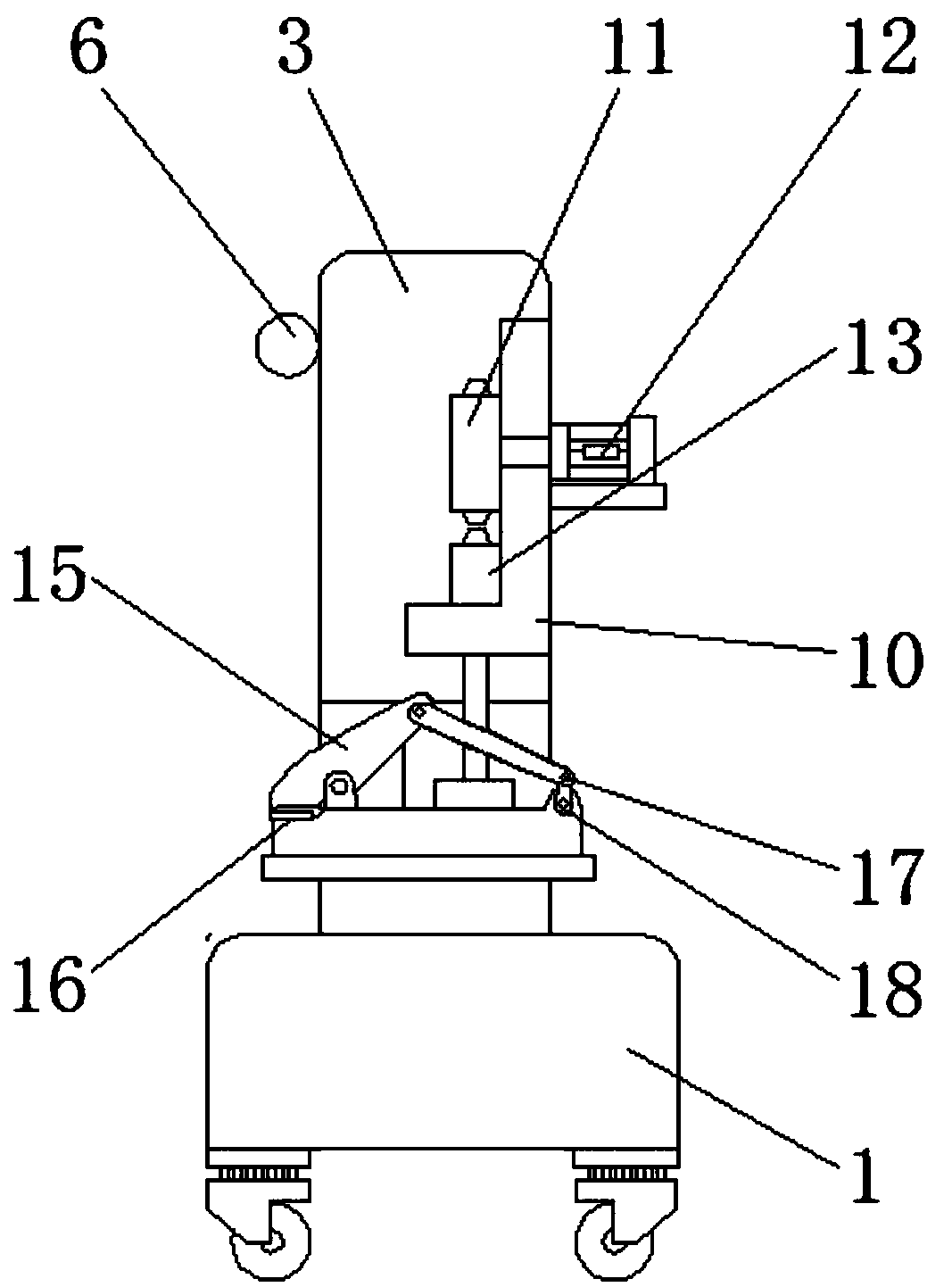

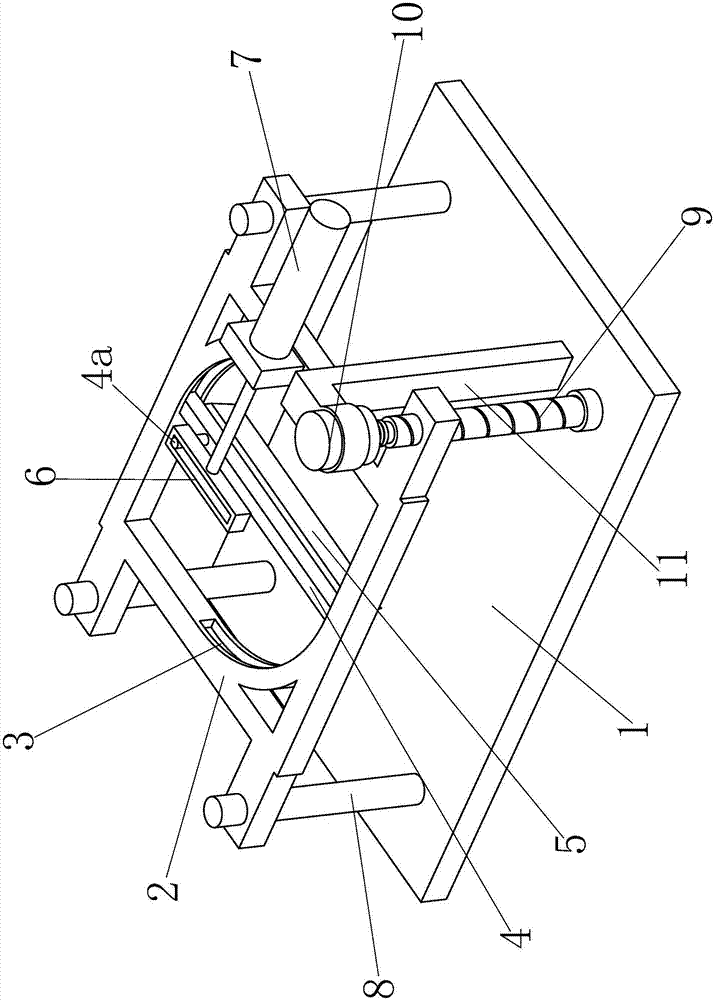

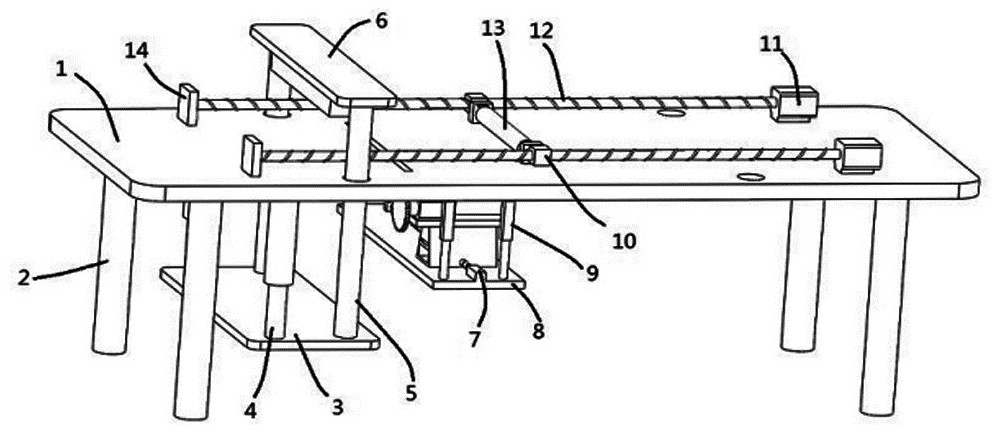

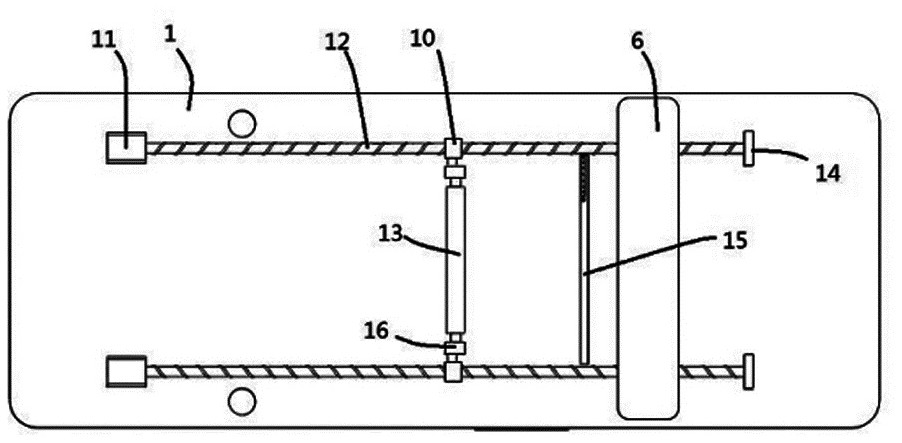

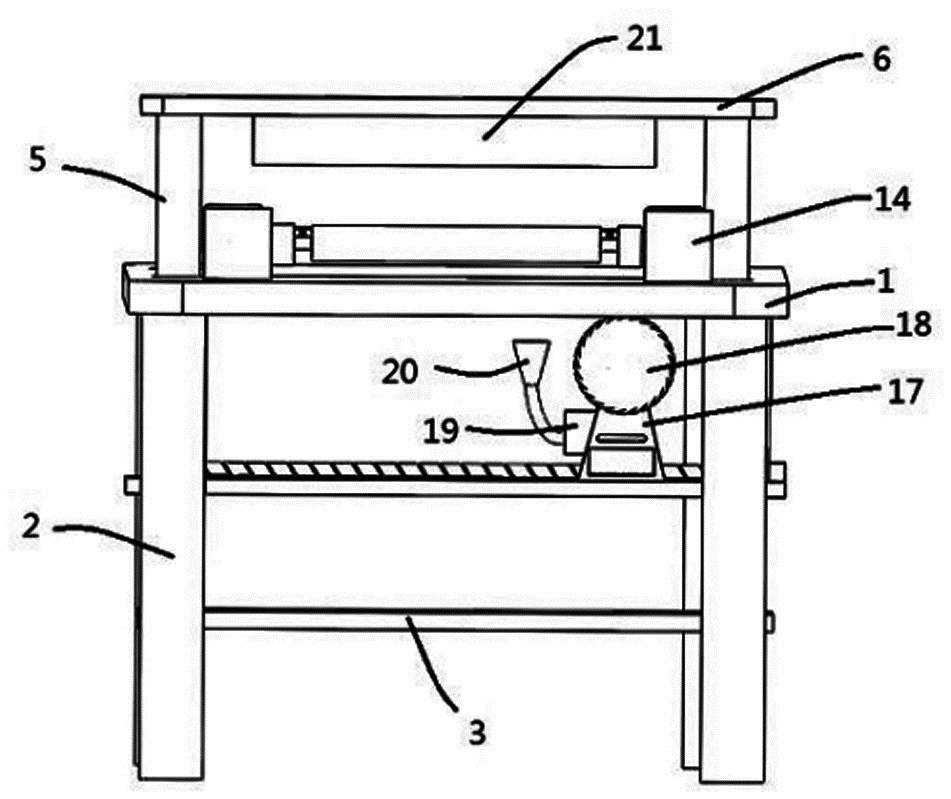

Double cutting device for aerated block

ActiveCN107234717AHigh degree of automationEasy to cut and shapeCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to a double cutting device for an aerated block. The double cutting device for the aerated block comprises a bottom plate. A screw rod lifting device is arranged on the bottom plate, and a base frame is installed on the screw rod lifting device; two arc-shaped sliding grooves are formed in the middle part of the base frame, a cross rod is slidably installed in the two sliding grooves together, and a cutting knife is fixedly installed at the lower end of the cross rod. A protruding block is arranged on the upper end of the cross rod, the protruding block is installed on a side frame which is arranged above the cross rod, and a cylinder, fixedly installed on the base frame, is connected with the side frame. The double cutting device for the aerated block is high in automatic degree, the cutting knife can be driven by transmitting of the screw rod nut to rise and fall, an aerated block green body is cut automatically, simultaneously, angle position of the cutting knife can be changed automatically, the effect of convenient cutting and shaping of the aerated block green body is achieved.

Owner:芜湖富创新型建材有限公司

Advertising board processing equipment

ActiveCN112044983AGuaranteed flatnessNo deformationSpraying apparatusOther manufacturing equipments/toolsEngineeringWorkbench

The invention discloses advertising board processing equipment. A forming flattening mechanism of the advertising board processing equipment comprises a flattening workbench base, a lower powerful magnet, a flattening workbench, a first flattening electromagnetic mechanism, a second flattening electromagnetic mechanism, a driving mechanism and a flattening controller, and flattening treatment on an advertising board blank is achieved through attraction force of magnetic force. Meanwhile, due to movement under magnetic attraction force, the flattening capacity of a flattened board blank can beguaranteed, the flattened advertising board blank cannot deform, and the flattened shape can be kept. The first flattening electromagnetic mechanism and the second flattening electromagnetic mechanismare driven by the driving mechanism to move oppositely on the flattening workbench, so that the advertising board blank between the flattening workbench and the first flattening electromagnetic mechanism and between the flattening workbench and the second flattening electromagnetic mechanism can be flattened and formed well, and the treatment efficiency is high and reliable.

Owner:WUHAN TECHN COLLEGE OF COMM

High-plasticity corrosion-resistant temperature-resistant pre-hardening plastic die steel and preparation method thereof

InactiveCN105177438AImprove mechanical properties and casting cutting performanceExcellent strength and wear resistance, high temperature oxidation and corrosion resistanceAlloy elementCorrosion resistant

The invention discloses a high-plasticity corrosion-resistant temperature-resistant pre-hardening plastic die steel, and according to the die steel, the ratio of the elements such as Mn, Mo, Cr and Ti are properly improved based on the element ratio of a conventional pre-hardening plastic die steel, meanwhile, the usage of other alloy elements is controlled, so that the mechanical properties and pouring cutting properties of the alloy are further improved on the basis of the mechanical properties and processability of the conventional plastic die steel, and the die steel has excellent strength, wear resistance, high temperature resistance and oxidation resistance and corrosion resistance, is better in plasticity, and easy to cut and form, can be used for pouring plastic parts of various types, moreover, a tissue structure of the die steel is further improved by an added rare earth oxide-cladded nano tungsten carbide composite modifier, so that a reinforcing and toughening effect is obvious, and the wettability with alloy fluid is better, and a metamorphism effect is uniform and stable; a preparation method of the die steel is simple and efficient, short in manufacturing period and capable of greatly improving the quality of plastic products and has high production and application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Stone processing and treatment method for indoor decoration material of building

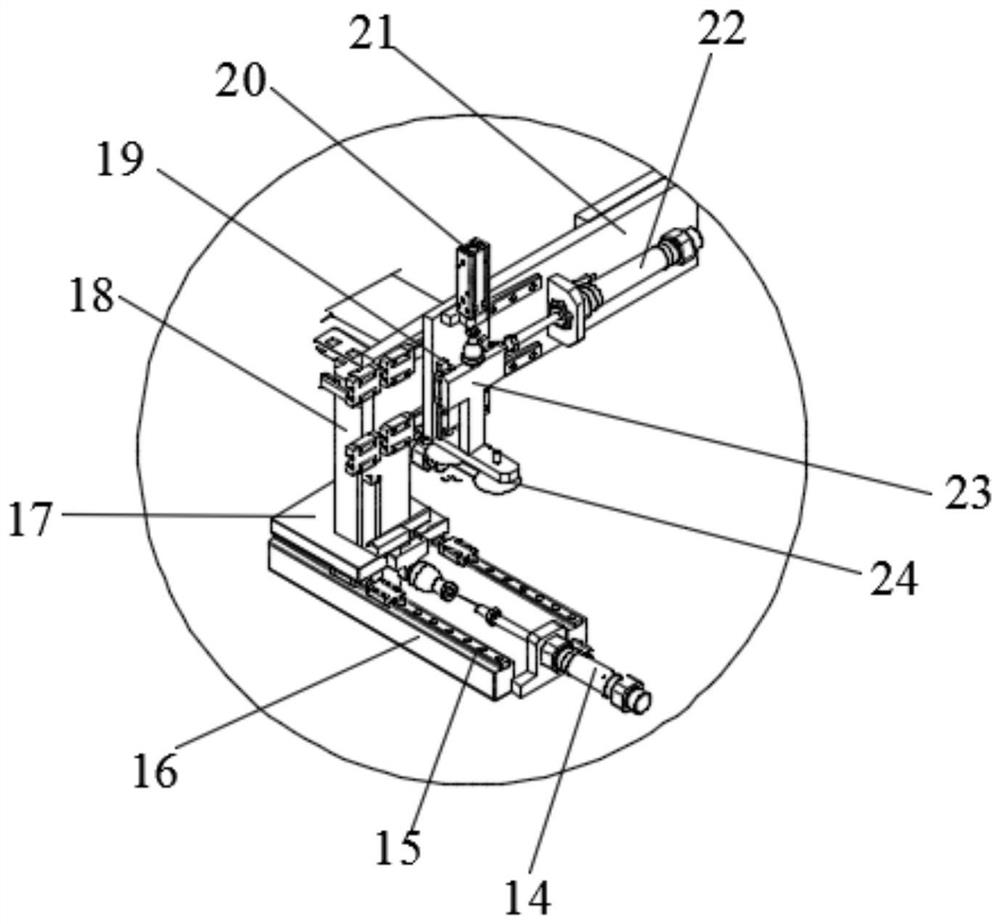

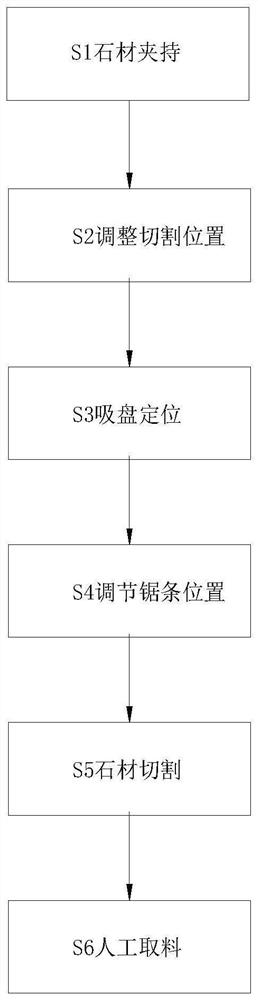

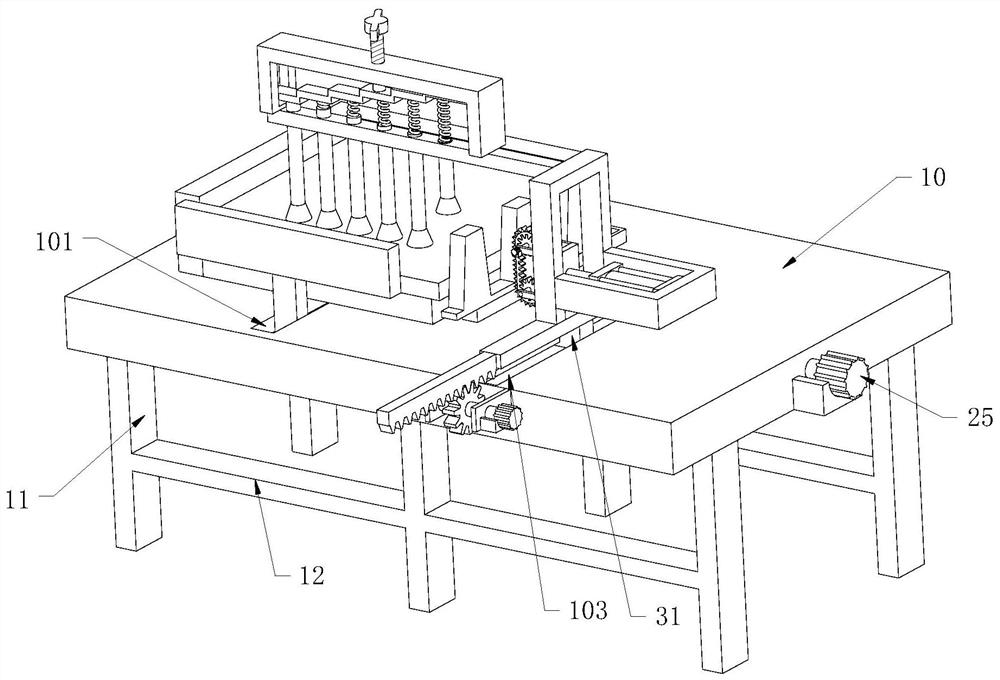

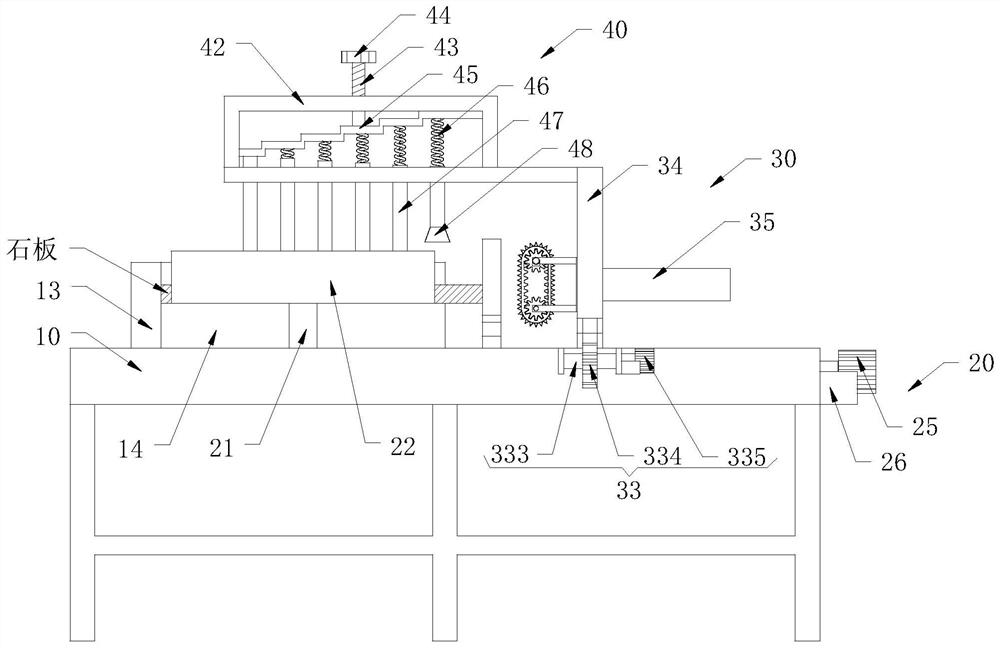

InactiveCN112454679ANot easy to shiftAvoid offsetCovering/liningsWorking accessoriesLinear motionFlagstone

The invention relates to a stone processing and treatment method for an indoor decoration material of a building, and using stone processing and manufacturing equipment. The equipment comprises a workbench and a fixing device arranged at the top of the workbench, wherein a cutting device is arranged at the right side of a bottom plate, and a locating device is arranged at the left side of a firstn-shaped frame. According to the invention, an electric cross-shaped sliding block can move forwards in the width direction of a second cross-shaped groove through cooperation of designed locating baffle, fixing plate and second cross-shaped groove, the electric cross-shaped sliding block drives the locating baffle to move synchronously, and two groups of adjacent trapezoidal plates in the locating baffle are moved to the front end and the rear end of a drawn horizontal straight line; therefore, reciprocating linear motion of the locating baffle can be realized, the corners of a rectangular stone plate to be machined can be conveniently fixed and adjusted at the same time, the cutting machining position is not blocked, time and labor are saved, and the rectangular stone plate to be machined can be cut at any position.

Owner:南京乐飞电科技有限公司

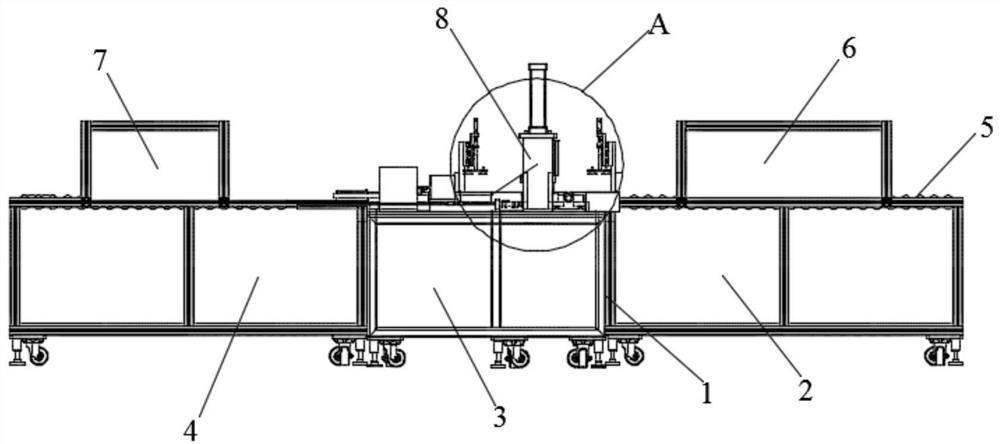

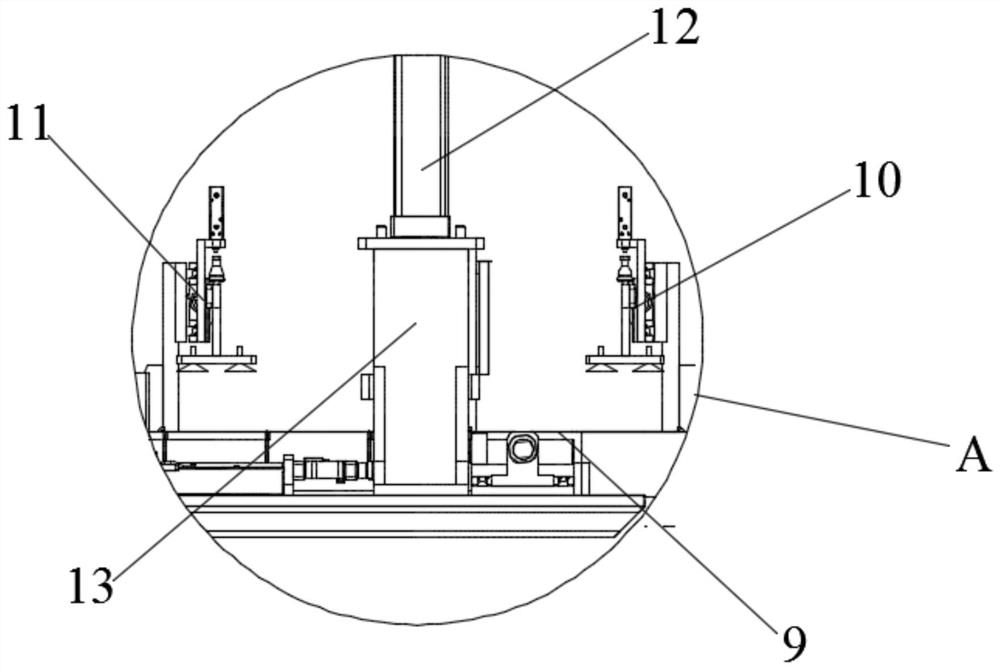

Automatic cutting forming machine for hard carbon felt

ActiveCN110670340AEasy to cut and shapeImprove cutting accuracySevering textilesMolding machineElectric machinery

The invention discloses an automatic cutting forming machine for a hard carbon felt. The automatic cutting forming machine comprises a top plate, a cutting mechanism, a pressing mechanism and a spreading mechanism, supporting legs are arranged at corners of the bottom surface of the top plate, a cutting hole is formed in one side of the top plate along the width direction of the top plate, the cutting mechanism is arranged below the top plate, a cutting wheel in the cutting mechanism moves in the cutting hole to cut the carbon felt, the pressing mechanism comprises a pressing plate and a driving unit, the pressing plate is parallelly arranged on the top plate, the driving unit drives the pressing plate to vertically move, the pressing plate is arranged along the width direction of the topplate, the spreading mechanism two lead screws, a first motor, mounting blocks and a spreading unit, the lead screws are parallelly arranged along the length direction of the top plate, the first motor drives the lead screws to rotate, the mounting blocks are spirally connected on the lead screws in a sleeving manner, the spreading unit is arranged between the two mounting blocks, the lead screwsare parallel to the top plate, the first motor is fixed onto the top surface of the top plate, and the mounting blocks are slidably connected with the top plate. According to the automatic cutting forming machine, the carbon felt is conveniently and closely pressed, and the automatic cutting forming machine is high in cutting accuracy and simple and convenient to operate.

Owner:厦门靠谱知识产权服务有限公司

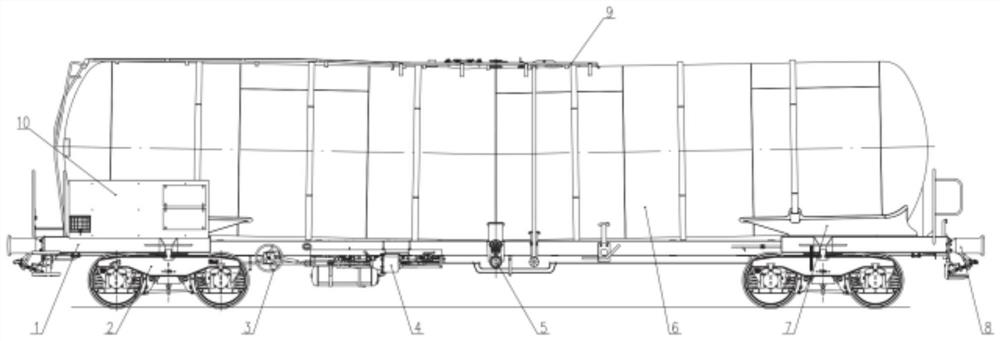

Railway tank car body and railway tank car

ActiveCN114104017AEasy to cut and shapeHigh manufacturability and yieldRailway transportTank wagonsAutomotive engineeringMarine engineering

The invention discloses a railway tank car body and a railway tank car, and belongs to the technical field of railway vehicle equipment.The railway tank car body comprises an underframe assembly, a tank body assembly and a loading and unloading system, the tank body assembly is installed on the underframe assembly through a tank body support assembly, and the loading and unloading system is installed on the tank body assembly; the tank assembly comprises a first cylinder and a second cylinder, the ends of the first cylinder and the second cylinder are in butt joint, and a set included angle is formed between the axes of the first cylinder and the second cylinder. The loading and unloading system comprises a bottom valve and a bottom valve control mechanism connected with the bottom valve, and an automatic ventilation valve is installed at the top of the first barrel or the second barrel and connected with the bottom valve through a linkage mechanism. The requirement for light weight of a vehicle body can be met, various light oil medium loading and unloading modes can be achieved, it is guaranteed that medium steam does not escape or leak and can be recycled, and the safety of a loading and unloading system under unforeseen circumstances is met.

Owner:CRRC SHANDONG CO LTD

Plasticization penetration processing technique of Jordan almond

Owner:东莞市绰士食品有限公司

3D printing material with function of multiply trapping and killing insects and preparation method thereof

InactiveCN105778398AEnhanced network structureImprove toughnessAdditive manufacturing apparatusSulfurLimonene

The invention discloses a 3D printing material with the function of multiply trapping and killing insects and a preparation method thereof. The 3D printing material is prepared from the following components in parts by weight: 120-140 parts of ABS (acrylonitrile butadiene styrene copolymers), 2-8 parts of light dispersing agent, 2-8 parts of initiator, 10-20 parts of cross-linking agent, 10-20 parts of coupling agent, 10-30 parts of clam shell powder, 2-8 parts of elemental sulfur, 1-4 parts of medical stone powder, 1-4 parts of walnut shell ultrafine powder, 1-6 parts of limonene, 4-20 parts of toosendainin, 2-8 parts of sweet stevia extract, 2-8 parts of photochromic toner and 0.2-0.4 part of additive. The 3D printing material new variety is provided for users to selectively use as required and the application and development space of the 3D printing material with ABS as the main raw material is greatly expanded from the aspect of the 3D printing material, so the significance is outstanding.

Owner:JIANGSU HAOYU ELECTRONICS TECH

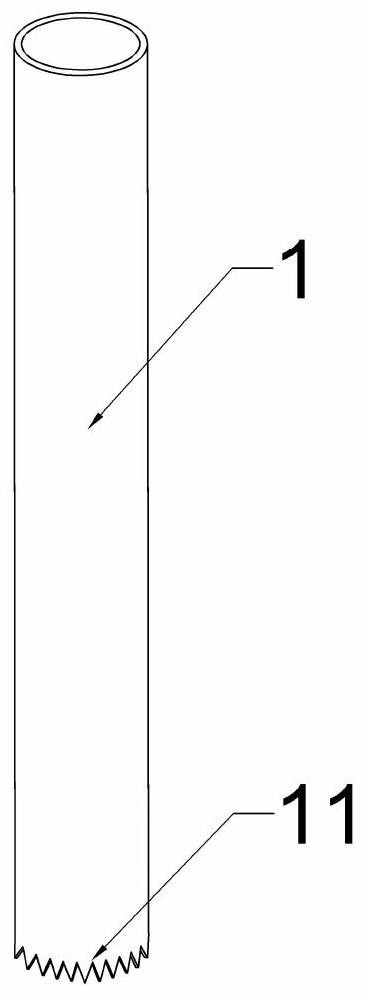

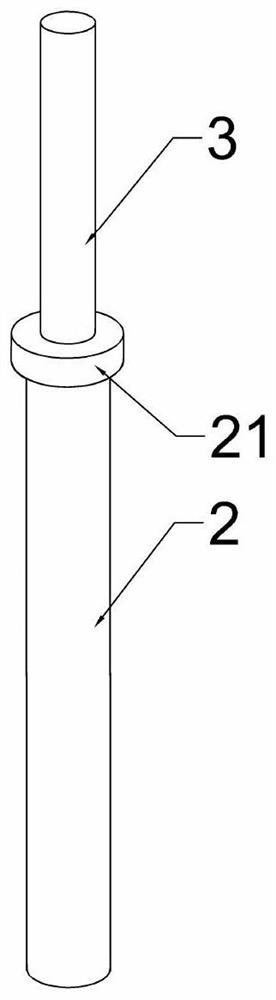

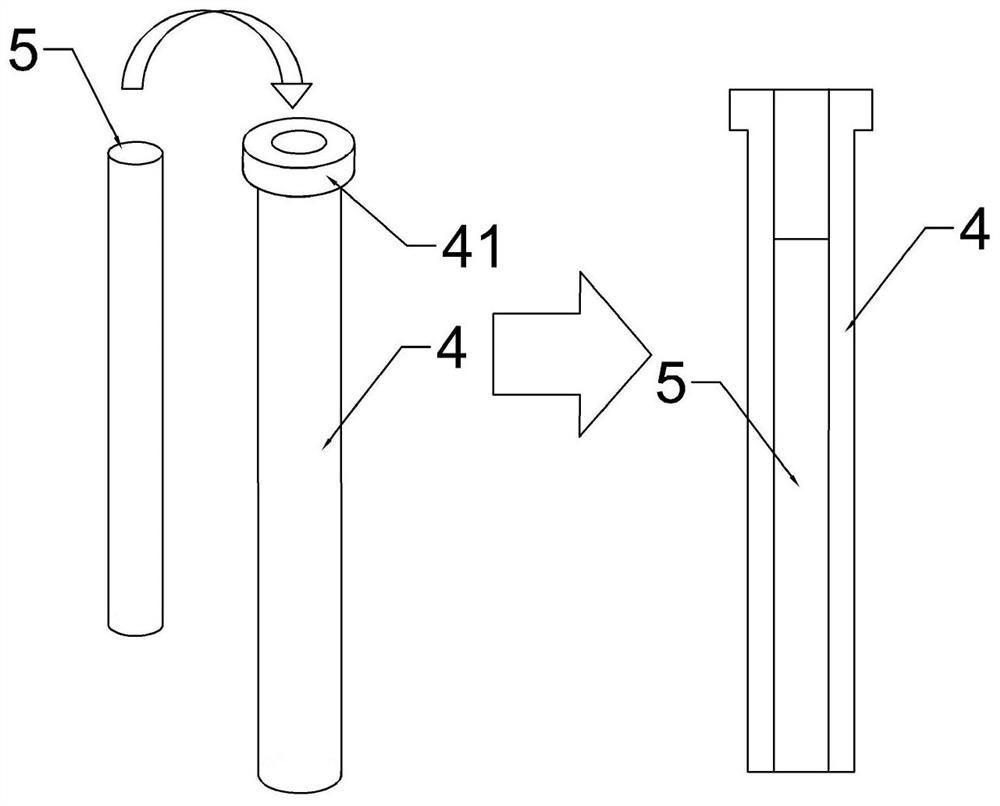

Device, kit and method for repairing and fixing articular cartilage

PendingCN112842451AGood biological binding interfaceEasy to cut and shapeDiagnosticsSurgeryArticular surfacesArticular surface

The invention provides a device, a kit and a method for repairing and fixing articular cartilage. The device comprises a costal cartilage rod, an outer sleeve, a drilling part and an auxiliary implantation part; the drilling part comprises a drilling sleeve and a drill bit matched with the inner diameter of the drilling sleeve; the auxiliary implanting part comprises a cartilage rod sleeve and an auxiliary propelling part, the cartilago costal rod is of a rod-shaped structure which is processed into the cartilago costal and has the diameter of 3-8mm and is smaller than the inner diameter of the cartilago costal rod sleeve, and the cartilago costal rod is derived from autologous, allogeneic or heterogeneic cartilago costal. According to the device, costal cartilage is processed into a cartilage rod, the cartilage rod, the articular cartilage to be fixed and a cancellous bone of a bone bed can form a good biological bonding interface, and the costal cartilage which can be adopted is sufficient, is easy to cut and form and can be produced in a large scale; the surface of the cartilage rod can be shaped with an articular surface through cutting, and has biomechanical characteristics similar to articular cartilage. The method provided by the invention is strong in operability, simple and rapid, and provides a new strategy for the repair treatment of related femoral cartilage injury.

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

Automated Cutting and Forming Machine for Rigid Carbon Felt

ActiveCN110670340BEasy to cut and shapeImprove cutting accuracySevering textilesMolding machineElectric machinery

The invention discloses an automatic cutting and forming machine for hard carbon felt, which comprises a top plate, a cutting mechanism, a pressing mechanism, and a leveling mechanism. The corners of the bottom surface of the top plate are all top plates, and one side of the top plate is provided with cutting along its width direction. hole, the cutting mechanism is arranged under the top plate, and the cutting wheel contained in the cutting mechanism moves and cuts off the carbon felt in the cutting hole, and the pressing mechanism includes a pressing plate arranged in parallel above the top plate, and a device for driving the pressing plate to move longitudinally. Drive unit, and the pressure plate is set along the width direction of the top plate, the flattening mechanism includes two screw rods parallel to each other and set in the length direction of the top plate, the first motor to drive the screw rods to rotate, and the two screw rods are respectively helically sleeved The installation block and the leveling unit arranged between the two installation blocks, the screw rod is arranged parallel to the top plate, the first motor is fixed on the top surface of the top plate, and the top plate of the installation block is slidably connected. The invention conveniently compresses the carbon felt, has high cutting precision, and is simple and convenient to operate.

Owner:厦门靠谱知识产权服务有限公司

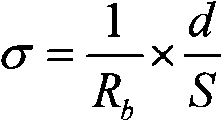

Leather strip cutter

InactiveCN107267692ASimple structureLow costSkins/hides/leather/fur manufacturing hand toolsLeather clicking/perforating/clickingFixed frameVertical edge

The invention discloses a leather strip cutter. The leather strip cutter comprises a base, a cushion block, a check block, a plurality of spaced wheels, a mounting shaft, a fixed frame and cutting blades, wherein the fixed frame is in an L shape, a fixed frame transverse plate is arranged on the transverse edge of the L-shaped fixed frame, a transverse sliding groove is formed in the fixed frame transverse plate and corresponds to a sliding chute in the base in position, and an adjustment bolt is arranged in the sliding groove; the spaced wheels are fixed to one end of the mounting shaft, one end of each cutting blade is clamped between the base and the cushion block, and the other end of each cutting blade is clamped between the two corresponding adjacent spaced wheels; and the other end of the mounting shaft transversely penetrates through the vertical edge of the L-shaped fixed frame, and the end, stretching out of the L-shaped fixed frame, of the mounting shaft is sleeved with a tail nut. The leather strip cutter is simple in structure and low in overall cost and can be widely used by broad masses of leatherware handwork amateurs; and the leather strip cutter can meet the requirement of the leatherware handwork amateurs for rapid cutting of leather strips with required widths, the cutting formability is good, and the leather strip cutter is extremely convenient to use.

Owner:成都绘古科技有限公司

A kind of automatic processing method of almond flakes

ActiveCN103535796BFully soakedEasy to peelMulti-step food processesFood shapingMicrowaveFluidized bed

The invention relates to a method for processing nuts and in particular relates to a method for automatically processing almond slices. The method comprises the following steps: A. cleaning almonds to be processed by a nut cleaning device; B. carrying out rolling stewing on the cleaned almonds by a precooker; C. peeling the stewed almonds by a peeling machine; D. carrying out color sorting on the peeled almond pulps by a color sorter; E. carrying out microwave baking on the almond pulps by a microwave baker; F. cutting the almond pulps into almond slices by a slicing machine; G. carrying out vibratory screening on the cut almond slices by a vibrating screen; and H. drying and dehydrating the almond slices by a fluidized bed through high-temperature vapor being 160-190 DEG C. According to the method for automatically processing the almond slices, the efficiency is high, the cost is low, the qualification rate of the produced almond slices is high, and raw materials are saved.

Owner:东莞市绰士食品有限公司

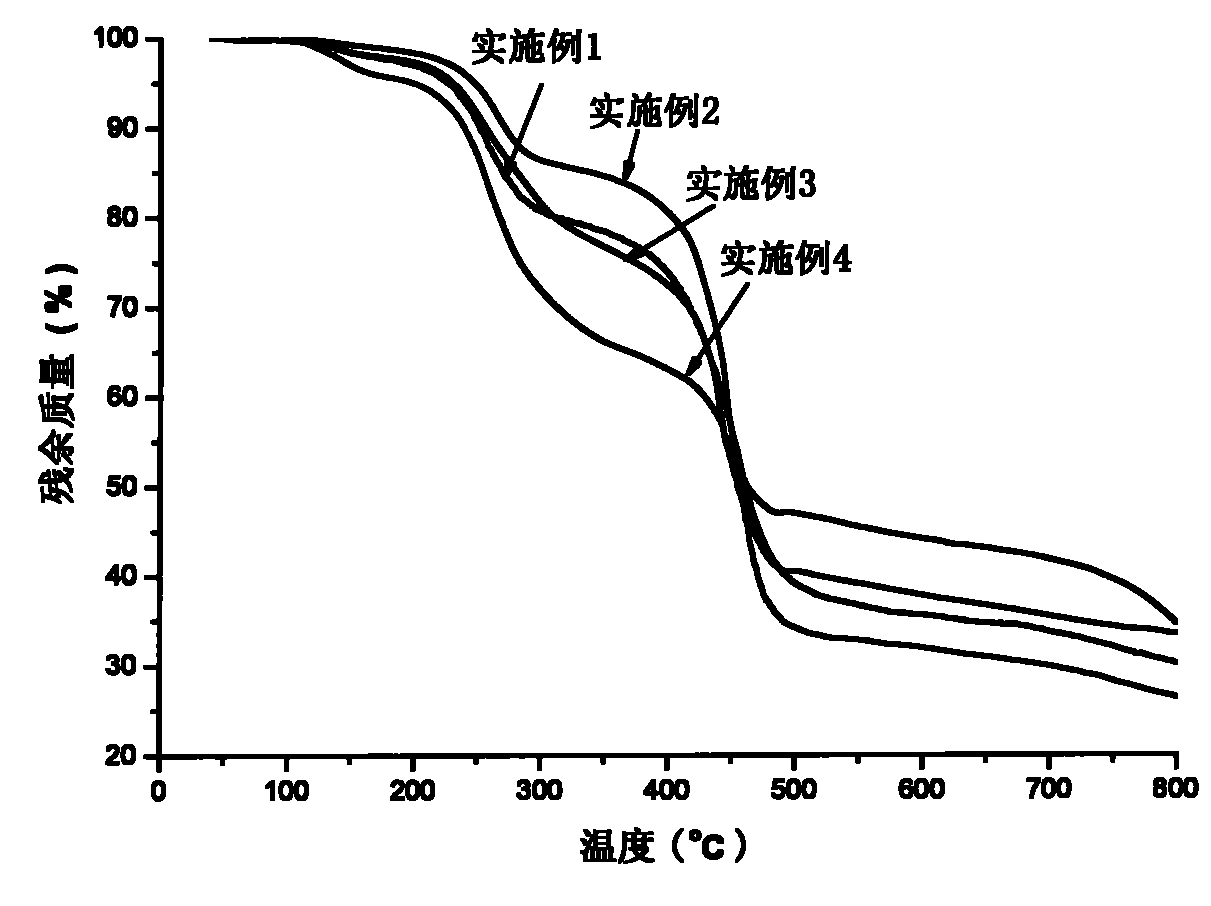

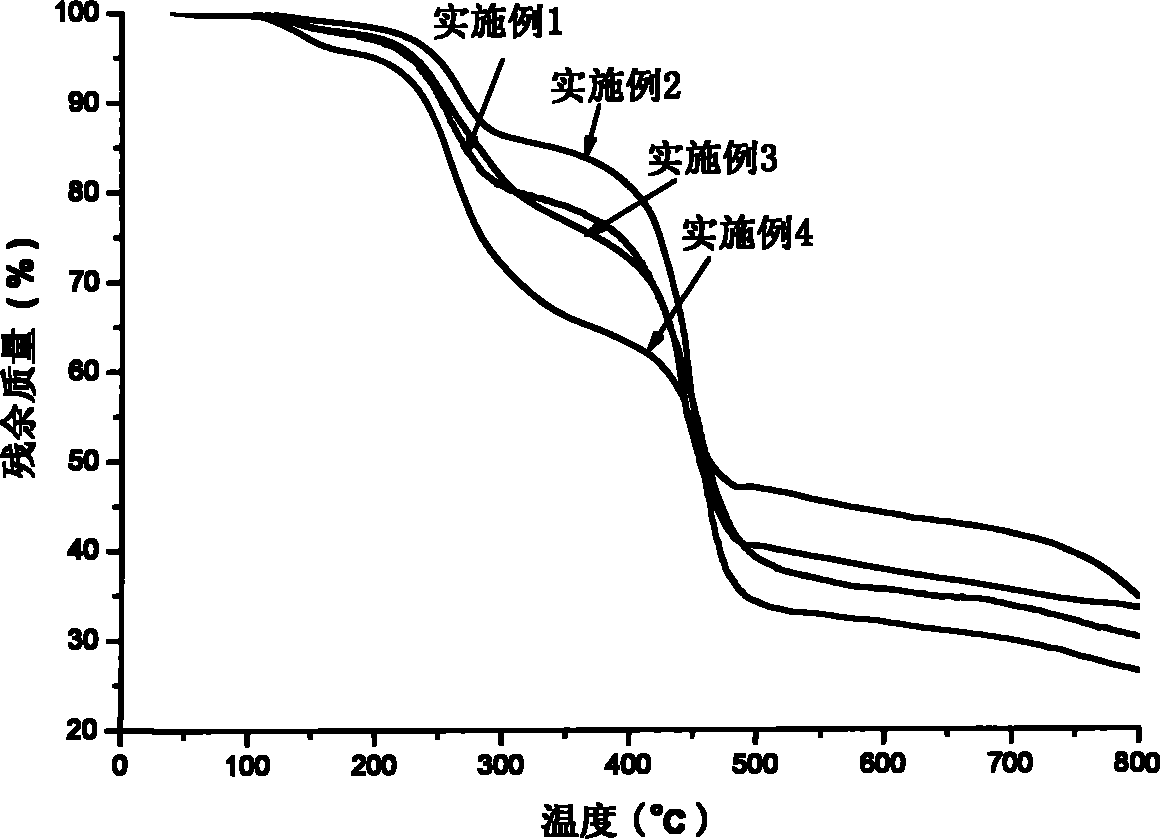

Preparation of polymer solid electrolyte

ActiveCN101440177BEasy to operateEasy to filmFinal product manufactureSecondary cellsEpoxyPolymer science

Owner:上海长宁橡胶制品厂有限公司

A kind of instant fish skin and preparation method thereof

The invention provides ready-to-eat flavored fish skin and a preparation method thereof. The preparation method comprises the following technology steps: (1) macerating fish skin in wine: adding an edible alcohol solution of which the mass is 20-40% as much as the mass of the fish skin and of which the volume concentration is 60-90% to pretreated fish skin; uniformly stirring the pretreated fish skin and the edible alcohol solution so as to obtain a mixture; and placing the mixture in a sealing manner at a room temperature for 30-60 minutes, and then draining the edible alcohol solution so as to obtain wine-macerated fish skin; (2) preserving the wine-macerated fish skin: adding preserving materials to the wine-macerated fish skin obtained in the step (1), and uniformly stirring the preserving materials and the wine-macerated fish skin so as to obtain a new mixture; and preserving the new mixture in a sealing manner at the temperature of 4-15 DEG C for 4-12 hours so as to obtain preserved fish skin; (3) baking the preserved fish skin: baking the preserved fish skin obtained in the step (2) at the temperature of 50-70 DEG C for 20-50 minutes, after baking, cooling the baked fish skin to be room temperature, and then processing the cooled fish skin into slices so as to obtain dried fish skin slices; (4) deep-frying the dried fish skin slices; and (5) removing oil from the deep-fried fish skin slices, seasoning the dried fish skin slices after oil removal, and packaging the seasoned dried fish skin slices. According to the method disclosed by the invention, original color and original nutrition of the fish skin can be reserved to the maximum extent, the mouth feel and the preservation property are improved, and the processing technology is simple and environmental-friendly.

Owner:SICHUAN UNIV

Forming device for flame-retardant strip processing

InactiveCN112428326AAvoid offsetEasy to take outMetal working apparatusCable/conductor manufactureStructural engineeringOpen hole

The invention relates to the technical field of flame-retardant strips, and discloses a forming device for flame-retardant strip processing. The forming device comprises a connecting plate, supportingrods are fixedly connected to the left side and the right side of the top of the connecting plate, the top ends of the two supporting rods are fixedly connected through a fixed plate, and connectingframes are fixedly connected to the bottom of the fixed plate and the top of the connecting plate. The inner walls of the two connecting frames are movably connected through transmission assemblies, limiting rings are fixedly connected to the outer surfaces of the two transmission assemblies, a wire inlet pipe is fixedly installed in the connecting plate on the left side, a supporting block is fixedly connected to the top of the connecting plate, a connecting block is fixedly connected to the left side of the supporting block, limiting plates are fixedly connected to the front face and the back face of the top of the supporting block, and open holes are formed in the top of the supporting block and the interiors of the limiting plates. According to the forming device for flame-retardant strip processing, cutting forming can be carried out conveniently, and the working efficiency is improved.

Owner:扬州高新电缆材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com